Boron Nitride Nanotube (BNNT) reinforced fabrics are gaining attention in high-performance industries. Many buyers feel the pressure of finding suppliers that can deliver both innovation and reliability. The problem often lies in lack of transparency in sourcing, inconsistent quality, and complex logistics. These concerns make sourcing BNNT fabrics from Asia or global suppliers feel risky.

The way to source BNNT reinforced fabrics is to focus on three critical points: understanding the manufacturing process, identifying reliable suppliers, ensuring compliance with quality standards, and planning for smooth import procedures. By breaking down each step, buyers reduce risks and unlock the advantages of next-generation performance textiles.

When I first started exploring nanomaterial fabrics for our business, I also worried about cost, quality assurance, and certifications. Over time, by testing different suppliers and verifying their credentials, I built a framework that others can follow. In this article, I will share the same sourcing strategy that works for companies, designers, and fabric buyers worldwide.

What is BNNT-Reinforced Fabric Manufacturing Process?

The use of BNNTs in textiles is still emerging, but buyers want to know how these fabrics are made before investing. Many misunderstandings exist about whether BNNT fabrics are produced like normal polyester or cotton. The truth is, BNNTs require a hybrid process that integrates nanomaterials into yarns before weaving or coating.

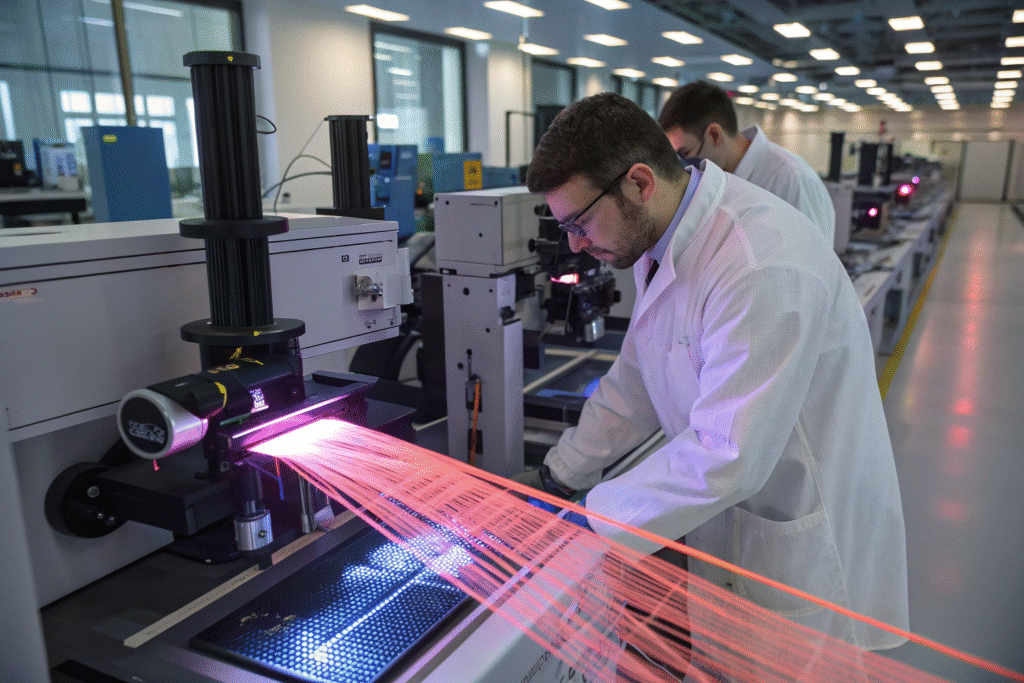

BNNT-reinforced fabric manufacturing involves dispersing boron nitride nanotubes into polymer matrices or blending them into yarns. These fibers are then woven or knitted into fabrics, enhancing thermal conductivity, flame resistance, and mechanical strength. The process ensures nanomaterials are evenly distributed, avoiding clumping while retaining flexibility for textile applications.

BNNT-reinforced textiles start from nanotube synthesis. After purification, BNNTs are treated to improve compatibility with polymers such as polyimide or epoxy resins. These polymer blends are spun into yarns using extrusion. Some suppliers also apply BNNT coatings through chemical vapor deposition (CVD) or solution dipping.

How are BNNTs integrated into textile fibers?

The integration process depends on the desired property. For instance, when targeting thermal resistance, BNNTs are aligned with polymer chains during melt extrusion. When focusing on strength enhancement, they are randomly dispersed but chemically bonded to fiber surfaces. Scientific studies in journals like Nature Materials highlight that uniform dispersion is the key challenge in nanocomposite textiles.

Why does BNNT fabric production cost more?

BNNT synthesis is still expensive because of the high-temperature plasma arc or laser ablation methods. While production has scaled, costs remain higher compared to carbon nanotube fabrics. However, the payoff lies in unique properties like oxidation resistance at 900°C and biocompatibility for medical applications. These benefits justify the investment for aerospace, defense, and advanced apparel.

Which Suppliers Offer BNNT-Reinforced Fabrics?

The challenge many buyers face is finding trustworthy suppliers. On platforms like Alibaba or trade fairs, information about BNNTs often looks vague. Without proper vetting, buyers risk ending up with mislabeled carbon nanotube fabrics instead of genuine BNNTs.

The most reliable suppliers of BNNT fabrics are specialized nanomaterial companies, advanced textile manufacturers in Asia, and research-backed startups in the U.S. and Europe. Buyers should verify suppliers’ patents, certifications, and references before placing large orders.

In my experience, approaching established nanomaterial firms like BNNT LLC or advanced textile divisions of large chemical companies yields better results. Some Chinese and Korean manufacturers are also scaling BNNT integration into woven fabrics for aerospace and defense contracts.

How to identify genuine BNNT fabric suppliers?

The first step is requesting material safety data sheets (MSDS) and independent lab testing. Buyers should check if suppliers have partnerships with universities or R&D labs. Platforms like Nanowerk list nanotechnology suppliers, which helps filter out fake claims.

Where can buyers meet BNNT suppliers directly?

Trade shows such as Techtextil Frankfurt or Nanotech Tokyo are ideal for connecting with BNNT fabric developers. At these events, I noticed suppliers tend to showcase test swatches rather than mass-produced rolls. For serious buyers, visiting the factory is still the best method to confirm capacity.

What Quality Standards Guide BNNT-Fabric Testing?

High-performance fabrics cannot be sourced without clear testing standards. Many buyers underestimate this part and face shipment rejections at customs. BNNT fabrics need both traditional textile quality checks and advanced nanomaterial certifications.

BNNT fabrics must comply with ISO textile standards, ASTM nanomaterial test methods, and safety certifications like REACH and RoHS. Buyers should require tensile strength, thermal stability, and biocompatibility reports before finalizing contracts.

When I negotiated with a European buyer, they insisted on OEKO-TEX Standard 100 certification even for BNNT fabrics. This surprised me, but it made sense since end consumers value eco-compliance. In aerospace, ASTM D3039 tensile tests and ISO 14130 shear tests are mandatory.

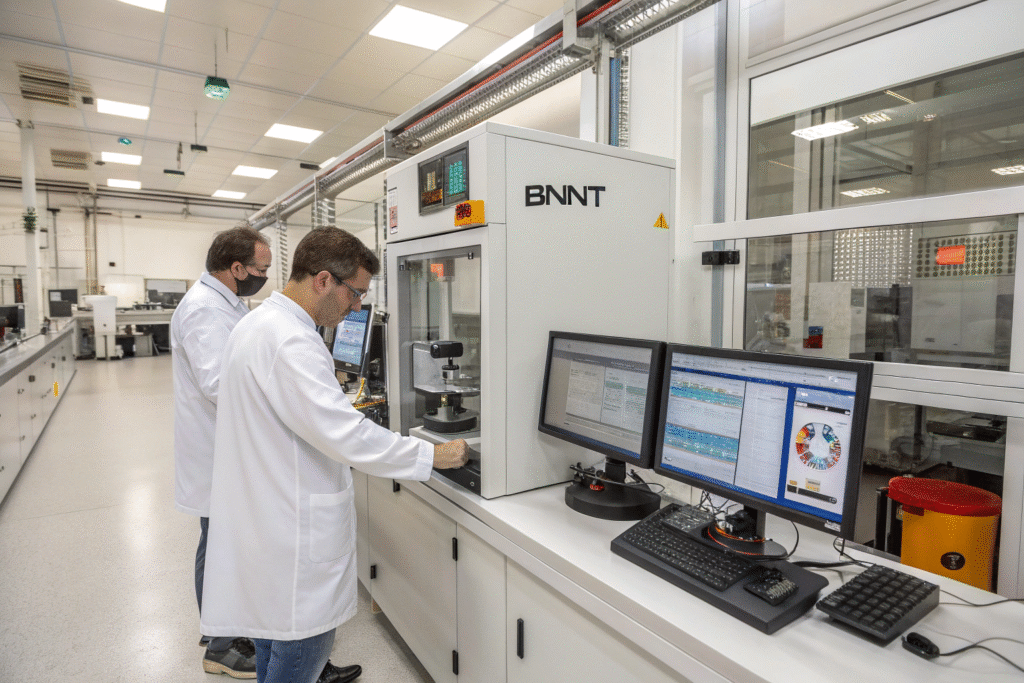

What lab tests are critical for BNNT fabrics?

- Tensile & Flexural Strength: Measured by ASTM standards.

- Thermal Resistance: Tested under ISO protocols for high-temperature fabrics.

- Nanomaterial Dispersion Analysis: Verified by scanning electron microscopy (SEM).

- Toxicity Tests: Ensuring compliance with EU REACH regulations.

How can buyers verify quality before shipping?

The best practice is hiring third-party labs like SGS or Intertek to audit shipments. In China, we also run in-house CNAS-certified testing before export. These steps reassure buyers that their fabrics will not face recalls or compliance issues.

How to Import BNNT Fabrics to the U.S. Seamlessly?

Even after securing a supplier, buyers worry about logistics. Many fear delays due to customs or unexpected tariff charges. For advanced materials like BNNT fabrics, paperwork must be precise.

The easiest way to import BNNT fabrics into the U.S. is to work with logistics companies experienced in nanomaterials, ensure HS codes are correct, and prepare compliance documents like MSDS and test reports. Partnering with reliable freight forwarders reduces delays and costs.

From my shipments, I learned that BNNT fabrics often fall under composite or technical textile HS codes. Using the wrong code results in customs holds. Working with forwarders who specialize in chemical textiles, such as DHL Global Forwarding, ensures smooth clearance.

What documents are required for U.S. import?

- Commercial Invoice & Packing List

- HS Code Classification

- MSDS & Compliance Certificates

- Bill of Lading or Air Waybill

How to minimize tariff and logistics costs?

Some buyers route shipments through bonded warehouses or free trade zones. Others negotiate with suppliers for DDP (Delivered Duty Paid) terms. Working with companies familiar with U.S. trade policies, such as FedEx Trade Networks, reduces both time and cost.

Conclusion

Sourcing Boron Nitride Nanotube reinforced fabrics requires a structured approach: understand the manufacturing process, vet suppliers carefully, ensure strict testing standards, and handle import logistics professionally. By following these steps, buyers can access high-performance textiles with confidence.

If you are ready to explore advanced fabric sourcing with a trusted partner, contact Shanghai Fumao to develop your BNNT or other textile orders. Our Business Director, Elaine, is available at elaine@fumaoclothing.com to guide you through sampling, bulk production, and smooth global delivery.