When innovators in wearables, robotics, and medical devices search for new solutions, they often encounter the same obstacle: traditional rigid circuits cannot stretch or bend without failing. This creates frustration for product developers who want to build flexible devices but feel limited by outdated materials.

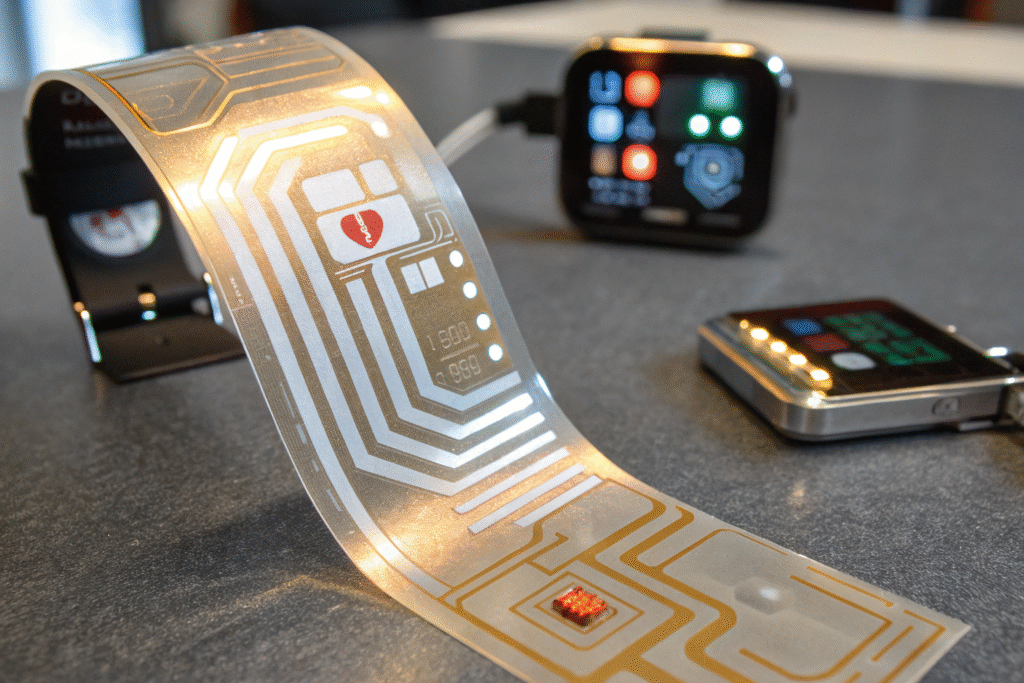

Liquid metal printed stretchable circuits provide the answer. They combine high conductivity with remarkable flexibility, making them ideal for smart clothing, biomedical sensors, flexible displays, and robotics. They are not only durable but also open the door to designs that once seemed impossible.

As industries race toward miniaturization and adaptability, this technology stands at the forefront. Below, I will explore its benefits, applications, manufacturing process, and future potential.

Benefits of Liquid Metal Circuits

Liquid metal circuits represent a shift away from brittle, rigid electronics. They offer conductivity close to copper but with elasticity that allows them to bend and stretch. This unique combination makes them suitable for next-generation electronics.

The greatest benefit is that liquid metal printed stretchable circuits maintain electrical stability even under repeated deformation. They remain reliable when twisted, folded, or stretched, unlike thin metallic films that break under strain.

Why are liquid metal circuits highly durable?

Durability comes from the properties of alloys such as gallium–indium, which flow with movement rather than cracking. As explained by ScienceDirect, liquid metal channels preserve conductivity under stress. Also, Nature Electronics notes that their resistance to oxidation supports long-term stability.

How do liquid metal circuits support miniaturization?

Miniaturization is essential in electronics. With liquid metal printing, conductive lines can be deposited with precision directly on flexible substrates. According to IEEE Spectrum, this allows circuits to be embedded in textiles or thin films. In addition, MDPI Sensors reports that liquid metal circuits integrate multiple functions in compact footprints, helping create smaller and smarter devices.

Applications in Wearable Electronics

Wearables require electronics that can move with the human body. Rigid circuits cannot meet this need. Liquid metal printed circuits make it possible to design comfortable, stretchable, and reliable devices.

They are already used in fitness trackers, biomedical monitors, smart clothing, and advanced VR systems. These circuits give comfort and function without adding bulk.

How do they improve comfort in smart textiles?

By printing directly onto fabrics, liquid metal circuits remove the need for bulky wires. This makes smart clothing feel like normal garments. Textile World explains that fabric-integrated circuits improve design freedom. In addition, ScienceDaily highlights that wash-resistant circuits are making smart textiles practical for daily wear.

Why are they crucial for medical wearables?

Medical wearables must be safe, reliable, and skin-friendly. Liquid metal circuits can flex with the body, allowing accurate monitoring without irritation. According to PubMed, liquid metal biosensors are biocompatible and precise. Also, NIH Research shows that stretchable circuits reduce stress on skin, making long-term use more comfortable for patients.

Manufacturing Process of Liquid Metal Printing

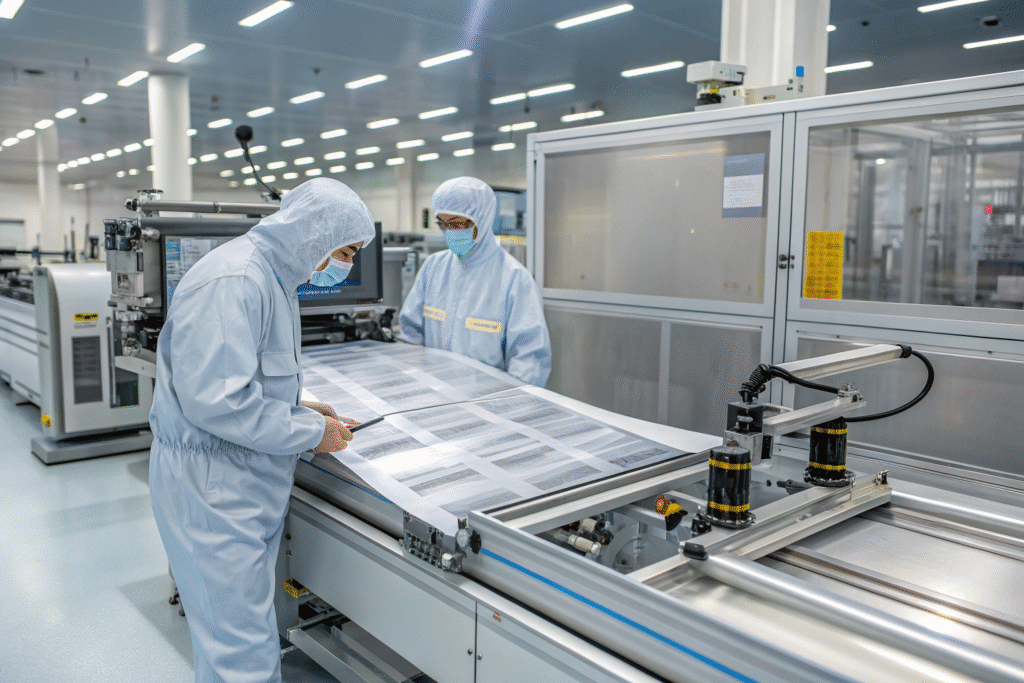

The printing process is surprisingly simple and adaptable. It does not require high-temperature treatments or expensive retooling, making it more efficient than traditional PCB production.

The method includes preparing substrates, printing conductive alloys, and encapsulating for stability. This approach allows both large-scale and custom production at lower cost.

What are the main steps in liquid metal printing?

The process generally includes three steps: surface preparation, liquid alloy printing, and protective sealing. ACS Publications explains how this reduces material waste. Meanwhile, Wiley Online Library describes scalable methods like screen printing and inkjet printing.

How does it enable rapid prototyping?

Since the printing design can be digitally adjusted, prototypes can be made quickly. ResearchGate highlights that no physical molds are required. SpringerLink adds that fast iteration cycles help startups shorten development times and bring products to market faster.

Future of Stretchable Electronics

Stretchable electronics are expected to lead the next wave of innovation. Industries from healthcare to fashion are exploring how to adopt this breakthrough technology.

Liquid metal printed circuits will not replace all rigid PCBs, but they will dominate applications where flexibility and comfort are critical.

Will liquid metal circuits replace traditional PCBs?

Rigid PCBs will remain important, but flexible circuits will gain ground in wearables and robotics. Electronics Weekly predicts fast growth in flexible electronics. At the same time, Tech Xplore points out that hybrid systems combining rigid and stretchable circuits will become standard.

What challenges remain for large-scale adoption?

Large-scale adoption requires better mass-production methods and testing standards. Nature Reviews Materials says improving scalability is key. In addition, Elsevier Journals stress the need for universal reliability benchmarks across industries.

Conclusion

Liquid metal printed stretchable circuits are no longer only a laboratory experiment. They are becoming part of real-world applications in smart textiles, medical wearables, and robotics. Their unique mix of strength, flexibility, and conductivity makes them a powerful choice for innovators.

For businesses that want to explore this technology, now is the right time. Early adopters will have the advantage in markets shaped by stretchable electronics.

If you want to co-develop or produce your own fabric-integrated circuits, you can reach out to our company Shanghai Fumao. Please contact our Business Director Elaine at: elaine@fumaoclothing.com for further collaboration opportunities.