Tricot fabric. If you're in the apparel industry, especially in intimate wear or activewear, you've likely heard this term. But what exactly is it? And why does it consistently dominate the lingerie market? As a fabric supplier with over two decades in the heart of China's textile hub, Keqiao, we get these questions daily from buyers like you who are keen on understanding the materials that make their products successful. This isn't just academic; it's about making smarter, more profitable sourcing decisions.

Simply put, tricot is a specific type of warp-knit fabric known for its smooth texture, minimal stretch, and exceptional durability. Its popularity in lingerie stems from a unique combination of comfort, shape retention, and a luxurious feel against the skin. Unlike other knits, tricot offers a consistency that designers and manufacturers rely on for garments that need to look and feel flawless. For global buyers, understanding tricot is key to navigating the complexities of sourcing high-quality intimate apparel.

In this article, we will dive deep into the world of tricot fabric. We'll break down its technical makeup, explore the reasons for its stronghold in lingerie, compare it to other common fabrics, and provide a practical guide for sourcing it effectively. By the end, you'll have a comprehensive understanding of why tricot remains a top choice and how you can leverage its properties for your next collection.

What are the defining characteristics of tricot fabric?

When you run your hand over a piece of tricot, you immediately notice its signature smoothness. This isn't by accident. As a warp knit, tricot is constructed with yarns looping vertically along the length of the fabric. This manufacturing process is fundamentally different from the more common weft knitting, where a single yarn travels horizontally. This structural difference is the source of tricot's key properties.

The most defining characteristic of tricot is its dimensional stability. This means it doesn't curl at the edges like many other knits, such as jersey, and it has minimal stretch in the lengthwise direction, with a slight give in the width. This stability is a game-changer for manufacturing. It allows for cleaner cutting and sewing, reducing fabric waste and improving production efficiency. For items like lingerie straps or bra cups that require precise shape retention, this property is non-negotiable. Furthermore, tricot is renowned for its resistance to runs and snags. The interlooped warp yarns create a resilient structure that is less likely to be damaged during production or wear.

How is tricot fabric made?

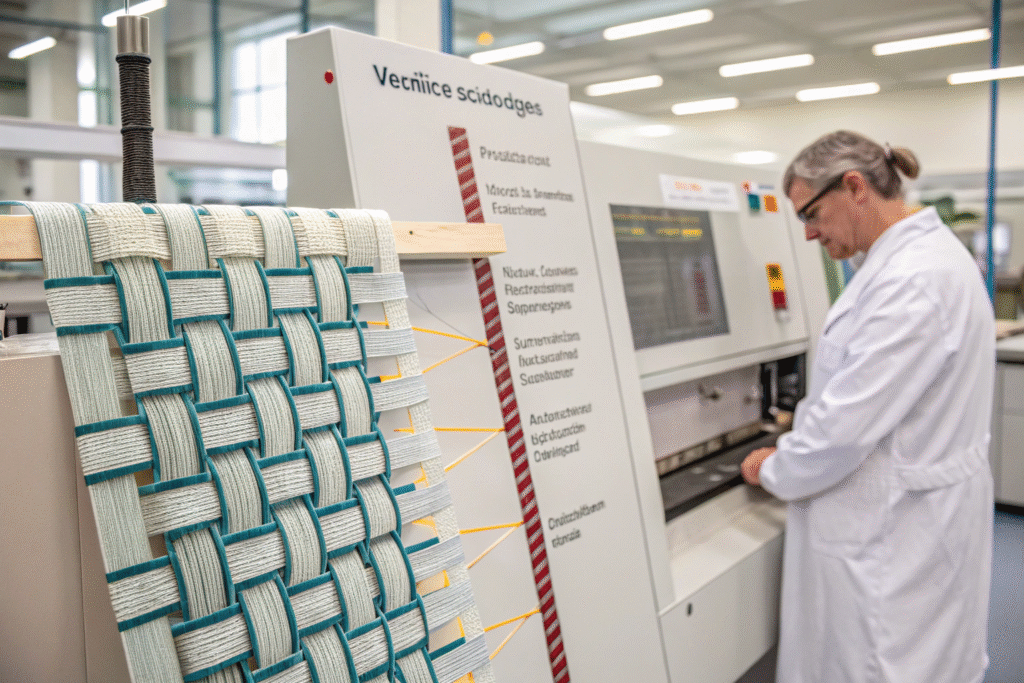

The production of tricot fabric is a marvel of textile engineering. It is created on sophisticated tricot knitting machines, which are equipped with multiple guide bars and thousands of needles. Each guide bar controls a set of warp yarns, and by programming the movement of these bars, manufacturers can create a vast array of patterns and textures. The yarns are fed simultaneously from beams, much like in weaving, but they are looped together to form the fabric. This high-speed process results in fabric that is typically produced in wide rolls, making it highly efficient for large-scale production runs. The versatility of these machines allows us at Fumao Textiles to produce everything from simple, plain tricot to more complex meshes and jacquard designs, all with the same base level of quality and stability.

What are the common fiber blends used in tricot?

While the construction defines tricot, the fiber content defines its performance and feel. The most common fiber used is polyester. Polyester tricot is strong, durable, and has excellent moisture-wicking properties, making it a staple for athletic wear and everyday lingerie. Nylon is another popular choice, prized for its exceptional softness, brilliant dyeability, and smooth hand feel, which is why it's often the go-to for premium lingerie. For enhanced comfort and breathability, blends are king. A polyester-spandex blend combines durability with essential stretch, ideal for activewear and shapewear. Similarly, nylon-spandex tricot offers a luxurious, stretchy feel perfect for comfortable, form-fitting lingerie. At our R&D lab, we constantly experiment with new blends, including recycled polyester and organic materials, to meet the growing demand for sustainable options without compromising on performance.

Why is tricot the preferred choice for lingerie manufacturing?

The marriage between tricot fabric and lingerie is a textbook example of material perfectly suited to application. The requirements for lingerie are exceptionally high: it must be comfortable for all-day wear, durable enough to withstand repeated washing, aesthetically pleasing, and capable of maintaining its shape under tension. Tricot checks every single box. Its smooth, often silky surface feels gentle against sensitive skin, eliminating irritation. This comfort factor is paramount for a product category worn directly against the body.

From a production standpoint, tricot's stability is a major advantage. When cutting delicate lace and multiple layers for bras and panties, fabric that doesn't curl or distort simplifies the process immensely, leading to higher yield and fewer defects. The fabric's excellent dye affinity ensures vibrant, consistent colors that last, which is crucial for the fashion-driven lingerie market. Moreover, tricot provides the perfect base for incorporating elastic materials like spandex, giving garments the necessary stretch and recovery to flatter the body without losing their form. This combination of comfort, durability, and manufacturing efficiency makes tricot an unbeatable choice for both mass-market and luxury lingerie brands.

How does tricot enhance comfort and fit in lingerie?

Comfort in lingerie is achieved through a lack of friction and adaptable fit. Tricot's seamless-like surface reduces chafing, while its controlled stretch allows it to move with the body. For example, in bra linings and back panels, tricot provides a supportive yet forgiving structure. It molds to the body's contours without binding or digging in. The breathability of certain tricot blends, especially those with natural fiber mixes, also plays a key role in maintaining comfort by allowing air circulation and moisture vapor to escape, keeping the wearer dry and comfortable throughout the day.

What are the functional benefits for manufacturers?

For manufacturers, the benefits are tangible and directly impact the bottom line. The dimensional stability of tricot leads to higher cutting efficiency, meaning less fabric is wasted due to distortion. Its strength reduces the risk of tearing during the sewing process. Furthermore, tricot is less prone to curling, which speeds up assembly and improves the overall quality of the finished garment. These factors contribute to a faster production cycle and lower costs per unit. Our partnership with dyeing and finishing factories ensures that the tricot we supply has consistent colorfastness and shrinkage control, which are critical for maintaining size specifications and quality standards across large orders.

How does tricot compare to other knit fabrics like jersey?

Understanding the differences between tricot and other knits is essential for making the right sourcing choice. While both are knit fabrics, their behavior and best uses are distinct. Let's take the common jersey knit as a primary example. Jersey is a weft knit, the same type used in most T-shirts. Its most noticeable difference is its significant stretch in the widthwise direction and a tendency to curl heavily at the edges when cut. This makes it more challenging to work with for structured garments.

The table below provides a quick comparison:

| Feature | Tricot Fabric (Warp Knit) | Jersey Fabric (Weft Knit) |

|---|---|---|

| Stretch | Minimal lengthwise, slight widthwise | Significant widthwise, minimal lengthwise |

| Edge Curling | Very resistant to curling | Prone to heavy curling |

| Durability | High; resistant to runs and snags | Lower; can snag and run easily |

| Drape | Smooth, fluid drape | Soft, casual drape |

| Common Uses | Lingerie, activewear, linings, uniforms | T-shirts, dresses, casual apparel |

As you can see, tricot's stability and durability make it superior for applications where shape retention and longevity are critical. Jersey, on the other hand, offers a softer, more casual drape ideal for comfortable everyday wear but lacks the structural integrity needed for precision garments like bras.

What are the advantages of tricot over jersey?

The advantages of tricot become clear in technical applications. Its resistance to curling is a massive advantage in manufacturing, saving time and reducing fabric waste. Its strength means garments made from tricot will have a longer lifespan, enduring repeated washing and wear without pilling or losing shape. For lingerie and activewear, this durability is a key selling point for consumers. While jersey might be cheaper initially, the total cost of ownership for a tricot garment can be lower due to its longevity and easier production handling.

When should you choose jersey over tricot?

The choice isn't about which fabric is better, but which is more appropriate for the product. Jersey knit is the undisputed champion for casual, comfortable apparel. Its soft hand feel and significant stretch make it ideal for T-shirts, loungewear, and casual dresses where a relaxed fit is desired. If your design prioritizes a soft, cozy, and stretchy feel over precise structure and durability, then jersey is the more cost-effective and suitable choice. It's all about aligning the fabric properties with the intended function and aesthetic of the final garment.

What should buyers consider when sourcing tricot fabric from Asia?

Sourcing tricot fabric from Asia, particularly from a textile hub like Keqiao, China, offers significant advantages in cost, quality, and innovation. However, to ensure a successful partnership, buyers must be strategic. The first and most critical step is to verify the supplier's expertise and capabilities. Not all fabric mills are created equal. You need a partner who understands the nuances of tricot production, from the base yarn selection to the dyeing and finishing processes. Ask potential suppliers about their experience with the specific fiber blends and weights you require for your lingerie line.

Secondly, insist on transparency and quality assurance. Reputable suppliers will have no issue providing quality certifications and detailed technical data sheets for their fabrics. These documents should cover essential parameters like composition, weight, stretch and recovery, colorfastness, and shrinkage rates. At Fumao, our CNAS-accredited lab tests every batch, and we provide QR codes that give you instant access to this data. This level of transparency is your best defense against substandard materials. Finally, consider the entire supply chain. How agile is the supplier in producing samples? What are their lead times for bulk production? Can they handle logistics and customs clearance efficiently? Partnering with a full-service provider who manages the process from yarn to shipment mitigates risk and simplifies your operations.

How to ensure consistent quality and certification?

Consistency is the hallmark of a reliable supplier. When sourcing tricot, especially for markets like the EU and US, ensure the fabrics meet international standards such as OEKO-TEX® Standard 100 or REACH compliance, which verify the absence of harmful substances. Work with a supplier who has a robust Quality Control system in place. This includes pre-production checks on raw materials, in-process inspections during knitting and dyeing, and a final random inspection before shipment. Ask for their standard inspection protocol and pass/fail rates. A professional QC team, like ours, will conduct fabric inspections for defects like dye spots, holes, or uneven tension, ensuring you receive a uniform product every time.

What are the logistics and cost considerations?

Understanding the total landed cost is crucial. While the fabric price per meter is important, it's just one part of the equation. You must factor in shipping costs, import tariffs, and insurance. For U.S.-bound shipments, it's essential to work with a supplier who has experience in classifying products correctly to avoid customs delays. Given the current geopolitical climate, some buyers are exploring tariff mitigation strategies, such as using our partners in Southeast Asia for certain finishing steps. Furthermore, inquire about the supplier's packaging methods—proper packaging prevents damage during transit—and their flexibility in shipping options (e.g., by sea for large orders or by air for urgent samples). A supplier with strong financial stability can offer secure payment terms and ensure your production cash flow remains uninterrupted.

Conclusion

Tricot fabric's reign in the lingerie industry is well-earned. Its unique combination of smooth comfort, exceptional durability, and manufacturing-friendly stability makes it an indispensable material for creating intimate apparel that looks and feels premium. From understanding its warp-knit structure to recognizing its advantages over other knits like jersey, a deep knowledge of tricot empowers you to make smarter, more informed sourcing decisions. The key to success lies in partnering with a supplier who not only provides high-quality tricot but also offers the technical expertise, rigorous quality control, and seamless logistics support required in today's competitive market.

If you are looking to develop a new lingerie line or refresh your existing collection with high-quality, reliable tricot fabrics, we invite you to experience the Fumao difference. Our integrated supply chain from weaving to finishing allows us to control every aspect of quality and delivery. Contact our Business Director, Elaine, today at elaine@fumaoclothing.com to discuss your specific needs and request complimentary fabric swatches. Let us help you weave your next success story.