When most people imagine sun protection, they think of sunscreen, sunglasses, or wide-brimmed hats. But clothing itself can act as a first line of defense against ultraviolet (UV) rays, which are responsible for sunburn, premature aging, and long-term risks such as skin cancer. In fact, the Skin Cancer Foundation notes that clothing is one of the most effective forms of sun protection because it does not wear off like sunscreen.

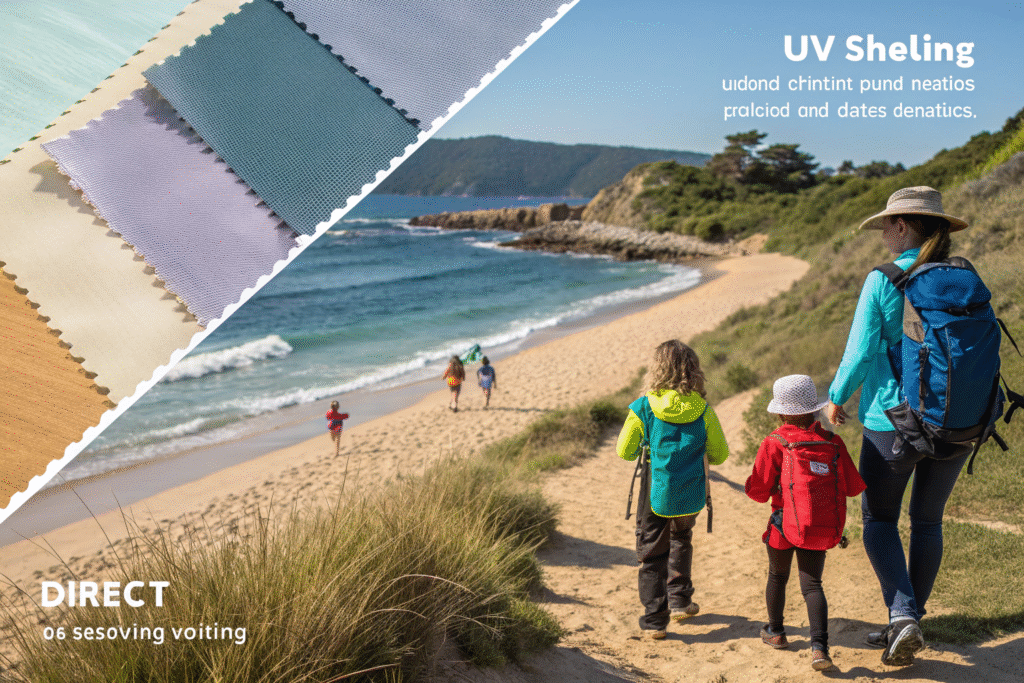

UV-protection fabrics are specially designed textiles that either block or absorb UV radiation. Their effectiveness is expressed in terms of UPF (Ultraviolet Protection Factor), a rating system that tells you how much UV radiation can pass through the fabric and reach the skin. For buyers and apparel brands, this knowledge is not just technical—it directly affects consumer health, product positioning, and compliance with global regulations.

What Factors Make a Fabric UV-Protective?

Not every fabric protects equally. A thin white cotton T-shirt may only provide UPF 5, allowing about 20% of UV rays to reach the skin, while a specially engineered polyester shirt can achieve UPF 50+, blocking 98% of UV radiation. Four main factors determine UV protection:

Fiber Type

Synthetic fibers like polyester and nylon absorb UV rays more effectively than natural fibers like cotton, silk, or linen. That’s why most high-performance swimwear and sports apparel is made from synthetics. Some modern textiles embed ceramic particles or UV-blocking chemicals into the fibers during extrusion, creating permanent protection. For example, Italian mill Carvico produces swimwear fabrics infused with titanium dioxide, achieving UPF 50+ that remains after hundreds of hours in chlorinated pools.

Weave Density

The tighter the weave, the less UV light passes through. A tightly woven denim jacket blocks almost all UV rays, while a loose muslin blouse may let in a significant amount of sunlight. A simple test is to hold the fabric up to the light—if you can see through it, UV can penetrate it as well.

Color and Dye

Dark colors such as navy, black, or red usually absorb more UV than whites or pastels. In one test by the American Association of Textile Chemists and Colorists (AATCC), a navy-blue polyester T-shirt rated UPF 40, while its identical white version only rated UPF 10. However, chemical dyes can enhance UV protection even in lighter shades, especially when combined with finishing treatments.

Finishes and Treatments

Fabrics can be treated with UV-absorbing compounds like titanium dioxide or zinc oxide, which are also common in mineral sunscreens. These finishes increase UPF ratings significantly without altering fabric weight or breathability. Outdoor brands such as Columbia Sportswear use patented "Omni-Shade" finishes that maintain UPF protection even after 40 machine washes.

Do Darker Fabrics Always Mean Better Protection?

In most cases, yes, but not always. A dark cotton T-shirt may provide more protection than a white one, but it also traps heat, making it less comfortable in summer. On the other hand, a light-colored polyester shirt treated with titanium dioxide can deliver UPF 50+ while staying cool and breathable. This demonstrates why fiber choice and treatments matter as much as color.

Can Regular Clothes Protect Without Treatment?

Yes, but protection varies. For example, a denim jacket naturally achieves UPF 100, making it nearly impervious to UV. But a thin cotton summer dress may only provide UPF 5–7, which is insufficient for prolonged sun exposure. That is why clothing marketed as “UV-protective” is tested and certified—it gives buyers and consumers confidence in its reliability.

How Is UV Protection Measured?

The effectiveness of UV-protective fabrics is expressed as UPF (Ultraviolet Protection Factor), which measures how much UV radiation a fabric allows to pass through to the skin.

UPF Rating System

- UPF 15–24: Good protection, blocks 93–95% of UV rays.

- UPF 25–39: Very good protection, blocks 96–97% of UV rays.

- UPF 40–50+: Excellent protection, blocks at least 98% of UV rays.

For comparison, a typical white cotton T-shirt may only provide UPF 5, meaning it blocks just 80% of UV rays. That’s why clothing specifically designed for sun protection is so important.

Why Is UPF More Reliable Than SPF for Clothing?

SPF (Sun Protection Factor) applies to sunscreen and only measures UVB rays, which cause sunburn. UPF, however, measures both UVA (aging, skin damage) and UVB (burning), making it a far more comprehensive indicator for textiles.

What Does “UPF 50+” Really Mean?

It means that only 1/50th (about 2%) of UV radiation can pass through the fabric. In practice, if you spend an hour in direct sun while wearing a UPF 50+ shirt, your skin receives the equivalent of just 72 seconds of sun exposure compared to being unprotected.

International Testing Standards for UV Fabrics

Different regions use standardized methods to ensure UV-protective claims are accurate and consistent.

AATCC 183 (United States)

This American test method measures how much UV light passes through a fabric swatch in both dry and wet states. It is the basis for UPF labeling in the U.S.

AS/NZS 4399 (Australia/New Zealand)

Australia has some of the world’s strictest sun safety standards due to its high UV index. This test requires garments to maintain UPF ratings even when stretched or wet, simulating real-world conditions like swimming or sweating.

EN 13758 (Europe)

The European standard not only sets UPF test requirements but also governs labeling, ensuring clothing provides enough body coverage, not just protective fabric.

ISO 105-B02 and Related Standards

These standards check whether UV protection degrades after washing or sunlight exposure, ensuring fabrics remain protective over their entire lifespan.

Do All Fabrics Claiming UV Protection Meet Standards?

No. A 2022 market analysis found that nearly 30% of garments labeled “UV-protective” on global e-commerce platforms lacked certified lab documentation. Some products tested below UPF 15, despite being marketed as UPF 50+. Buyers should always request reports from trusted labs like SGS or Intertek.

Why Do Australian Standards Require Wet Testing?

Because fabrics can lose significant UV protection when saturated with water. For example, a polyester shirt rated UPF 30 when dry may drop to UPF 10 when wet. The AS/NZS 4399 standard ensures garments still perform under real outdoor conditions.

Why UV-Protective Fabrics Matter for Buyers

UV-protective fabrics are not just a trend—they are a fast-growing category with practical benefits across industries.

- Outdoor Sports & Athleisure: Lightweight polyester and nylon fabrics with UPF 50+ ratings are essential for running, hiking, cycling, and swimming. For example, brands like Patagonia and Columbia have integrated UV-protection into their summer gear.

- Children’s Clothing: Kids’ skin is thinner and more vulnerable, making certified UPF swimwear and playwear a must-have in Western markets. Sales of kids’ UV-protective swimwear have doubled in Europe between 2018–2022.

- Workwear Applications: Construction and agricultural workers exposed to the sun daily are at high risk. Certified UV clothing not only protects them but also helps employers comply with occupational safety regulations.

- Fashion Integration: Modern UV-protective fabrics are indistinguishable from regular textiles, allowing designers to create stylish dresses, shirts, and trousers that carry hidden protective benefits.

Is UV Protection a Selling Point in Global Markets?

Yes. The UV-protective clothing market is projected to reach USD 1.5 billion by 2028, growing at a CAGR of 6.5%, driven by consumer health awareness and stricter safety regulations in Europe, North America, and Australia.

How Can Brands Differentiate With UV Fabrics?

By combining UV protection with other functions such as moisture-wicking, stretch, or antibacterial finishes. Multi-functional textiles have stronger consumer appeal and justify premium pricing. For example, Nike markets apparel that combines UPF 50+ sun protection with sweat-wicking and odor-control finishes.

Conclusion

UV-protection fabrics represent the next evolution in performance and everyday clothing. They rely on fiber choice, weave density, color, and protective treatments to shield against harmful rays. More importantly, their effectiveness is certified through rigorous global standards such as AATCC 183, AS/NZS 4399, and EN 13758.

For buyers, the key is to demand certified UPF test results, understand how fabrics behave when wet or stretched, and source from reliable manufacturers. With rising global awareness of sun safety, offering UV-protective fabrics allows your brand to stand out, attract health-conscious consumers, and build long-term trust.

At Shanghai Fumao, we specialize in producing and sourcing certified UV-protection textiles with proven durability, fast sampling, and worldwide delivery. If you are ready to develop your next sun-safe collection, reach out to our Business Director Elaine at elaine@fumaoclothing.com to discuss your sourcing needs.