When you are sourcing specialized materials like fluorescent marking tapes that claim compliance with MIL-STD-3009, it can be confusing. Many buyers, especially in aerospace, defense, and tactical industries, struggle to separate ordinary high-visibility safety tapes from true NVIS-compliant materials. The wrong choice can cause project delays, compliance issues, or even safety risks.

MIL-STD-3009 primarily governs NVIS-compatible lighting systems, not general-purpose tapes. This means many products labeled "fluorescent" or "high-visibility" may not actually meet the strict spectral requirements of the standard. Understanding what the standard covers and where to find verified suppliers is essential for procurement teams and engineers.

That’s why in this article, I will guide you through what MIL-STD-3009 really means, how it applies to fluorescent materials, which suppliers actually deliver compliant products, and what to consider before making a purchase.

What Is MIL-STD-3009 and Why Does It Matter?

When we hear MIL-STD-3009, many assume it applies to all luminous materials. In reality, it is a standard that defines how lighting systems should work with night-vision devices (NVGs). It focuses on color spectrum, intensity, and compatibility rather than simply being bright or fluorescent.

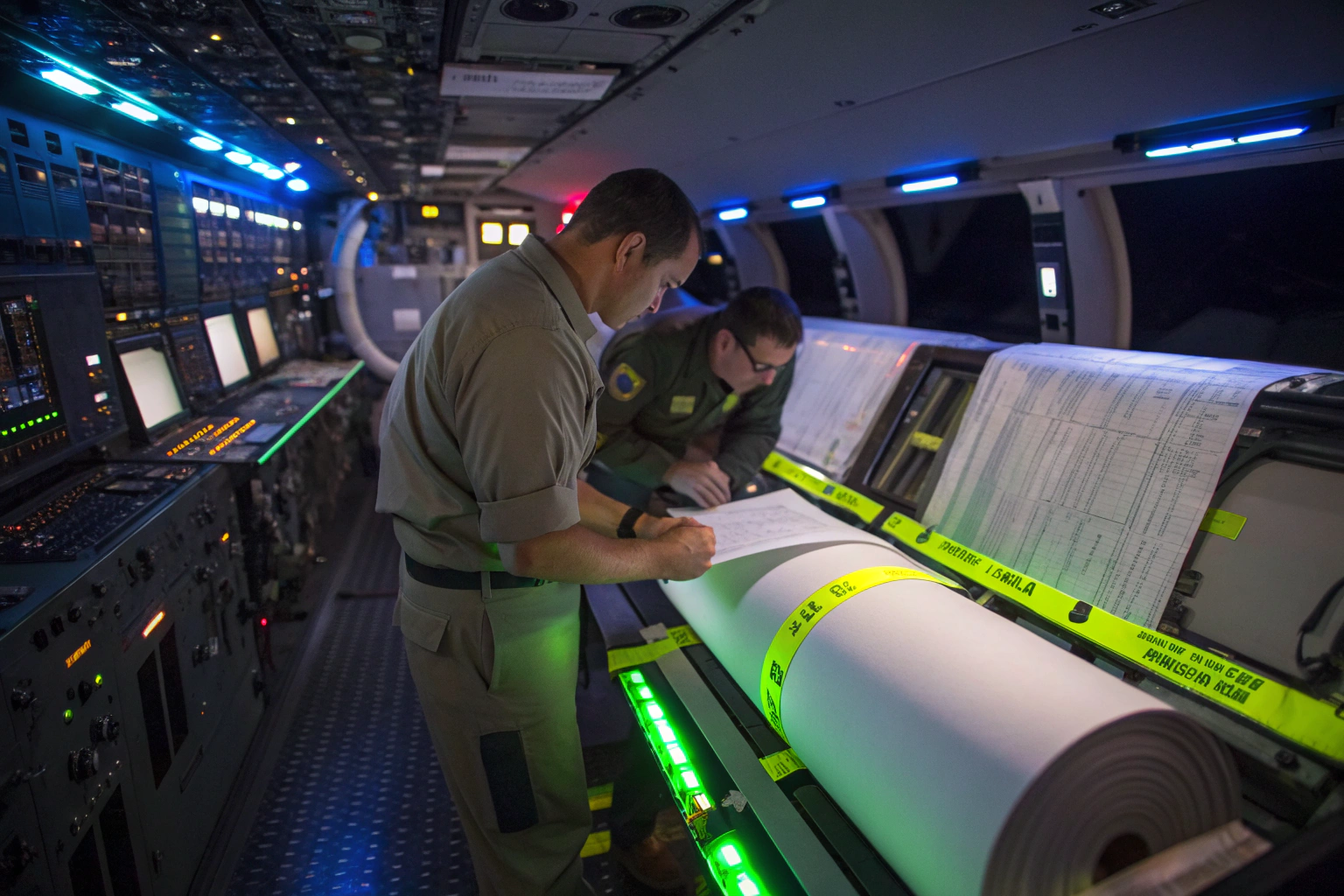

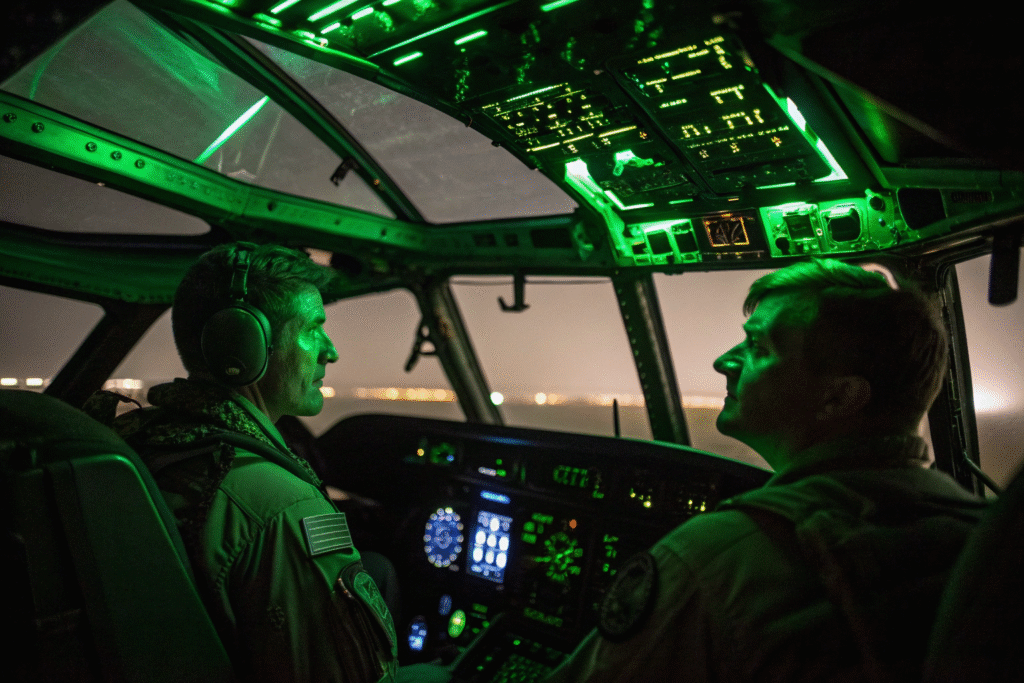

MIL-STD-3009 is critical because it ensures pilots, soldiers, and technicians can see their equipment under NVGs without glare or interference. Without compliance, even a simple marker or indicator could wash out night vision, creating dangerous blind spots in missions.

Is every fluorescent tape MIL-STD-3009 compliant?

No. Most safety tapes you find in commercial markets are made for warehouses or construction sites. They provide high daytime visibility, but they are not engineered for NVIS spectral requirements. For example, bright yellow tapes from 3M Safety Products are excellent for industrial use, but they are not listed as NVG-compatible.

Where does compliance usually apply?

Compliance is usually in cockpit lighting, instrument backlighting, and tactical LEDs. Suppliers like Consolite Technology and Betalight Tactical offer certified MIL-STD-3009 solutions. These are more about filters, panels, and LEDs, not adhesive tapes.

Are There Fluorescent Tapes That Meet Military Standards?

Most fluorescent marking tapes in the market target industrial and commercial applications. They focus on durability, adhesive strength, and visibility under normal light. However, when you need compliance with military standards, the options shrink significantly.

True MIL-STD-3009 compliant materials are rare. Some specialized suppliers develop custom NVIS-compatible tapes or coatings for defense contracts, but these are not typically available in open commercial catalogs.

What are the closest alternatives?

Companies like Brady Corporation and Nitto Denko manufacture high-visibility and photoluminescent tapes used in aerospace interiors. While not always directly certified to MIL-STD-3009, these products often meet related aviation and defense standards.

Can coatings replace tapes?

Yes. In some defense projects, NVIS-compatible coatings are applied instead of tapes. For example, tactical gear makers use NVG-safe paints to achieve the same compliance effect without adhesive film. This makes coatings an important alternative when tapes are not available.

Who Are the Reliable Suppliers for NVIS-Compatible Materials?

Finding the right supplier is not just about buying tape; it is about ensuring NVIS compatibility. Some well-known companies in the NVG compliance space include:

Which companies specialize in MIL-STD-3009 products?

- Consolite Technology (UK): Known for filters, panels, and NVG lighting solutions.

- Betalight Tactical: Strong in NVG-safe LEDs and military applications.

- Sofradir & Safran (France): Work with infrared and NVG systems.

These firms have long histories of working directly with defense projects.

Are there distributors in the U.S.?

Yes. Companies like AeroDefense and Defense Logistics Agency help buyers locate NVIS-compatible materials. They often act as intermediaries for international defense-certified manufacturers.

How to Choose the Right Product for Your Application?

Choosing the correct product depends on whether you truly need NVIS compliance or just fluorescent visibility. This distinction is where many procurement mistakes happen.

What questions should you ask suppliers?

- Can they provide MIL-STD-3009 compliance certificates?

- Do they test spectral output with NVG devices?

- Are the tapes or coatings intended for aviation or ground tactical use?

Asking these questions helps you avoid generic safety tapes that cannot pass military inspections. Reliable suppliers will not hesitate to provide testing data.

What if full compliance is not required?

If you only need fluorescent safety tapes for industrial or warehouse use, then standard options from Avery Dennison or 3M Industrial Safety will work. They are durable, bright, and cost-effective, but you should not confuse them with NVIS materials.

Conclusion

When looking for MIL-STD-3009 compliant fluorescent marking tapes, the key is understanding that the standard covers NVIS lighting systems, not everyday tapes. This means most off-the-shelf fluorescent tapes do not apply. Instead, compliance usually comes from specialized coatings, LEDs, or filters supplied by defense-certified companies.

If you are sourcing materials for aerospace or military projects, I recommend contacting suppliers like Consolite Technology or Betalight Tactical for direct NVIS solutions. For commercial or industrial needs, global brands like 3M, Brady, or Nitto provide reliable fluorescent tapes that excel in visibility but are not NVG compliant.

At Fumao Fabric, we know the challenges of global sourcing and compliance. While we focus on fabrics, coatings, and technical textiles, we understand how crucial it is to select the right material for the right environment. If you need guidance in sourcing or developing compliant fabrics and coatings, reach out to us. You can contact our Business Director Elaine at elaine@fumaoclothing.com to discuss how we can support your project needs.