As a fabric supplier dealing with global clients daily, I've seen too many orders get stuck not because of price or design, but because of a confusing test report. You receive a fabric shipment, it looks perfect, but then a 20-page document from SGS or Intertek arrives. Your buyer says, "Approve this before we proceed." Your team glances at the tables, numbers, and acronyms – it might as well be another language. This delay costs you time, money, and can even risk the entire order.

Reading a textile test report doesn't have to be a daunting task. In essence, a fabric test report from labs like SGS, ITS, or Intertek is a quality passport for your material. It verifies that your fabric meets specific international safety and performance standards required by your market. Think of it as a detailed health check-up for your textiles, confirming everything from color durability and shrinkage to safety from harmful substances. Understanding it is the key to ensuring quality, avoiding costly rejections, and speeding up your approval process.

Let's demystify this document together. By the end of this guide, you'll be able to confidently interpret the key sections of a report, communicate effectively with your suppliers and labs, and ensure your fabrics are compliant and customer-ready.

What are the key sections in a fabric test report?

When you first open a report, the amount of information can be overwhelming. However, every report follows a logical structure. Knowing where to look for critical information will save you immense time and help you focus on what truly matters for your specific order and end-use.

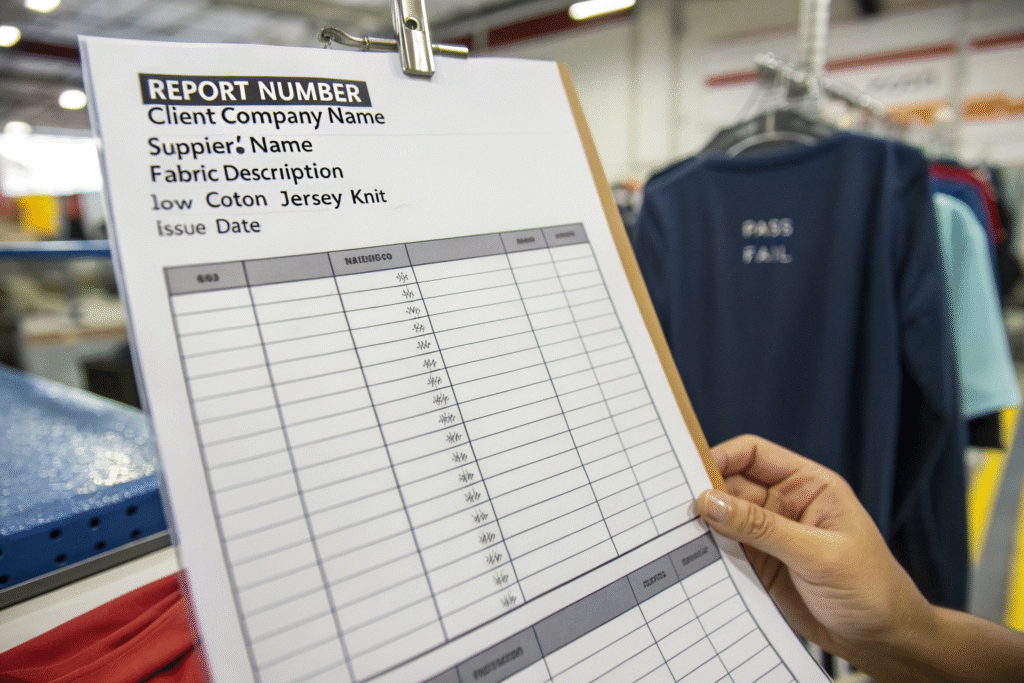

The most important sections are the Header, the Summary of Results, and the Detailed Test Data. The header contains the basic identifying information: the report number, your company name as the client, the supplier's name, a description of the sample (e.g., "100% Cotton Jersey Knit"), and the date of issue. Always double-check this section for accuracy. A simple mistake in the client name or fabric description can lead to approval for the wrong batch. The Summary of Results is your quick health check. It often uses symbols like 'P' for Pass, 'F' for Fail, or a simple color-coding system. A clean pass here is your primary goal. The Detailed Test Data is where you dive deeper to understand the fabric's performance characteristics.

What information is found in the report header?

The header is the identity card of the report. It includes the unique test report number, which is essential for tracking and verification. You will also find the names and addresses of the client (you or your company) and the manufacturer or supplier (like us at Fumao Textiles). The sample description is critical – it must match the fabric you received. This section also states the test methods and standards used, such as ISO standards or AATCC methods, which are the rulebooks for the tests performed. Finally, the date of issue tells you how current the report is. For ongoing business, ensure your reports are recent, typically within a year, to be valid for most buyers.

How do you interpret the summary and detailed data?

The Summary of Results gives you an at-a-glance status. If you see a 'Fail' here, you must immediately go to the Detailed Test Data section to find out why. The detailed data presents numerical results against the required limits or standards. For example, a test for colorfastness to washing will show a grade on a scale of 1 to 5, with 5 being the best. The report will list the result your fabric achieved and the minimum pass requirement. It's not just about passing or failing; the specific numbers tell you about the quality level. A grade of 4 is good, but a grade of 4.5 is excellent and indicates a higher-quality dyeing process.

How to understand fabric composition and performance tests?

This section is the core of the report, detailing what the fabric is made of and how it will behave in real-world conditions. Getting this right is fundamental to product performance and customer satisfaction.

Fabric composition confirms the material you paid for is the material you received. Performance tests simulate the stresses the fabric will endure during its lifecycle, from washing and wearing to environmental exposure. For us at Fumao, with our CNAS-certified lab, we pre-emptively run these tests to ensure a 98% client pass rate, saving our partners like you from unexpected surprises.

What does a composition analysis verify?

A composition analysis verifies the fiber content of your fabric. This is a fundamental truth test. If you ordered 100% organic cotton, the report must confirm that. It detects any undisclosed blends or impurities. This is crucial for labeling laws in countries like the US and those in the EU, where mislabeling can result in heavy fines. The test uses methods like chemical testing or microscopy to identify fibers such as cotton, polyester, wool, or regenerated cellulose like Tencel™. For blends, it will provide the exact percentage of each fiber, ensuring the supplier has delivered the correct specification that impacts the fabric's feel, performance, and cost.

How are colorfastness and durability measured?

Colorfastness and durability are key indicators of how well a garment will age. Colorfastness tests measure the resistance of the fabric's color to various agents like washing, rubbing (crocking), light, and perspiration. They are graded on a scale from 1 (poor) to 5 (excellent).

- Colorfastness to Washing: Ensures the color doesn't run or stain other garments in the wash.

- Colorfastness to Rubbing: Checks if color transfers when the fabric is rubbed against another surface.

- Colorfastness to Light: Vital for outdoor apparel and home textiles, measuring resistance to fading from sunlight.

Durability includes tests like:

- Tensile Strength: Measures how much force is needed to tear the fabric.

- Tear Strength: Measures resistance to the propagation of a tear.

- Seam Slippage: Tests if the stitches in a seam hold under stress.

| Test Type | Standard Method (Example) | Good Performance Grade | What a Low Grade Means |

|---|---|---|---|

| Colorfastness to Wash | AATCC 61 | 4-5 | Color bleeds in laundry |

| Colorfastness to Rubbing | ISO 105-X12 | 4 (Dry) / 3 (Wet) | Color stains other surfaces |

| Colorfastness to Light | AATCC 16 | 4+ for curtains | Fabric fades quickly in sun |

| Tear Strength | ASTM D1424 | > 10N (varies by fabric) | Fabric rips easily |

What do safety and chemical test results mean?

This is non-negotiable, especially for brands in the US and EU. This section ensures the fabric is safe for human skin and the environment, free from harmful levels of regulated substances.

Failing a safety test can lead to a full order recall, massive financial loss, and brand reputation damage. As a supplier deeply invested in sustainability, with significant green investments and compliance with EU eco-certifications, we at Fumao prioritize these tests. We use advanced QR code tracking to provide real-time access to this data, giving you peace of mind.

How to check for harmful substances compliance?

This section lists the concentration of specific chemical substances. Key regulations to look for include:

- REACH (EU): Restricts hundreds of Substances of Very High Concern (SVHCs), such as certain dyes and heavy metals.

- OEKO-TEX® Standard 100: A well-known certification that tests for a wide range of harmful substances.

- CPSIA (USA): For children's wear, it strictly limits lead and phthalates.

The report will list each substance, the method used, the result (e.g., "< 10 mg/kg"), and the limit. The result must be below the limit to pass. For instance, if the limit for formaldehyde is 75 mg/kg for direct skin contact, your result must be less than that. We ensure our fabrics, especially our eco-friendly lines like recycled polyester and BAMSILK, are rigorously tested to meet these stringent standards.

Why are pH and allergen tests critical?

The pH test measures the acidity or alkalinity of the fabric. Human skin has a natural pH of around 5.5. A fabric with a highly acidic or alkaline pH (outside the range of 4.0-7.5 for most standards) can cause skin irritation, dermatitis, or allergies. It's a simple test but vital for comfort. Allergen tests look for specific residue chemicals known to cause allergic reactions, such as certain dispersed dyes (used on polyester and acetate) or nickel residues from accessories. A "ND" (Not Detected) result for these specific allergens is what you want to see for skin-safe clothing.

How to handle a failed test report?

No supplier is perfect 100% of the time, but a professional supplier's response to a failure defines their reliability. A failed report is not the end of the road; it's a problem-solving starting point.

At Fumao, our agile R&D and dedicated QC team view a failure as immediate feedback. It triggers a root-cause analysis, often in our own lab, to identify if the issue was in the dyeing, finishing, or fiber stage. We then provide a corrective action plan and produce a new batch for re-testing, all within a tight timeframe to minimize disruption to your schedule.

What are the first steps after a failure?

First, don't panic. Contact your supplier immediately with the specific failed test items. A professional supplier will not be defensive but will work with you to investigate. The second step is to verify the sample that was tested. Confirm it was from the correct production batch. The third step is to understand the margin of failure. Was it a slight deviation or a major non-compliance? This helps assess the severity. Finally, discuss the potential impact on your end-product. A slight failure in tear strength for a blouse might be acceptable, but the same failure for workwear is not.

How can you prevent future test failures?

Prevention is always better than cure. Partner with suppliers who have in-house testing capabilities, like our CNAS-accredited lab. This allows for pre-shipment testing, catching issues before the bulk order is even shipped. Be extremely clear about your end-market and the required standards in your purchase order. Finally, build a relationship with your supplier. At Fumao, we see ourselves as partners. We use AI-driven trend analysis not just for design but to stay ahead of evolving global compliance regulations, ensuring the fabrics we develop for you are built to pass from the ground up.

Conclusion

Understanding a textile test report is a powerful skill that transforms a confusing document into a strategic tool for quality assurance. It empowers you to verify claims, ensure compliance, and protect your brand. By focusing on the key sections—header, summary, composition, performance, and safety data—you can make informed decisions, approve shipments with confidence, and build stronger, more transparent relationships with your suppliers.

This knowledge turns a potential bottleneck into a smooth pathway for getting quality products to market faster. You now have the blueprint to navigate reports from SGS, Intertek, and ITS effectively. If you're looking for a fabric partner that prioritizes transparency, rigorous pre-shipment testing, and seamless compliance to streamline your sourcing process, let's talk. We at Fumao Textiles are ready to help you ensure every order meets the highest standards. For a reliable partnership on your next clothing order, please reach out to our Business Director, Elaine, at elaine@fumaoclothing.com.