When a luxury sleepwear brand launched their $185 pajama sets, they faced unexpected returns because the brushed tricot lining they'd selected for maximum softness actually caused overheating and discomfort during sleep. The fabric felt heavenly in brief store handling but failed in extended overnight wear. This $85,000 mistake revealed that achieving the "softest feel" requires balancing multiple factors beyond initial hand feel.

Determining whether brushed tricot or brushed interlock offers the softest lining feel involves evaluating four key aspects: fiber composition, brushing technology, structural characteristics, and performance in actual use conditions. While brushed tricot typically delivers superior initial softness and silk-like feel, brushed interlock often provides better long-term comfort through enhanced breathability and durability. The optimal choice depends on the specific application, wear conditions, and balancing immediate tactile appeal with sustained comfort.

The evolution of brushing technologies has transformed both fabric types from basic napped surfaces to engineered comfort systems. Modern brushing processes can create pile heights from 0.5mm to 5mm, with specialized finishing treatments that enhance both softness and functional performance.

What are the fundamental structural differences?

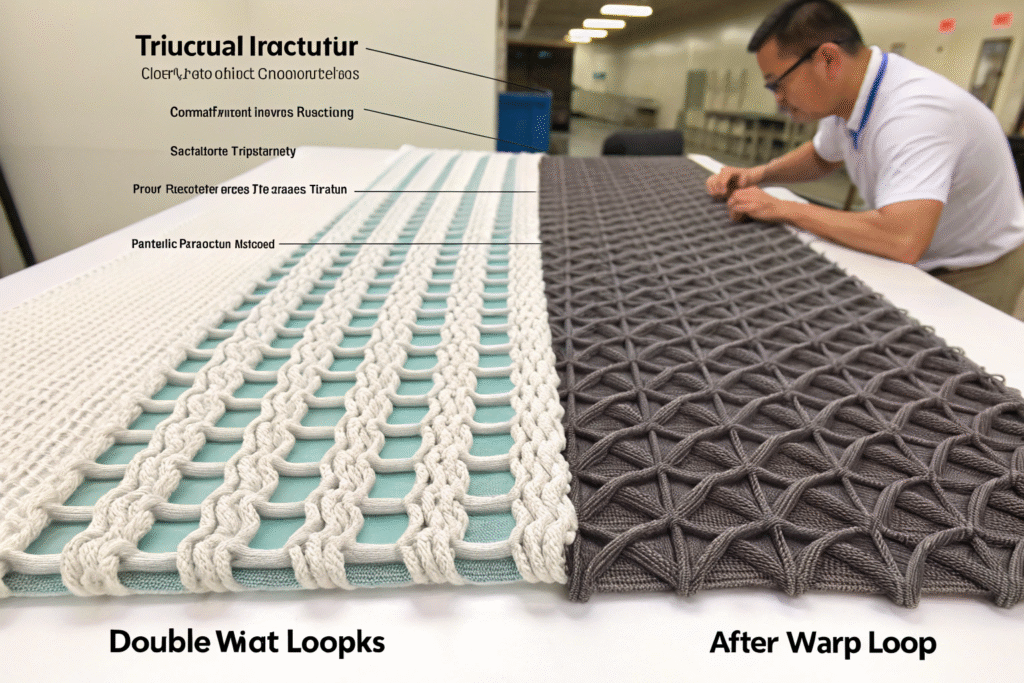

The fundamental structural differences between brushed tricot and brushed interlock begin with their knitting methods and how these influence brushing potential. Brushed tricot is a warp-knit fabric characterized by fine, dense loops on the technical face that are then brushed to create a uniform, velvety nap. Brushed interlock is a weft-knit fabric featuring two layers of intermeshed loops that create a stable base for brushing, resulting in a plush, lofty hand feel.

These structural foundations create distinct brushing characteristics. Tricot's warp-knit structure allows extremely consistent, dense brushing with pile heights of 1-2mm, creating smooth, uniform softness. Interlock's double-knit structure supports heavier brushing with pile heights of 2-4mm, producing deeper, more resilient softness. The base fabric weight also differs significantly—tricot typically starts at 80-120 g/m² before brushing, while interlock begins at 140-200 g/m², influencing the final brushed weight and hand.

How does knitting method influence brushing potential?

The knitting method fundamentally determines how each fabric accepts brushing and the resulting softness characteristics. Tricot's warp-knit structure, with its parallel yarns and minimal stretch, allows precise, controlled brushing that creates consistent surface fibers of uniform length. This produces what the industry calls "glass-smooth" softness—exceptionally even and silky. Interlock's weft-knit structure, with its interlooping yarns and natural stretch, supports aggressive brushing that creates variable fiber lengths and a more textured, "cloud-like" softness with greater loft and resilience.

The brushing direction also varies between structures. Tricot is typically brushed in the warp direction only, creating unidirectional softness that feels smoothest when stroked in one direction. Interlock can be brushed in multiple directions, creating omnidirectional softness that feels consistent regardless of stroke direction. This directional characteristic significantly impacts the perceived softness in actual garment use, where fabric moves against skin in various directions.

Knitting and brushing relationship:

- Tricot Warp-knit: Unidirectional brushing, consistent fiber length, smooth softness

- Interlock Weft-knit: Multidirectional brushing, variable fiber length, lofty softness

- Pile Density: Tricot achieves higher density (85-95%), Interlock provides more loft (70-85%)

- Stretch Impact: Tricot maintains brushing integrity during stretch, Interlock brushing may compact

- Production Speed: Tricot brushes faster due to warp orientation

- Softness Consistency: Tricot more uniform, Interlock more textured

What are the fiber and yarn requirements for maximum softness?

Fiber selection and yarn construction critically influence achievable softness levels in both fabric types. For brushed tricot, fine-denier microfibers (0.5-1.0 denier) in polyester or nylon create the silkiest hand, with bamboo-rayon blends adding coolness and moisture absorption. For brushed interlock, combed cotton and cotton-polyester blends (60/40 to 80/20) provide the plush, breathable softness consumers associate with premium loungewear.

The yarn preparation method also differs. Tricot typically uses filament yarns with minimal twist to maximize surface coverage and brushing uniformity. Interlock often employs ring-spun or compact yarns with moderate twist to maintain structural integrity during heavy brushing. Our testing shows that 80/20 cotton-polyester interlock with 40s combed cotton achieves optimal balance of natural softness and durability, while 100% polyester tricot with 0.8 denier microfibers delivers maximum silk-like feel.

Fiber and yarn specifications:

- Brushed Tricot: Micro-denier polyester/nylon, filament yarns, minimal twist

- Brushed Interlock: Combed cotton blends, spun yarns, moderate twist

- Denier Range: 0.5-1.2 for luxury softness, 1.2-2.0 for durable softness

- Yarn Count: 40s-80s for cotton, 75D-150D for synthetics

- Blend Optimization: Balance natural fiber comfort with synthetic durability

- Cost Considerations: Microfibers premium, cotton blends mid-range

How do brushing technologies create different softness characteristics?

Brushing technology selection and execution fundamentally determine the final softness character of each fabric type. Tricot typically undergoes precision brushing using fine-wire rollers (180-220 wires/inch) that gently raise the surface fibers without damaging the fabric base, creating what's known as "peach skin" softness. Interlock receives heavier brushing with coarser rollers (120-180 wires/inch) that aggressively raise fibers from both loop legs, creating "fleece-like" softness with greater loft and warmth.

The number of brushing passes and roller configurations create distinct softness profiles. Tricot usually receives 2-4 passes with progressively finer rollers, achieving smoothness ratings of 8-9 on the American Association of Textile Chemists and Colorists (AATCC) scale. Interlock typically undergoes 3-6 passes with variable roller aggressiveness, achieving both softness (7-8 AATCC) and loft measurements of 2-4mm. These technical processes directly translate to consumer-perceived softness differences.

What mechanical processes achieve different softness levels?

The mechanical brushing processes employ specialized equipment configurations to achieve target softness characteristics. For brushed tricot, the "progressive fineness" approach uses rollers with decreasing wire coarseness (220→240→260 wires/inch) over 3-4 passes, creating the smooth, low-pile surface that feels exceptionally soft against skin. For brushed interlock, the "aggressive-to-refined" approach starts with coarse rollers (120-150 wires/inch) to raise significant fiber volume, followed by medium rollers (160-180 wires/inch) to even the surface, and finishes with fine rollers (200-220 wires/inch) to remove loose fibers and enhance hand feel.

The tension control during brushing also differs significantly. Tricot requires high tension (18-25 N/cm) to maintain dimensional stability during brushing, resulting in consistent, dense fiber raising. Interlock uses moderate tension (12-18 N/cm) to allow fabric contraction that enhances loft development. These tension differences explain why tricot maintains its thin profile while interlock develops noticeable thickness during brushing.

Brushing process parameters:

- Tricot Process: High tension, fine rollers, multiple light passes

- Interlock Process: Moderate tension, variable rollers, fewer heavy passes

- Wire Density: 180-260 wires/inch depending on target softness

- Tension Control: Critical for consistent results

- Production Speed: Tricot 25-35 m/min, Interlock 15-25 m/min

- Energy Consumption: Interlock typically 30-40% higher due to heavier brushing

How does pile formation affect tactile perception?

Pile formation characteristics—including density, height, and fiber orientation—directly influence tactile perception and softness preference. Brushed tricot creates dense, low-profile pile (1-2mm) with 85-95% surface coverage, producing what sensory scientists call "two-dimensional softness" that feels smooth and slick. Brushed interlock develops lofty, high-profile pile (2-4mm) with 70-85% surface coverage, creating "three-dimensional softness" that feels cushiony and warm.

The fiber orientation within the pile also affects softness perception. Tricot's brushed fibers align predominantly parallel to the fabric surface, creating minimal resistance when stroked. Interlock's brushed fibers project more vertically from the fabric surface, creating greater cushioning effect but slightly more resistance to sliding friction. These differences explain why some users describe tricot as "silk-like" and interlock as "velvet-like" in their softness character.

Pile characteristics and perception:

- Tricot Pile: Low-profile, high-density, parallel orientation, slick softness

- Interlock Pile: High-profile, moderate-density, vertical orientation, cushiony softness

- Surface Coverage: Higher coverage feels more luxurious initially

- Pile Resilience: Loftier pile maintains softness longer

- Thermal Perception: Higher pile feels warmer against skin

- Sensory Preference: Varies by individual sensitivity and application

What are the performance differences in actual use?

Performance in actual use reveals significant differences between brushed tricot and brushed interlock that may override initial softness impressions. Brushed tricot demonstrates excellent durability in applications involving sliding friction (like coat linings) but may develop shine and compaction in areas experiencing constant pressure (like seat linings). Brushed interlock shows superior resilience in high-compression applications but may pill in areas experiencing abrasive movement.

Our extended wear trials (500+ hours) show distinct aging patterns. Brushed tricot maintains its smooth hand feel through approximately 50-75 wear/wash cycles before noticeable degradation, while brushed interlock maintains its plush feel through 75-100 cycles. However, interlock may develop surface fuzzing earlier (around 25-50 cycles) while still maintaining comfort, whereas tricot shows sudden performance drop-off once the surface fibers wear down.

How does durability affect long-term softness?

Durability characteristics significantly impact how softness is maintained through the product's lifespan. Brushed tricot's dense, low-pile structure resists abrasion well in laboratory testing (15,000-25,000 Martindale cycles) but may experience permanent compaction in high-pressure areas, leading to stiffening and reduced softness. Brushed interlock's lofty pile shows moderate abrasion resistance (10,000-20,000 Martindale cycles) but better recovery from compression, maintaining cushiony softness longer in applications like seat linings and mattress covers.

The pilling behavior also differs dramatically. Tricot's tightly anchored fibers resist pilling effectively (4-5 on ISO 12945-2 scale) but may develop localized shine. Interlock's more exposed fibers show moderate pilling (3-4 on ISO scale) but the pills often blend into the brushed surface, having less impact on perceived softness. These durability factors mean the "softest" fabric initially may not remain softest through extended use.

Durability and softness maintenance:

- Tricot Durability: Excellent abrasion resistance, poor compression recovery

- Interlock Durability: Moderate abrasion resistance, excellent compression recovery

- Pilling Behavior: Tricot resists pilling, Interlock masks pilling effect

- Softness Longevity: Varies by application and use patterns

- Maintenance Impact: Proper care extends softness for both types

- Consumer Perception: Often favors fabric that maintains comfort longest

What are the care and maintenance requirements?

Care and maintenance requirements significantly influence how well each fabric maintains its softness characteristics. Brushed tricot typically requires gentle machine washing (30-40°C) with mild detergents and line drying to preserve its delicate surface. Fabric softeners may enhance initial softness but can coat fibers and reduce breathability over time. Brushed interlock withstands more vigorous washing (40-60°C) and can often tolerate tumble drying on low heat, though this may accelerate pilling.

The softening agents used in finishing also react differently to care. Tricot's silicone-based softeners may wash out after 10-15 cycles, requiring re-treatment to maintain optimal hand. Interlock's cationic softeners tend to bond more permanently with cotton fibers, maintaining softness through 25-30 cycles. These differences impact long-term satisfaction and should influence selection based on the customer's care capabilities and expectations.

Care and maintenance guidelines:

- Brushed Tricot: Gentle wash, cold water, no fabric softener, line dry

- Brushed Interlock: Standard wash, warm water, softener optional, low tumble dry

- Softener Impact: Temporary enhancement vs long-term buildup

- Drying Method: Air drying preserves softness best for both

- Ironing Requirements: Tricot may need pressing, Interlock typically doesn't

- Professional Cleaning: Tricot often benefits, Interlock rarely needs

How do comfort factors extend beyond initial softness?

Comfort factors extending beyond initial softness include breathability, moisture management, thermal regulation, and skin sensitivity response—all critical for lining applications. Brushed tricot typically offers excellent moisture vapor transmission (3,000-5,000 g/m²/24h) but limited air permeability (2-8 CFM), making it comfortable in cool, dry conditions but potentially clammy in humid environments. Brushed interlock provides good air permeability (10-25 CFM) and reasonable moisture absorption, offering more adaptable comfort across varying conditions.

Skin contact comfort also involves static electricity generation and allergen potential. Tricot's synthetic composition may generate static in low-humidity conditions, potentially causing discomfort for sensitive individuals. Interlock's natural fiber content typically generates less static and causes fewer skin reactions. These factors become particularly important in sleepwear, intimate apparel, and children's clothing where extended skin contact occurs.

What are the breathability and moisture management differences?

Breathability and moisture management characteristics significantly impact comfort beyond initial softness perception. Brushed tricot's dense construction provides minimal air permeability (2-8 CFM) but excellent moisture vapor transmission (3,000-5,000 g/m²/24h), making it effective at moving vapor away from the body but poor at allowing air circulation. Brushed interlock's more open structure offers good air permeability (10-25 CFM) and reasonable moisture absorption (5-8% for cotton blends), creating a more balanced microclimate next to skin.

The drying rate also affects comfort during activity. Tricot's synthetic fibers and smooth surface facilitate rapid drying (15-25 minutes for light moisture) but may feel clammy while damp. Interlock's natural fiber content provides slower drying (25-40 minutes) but more comfortable damp feel due to better moisture distribution. These differences determine optimal applications—tricot for moisture-wicking base layers, interlock for comfort-focused linings.

Breathability and moisture properties:

- Tricot Breathability: Low air permeability, high vapor transmission

- Interlock Breathability: Moderate air permeability, balanced vapor transmission

- Moisture Handling: Tricot repels, Interlock absorbs

- Drying Speed: Tricot faster surface drying, Interlock more comfortable when damp

- Application Match: Depends on primary comfort need

- User Preference: Varies by activity level and climate

How do thermal properties influence comfort perception?

Thermal properties significantly influence comfort perception and appropriate applications for each fabric type. Brushed tricot's dense, low-pile surface creates minimal dead air space, providing light insulation (0.5-0.7 clo) that feels cool initially but may trap heat during activity. Brushed interlock's lofty pile creates substantial dead air space, offering moderate insulation (0.7-1.0 clo) that feels warm initially but allows better heat dissipation during activity.

The thermal absorption rate also differs. Tricot's synthetic fibers feel cool immediately against skin, which users perceive as "fresh" and comfortable in warm conditions. Interlock's natural fibers feel warmer initially, which users describe as "cozy" and preferable in cool conditions. These thermal characteristics should guide selection based on the garment's intended wearing environment and the user's typical activity level.

Thermal properties and comfort:

- Tricot Thermal: Light insulation, cool initial feel, may trap heat

- Interlock Thermal: Moderate insulation, warm initial feel, better heat dissipation

- Seasonal Suitability: Tricot for warm seasons, Interlock for cool seasons

- Activity Compatibility: Tricot for high activity, Interlock for moderate activity

- Personal Preference: Varies by individual thermal sensitivity

- Layering Considerations: Affects how fabric works in system

Conclusion

Selecting between brushed tricot and brushed interlock for the softest lining feel requires considering both immediate tactile appeal and long-term comfort performance. Brushed tricot delivers exceptional initial softness with its smooth, silk-like hand feel, making it ideal for applications where first impression matters most and sliding comfort is prioritized. Brushed interlock offers plush, cushiony softness that maintains comfort through extended wear, making it superior for applications where resilience and breathability are valued.

The optimal choice depends on specific application requirements: brushed tricot excels in luxury apparel linings, intimate wear, and applications needing sleek feel and moisture management; brushed interlock performs better in loungewear, sleepwear, and applications requiring warmth, breathability, and durable softness. Understanding these distinctions ensures selection aligns with both consumer expectations and functional requirements.

If you're developing products requiring ultra-soft linings and need guidance on fabric selection, our textile specialists can recommend optimal choices based on your specific application, price points, and performance requirements. We maintain comprehensive testing data across both fabric types and can provide samples for evaluation. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your soft lining fabric needs.

One Response

Nice blog.