Sun protection is no longer just about sunscreen—today’s apparel is expected to do more, especially when performance and safety go hand in hand.

New UV-protective fabric technologies now combine higher UPF ratings with stretch, breathability, and eco-friendliness. These advanced textiles offer reliable sun protection without sacrificing comfort or sustainability.

I’ve worked with clients from beachwear startups to large outdoor brands, and their demands have changed fast. It’s no longer just “does this block UV?” It’s “can this stretch, wick, feel light—and still protect?” In this article, I’ll share what’s really new in UV-blocking textiles and how we at Fumao help buyers meet both performance and consumer expectations.

How Effective Are New UV-Protective Fabric Technologies?

Not all sun-blocking textiles are created equal anymore.

Modern UV-protective fabrics offer UPF 50+ performance through fiber composition, finishing agents, and weaving techniques. Many maintain their protection after repeated wash cycles, thanks to embedded or crosslinked technology.

How do the latest UV-blocking fabrics maintain protection even after washing?

Here’s the breakdown of how current UV-protective fabrics outperform older types:

| Technology Type | How It Works | Wash Durability | Breathability | Comfort |

|---|---|---|---|---|

| Embedded Inorganic Additives | Uses titanium dioxide or zinc oxide mixed into fibers | Very High | Medium | Good |

| Chemical Finishing Agents | Surface-treated with UV-absorbers like benzotriazole | Moderate | High | High |

| Dense Weaving Structure | Physical barrier to UV with tightly woven microfibers | High | Medium | Medium |

| Crosslinked Polymers | UV stabilizers locked into the molecular chain | Very High | High | High |

Traditional cotton or rayon might offer a UPF of 5–15. But now, even recycled polyester blends can hit UPF 50+ if processed correctly. We use in-house testing aligned with AS/NZS 4399 and AATCC 183 to validate claims before bulk delivery.

For a recent surfwear project, we blended spandex with TiO2-infused polyamide and achieved UV 98% blockage, with no drop after 20 machine washes. Our U.S. client used the fabric for rash guards that doubled as SPF merchandise.

What should buyers look for when evaluating UV claims?

Don’t just trust hang tags. Ask for:

- UPF test reports (from accredited labs)

- Wash durability results (after 10, 20, 30 cycles)

- Details on how UV resistance is achieved

- Certification alignment (e.g., AATCC, ISO, AS/NZS)

The better suppliers—like Fumao—will document everything, including test method, batch origin, and additive type. That way, you’re not risking lawsuits or complaints over false UV protection claims.

Best UV-Resistant Fabrics for Active Outdoor Wear

Outdoor wear needs protection that stretches, breathes, and holds up in tough conditions.

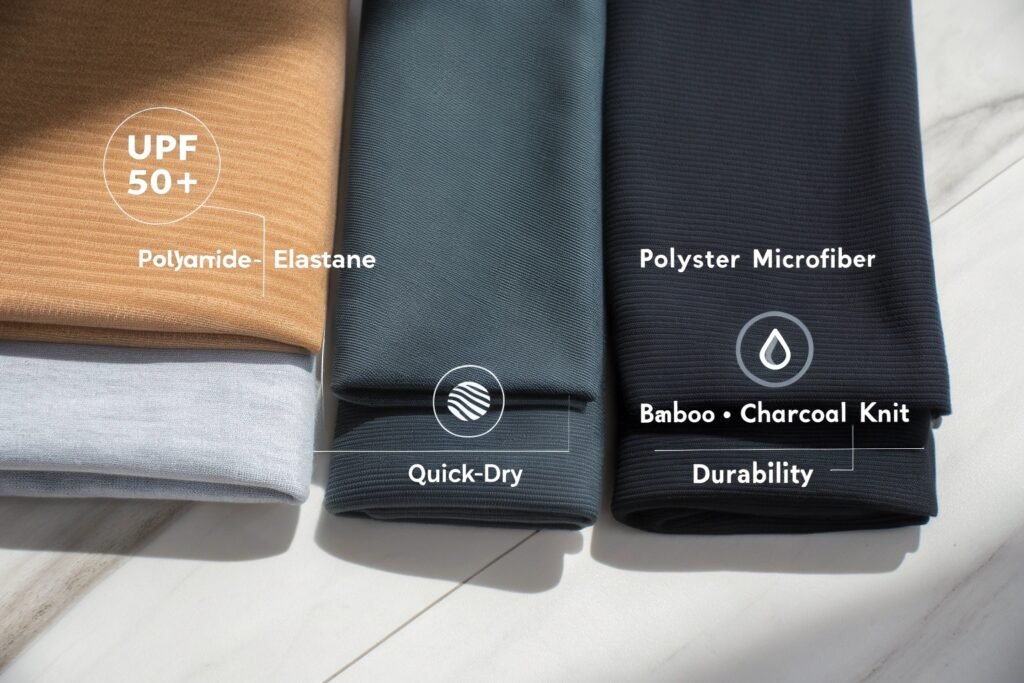

Top UV-resistant fabrics for activewear include polyamide-elastane blends, polyester microfibers, and bamboo-charcoal knits. These fabrics offer UPF 40–50+ and retain their effectiveness after multiple wears and washes.

Which UV fabrics work best for different outdoor use cases?

Here’s a usage-based breakdown:

| Outdoor Activity | Best Fabric Type | Key Benefits |

|---|---|---|

| Hiking | Polyester + Bamboo Charcoal | Breathability, odor control, UPF 45 |

| Surfing | Polyamide + Elastane w/ TiO2 | Stretch, salt resistance, UPF 50+ |

| Running | Micro-poly mesh w/ crosslinked UV | Lightweight, moisture wicking, UPF 40+ |

| Cycling | Nylon + Lycra dense weave | Wind block, tight fit, UPF 50+ |

| Climbing | Softshell poly w/ dense UV knit | Durability, abrasion resistance |

The real trick is balancing UV protection with user comfort. A dense fabric may block UV but trap heat. That’s why we recommend dual-layer knits—an inner layer for moisture transport and an outer UV shield.

We’ve recently developed a new recycled nylon-spandex blend with permanent UV inhibitors embedded at the yarn stage. It’s being tested now in Australia for its 50+ rating under harsh sun exposure.

How do we test UV performance at Fumao?

Our in-house lab follows AATCC 183 and AS/NZS 4399 protocols. We simulate sun exposure using a xenon arc lamp and measure transmittance of UV-A and UV-B wavelengths. Every UV-protective batch comes with:

- UPF rating

- Wavelength absorbance chart

- Wash resistance index

- Lightfastness crossover (especially for dyed performance fabrics)

So, you’re not just buying a tag—you’re buying science-backed defense for your customers.

Trends in Sustainable UV-Protective Textiles?

Sun-safe fabrics now need to be eco-safe, too.

Sustainable UV-protective textiles are now incorporating recycled yarns, plant-based finishes, and biodegradable fibers—without sacrificing UPF performance. Blends of rPET, bamboo, and modal with mineral UV additives are leading the trend.

How are eco-conscious brands redefining UV performance?

In the past, sustainability and UV resistance were hard to combine. UV-blocking agents like nano-zinc or chemical absorbers weren’t always biodegradable or skin-safe. But today, the game has changed.

Here are four green innovations in UV textiles:

- Recycled Polyester (rPET) + Embedded TiO₂: Durable, low-energy production, consistent UPF 50+

- Tencel™ Modal + Plant-Based UV Coating: Breathable, compostable, UPF 35–40

- Bamboo Rayon + Charcoal Infusion: Naturally UV absorbent, odor-resistant, soft

- Biodegradable Nylon + UV Finish: Still under development, but showing UPF 30–40

At Fumao, we’ve created several custom fabrics using recycled ocean plastic polyester blended with crosslinked UV stabilizers. They’re soft, printable, and certified by GRS and OEKO-TEX.

Here’s how one of our clients used it:

| Brand Goal | Fumao Fabric Solution |

|---|---|

| Launch UPF swimwear | rPET + elastane w/ embedded zinc oxide |

| Require GRS certification | Full traceability to bottle source |

| Avoid post-finishing | Yarn-level additive = lower footprint |

| Sell in EU & U.S. | Passed AS/NZS + AATCC UPF testing |

They marketed it as “Ocean-Proof. Planet-Safe.” And it worked. Retailers loved the traceability and performance combo.

Why Athleisure Brands Prefer Advanced UV Fabrics?

Because outdoor is now everyday—and protection sells.

Athleisure brands are choosing advanced UV fabrics for multi-functional wear, combining protection, stretch, softness, and style. These textiles meet both performance and lifestyle demands, boosting value and consumer trust.

Why is UV protection becoming a baseline in fashion-forward activewear?

Today’s consumer wants a jogger that feels like silk, dries fast, blocks UV, and looks sharp. That’s where UV fabrics come in.

Key selling points for athleisure buyers:

- Multi-functional: UV + anti-odor + moisture-wicking

- Urban-to-nature versatility: Stylish enough for city, tough enough for trails

- Value-added: UPF 50+ is a tag-worthy claim

- Layer-friendly: Lightweight UV protection fits under outerwear

Athleisure buyers are no longer asking “do you have UV options?” They’re expecting it as standard. Many buyers we serve also request dual-finish surfaces—matte for fashion, mesh interior for comfort.

Fumao developed a micro-jersey UV knit for a European yoga brand. It had a heathered look, buttery soft touch, UPF 45+, and stretch recovery even after 50 washes. The product became their top-selling sun-safe top in two markets.

What are the strategic advantages of sourcing UV fabric from Fumao?

- Rapid sampling (48h): Our in-house R&D can blend performance yarns fast.

- Certified testing: CNAS-accredited lab validation on every UV batch.

- Eco-focus: We offer GRS and OEKO-TEX fabrics with proven UV performance.

- MOQ Flexibility: We support low-volume launches and bulk scaling.

When you need UV protection that does more than protect—Fumao makes it easy.

Conclusion

UV-protective fabrics have evolved from niche to necessity. Today’s best materials defend against sun, stretch with movement, and support sustainability. Fumao stays ahead by combining performance science with global textile expertise—so your apparel lines never fall behind.