Consumers are no longer just shopping for looks—they’re buying values. And sustainability is becoming the defining value for modern fashion. In the swimwear sector, recycled nylon is making waves, both literally and economically. But what’s behind this shift? The answer lies at the intersection of consumer consciousness, technology, and global trade trends.

Recycled nylon has quickly moved from being a niche option to a mainstream material in the swimwear market. Its appeal lies in performance, aesthetics, and ethics—delivering the same elasticity and durability as virgin nylon while reducing ocean and landfill waste. Brands from startup swim labels to legacy names are now investing in recycled yarns, positioning sustainability not just as a choice, but a competitive edge.

More than a trend, this change signals a deeper transformation in how swimwear is made, sourced, and perceived. From eco-certifications to circular economy practices, recycled nylon is the material buyers are watching. Let’s explore the powerful factors fueling its rise.

Why Are Swimwear Brands Switching to Recycled Nylon?

Recycled nylon isn't just good for the planet—it’s good for business. The swimwear industry has long depended on nylon for its stretch, resistance, and quick-drying nature. Now, eco-friendly recycled alternatives offer the same function without the environmental guilt.

Swimwear brands are switching to recycled nylon to meet growing customer demand for sustainability while preserving performance quality. Certifications like GRS (Global Recycled Standard) help validate claims, and leading factories offer consistent quality that rivals virgin fiber.

What Sustainability Goals Are Driving Material Choices?

For many swimwear brands, using recycled nylon supports their ESG (Environmental, Social, and Governance) targets. With younger consumers valuing climate responsibility, even fast-fashion players are rolling out green capsule lines. In this context, sourcing matters just as much as style.

Brands now include sustainability metrics in product development cycles. Certifications like OEKO-TEX® and supply transparency are no longer optional—they're expectations. Recycled nylon aligns with these demands, reducing reliance on fossil-based synthetics while fitting seamlessly into activewear collections.

How Is Marketing Impacting Material Adoption?

Recycled nylon is easy to promote. Brands highlight stories of “plastic bottles turned into bikinis” or “ocean nets reborn into fashion.” These narratives resonate with both online shoppers and boutique buyers. It turns material sourcing into a storytelling opportunity—a key in an era where authentic brand values drive sales.

These stories also increase perceived value. A sustainable swimsuit can be priced higher, supported by the material story. This boosts profit margins while reducing ecological footprint—a win-win.

What Are the Advantages of Recycled Nylon in Performance?

Swimwear isn’t just about looks—it’s about how it holds up in water, salt, chlorine, and sun. Recycled nylon has proven itself to match virgin nylon’s toughness and flexibility.

Recycled nylon delivers on durability, UV protection, and elasticity—core performance features critical for swimwear. It behaves identically in wear trials, making it a dependable material for both technical and fashion swimwear.

Can Recycled Nylon Withstand Chlorine and UV Exposure?

Yes. Technical processing ensures that recycled nylon fibers are treated with protective coatings that enhance their chlorine resistance and UV protection levels. In our lab at Fumao, we run accelerated UV stability tests on every recycled lot to ensure they meet global swimwear performance benchmarks.

Manufacturers also blend recycled nylon with spandex or elastane for long-lasting stretch, critical for athletic or compression swimwear. These blends maintain shape retention even after repeated dips in chlorine pools.

Is There a Difference in Hand Feel or Print Quality?

Recycled nylon’s texture is comparable to virgin yarns, often offering slightly softer finishes due to post-processing techniques. This makes it ideal for both solid-dyed and digitally printed swimwear.

We’ve found that eco-print inks adhere excellently to recycled surfaces, maintaining color brilliance across prints. High-resolution printing and heat transfer methods—used in sublimation printing—are fully compatible with our recycled fabrics.

How Do Certifications and Traceability Affect Buyer Trust?

In a market wary of greenwashing, certifications offer proof. Traceability is no longer a bonus—it’s a must for serious buyers in the EU and US.

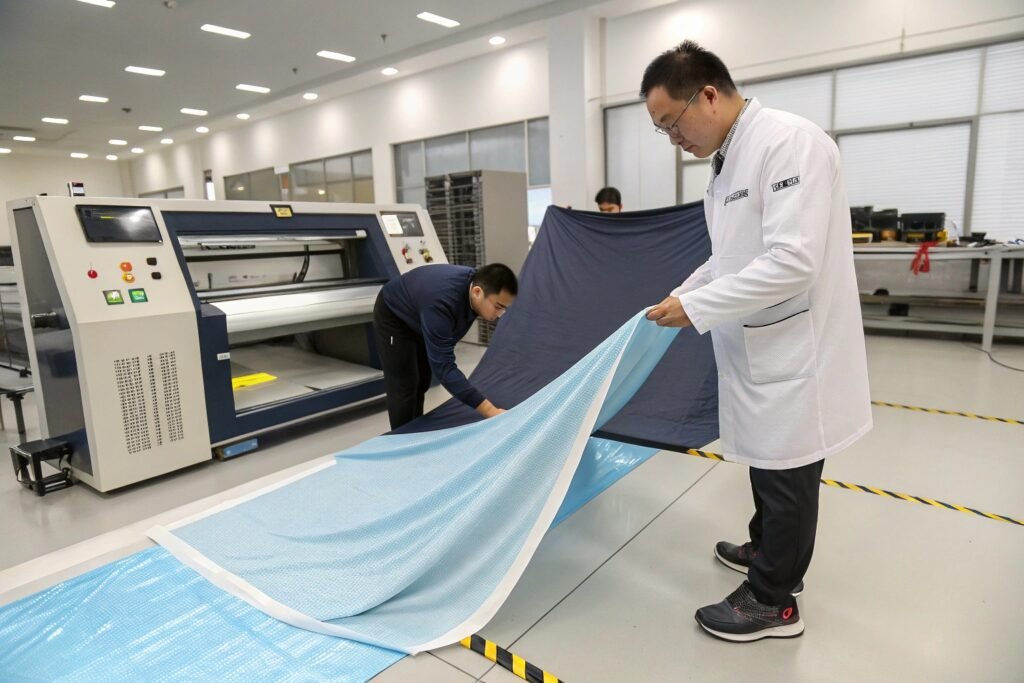

Third-party certification and QR-based traceability systems are strengthening trust in recycled nylon sourcing. At Fumao, we embed data chips and QR codes into rolls, allowing buyers to access origin, composition, dye batch, and QC logs instantly.

Why Is GRS Certification So Important?

The Global Recycled Standard (GRS) is the gold standard for confirming recycled content, chemical safety, and social compliance. Our recycled nylon swimwear lines are fully GRS-certified, enabling clients to confidently label their end products.

GRS adds value for buyers targeting eco-aware markets like Scandinavia or California. It also helps during audits and listings on Amazon Climate Pledge Friendly programs.

How Does Tech-Driven Traceability Work?

Buyers can scan a QR code system embedded on packaging to view compliance data. Our dashboard displays test results, mill location, yarn batch numbers, and more. This data transparency builds buyer trust, helping differentiate your line from competitors using unverified “recycled” claims.

Is There a Pricing Advantage or Risk in Choosing Recycled?

One of the biggest myths is that recycled fabrics are too expensive. In fact, with the right sourcing strategy, the cost gap is shrinking—and in some cases, recycled nylon is the smarter economic choice.

Recycled nylon offers tariff, logistics, and price stability advantages that offset initial per-unit cost differences. At scale, it becomes both an eco and economic win.

Can Recycled Nylon Help Avoid Tariff Penalties?

In certain cases, yes. US buyers sourcing from free-trade aligned Chinese zones or certified eco-lines can reduce exposure to tariffs on petrochemical-based imports. Our recycled nylon often qualifies for preferential treatment under USMCA green initiatives or EU-Vietnam/ASEAN textile pacts.

Freight classification codes (HS Codes) for recycled textiles may also differ slightly, giving some buyers flexibility in customs declarations—always consult with a customs broker to explore this.

How Do Minimums and Bulk Pricing Compare?

With factories like ours that maintain real-time inventory and flexible minimums, recycled nylon pricing becomes highly competitive. We offer MOQ as low as 300 meters for custom colors, and maintain bulk capacity that ensures lower per-meter costs on orders above 5,000 meters.

Plus, you gain marketing leverage with sustainable sourcing—boosting both brand value and retail margins.

Conclusion

The surge in recycled nylon’s popularity within the swimwear world isn’t accidental—it’s a response to real market needs. Brands want performance without guilt. Buyers want verified sourcing and cost efficiency. And consumers want to wear their values. At Fumao, we’ve seen this shift firsthand across the U.S., Europe, and Southeast Asia. With robust R&D, integrated QC, and digital supply chain tools, we’re proud to co-create the next wave of sustainable swimwear materials with our global partners.