Many of my clients, especially those designing luxury apparel or high-end home furnishings, ask me this question. They come to us seeking the perfect fabric that balances shine, drape, and durability. The confusion is understandable. Both fabrics are known for their glossy surface and smooth feel, but the difference is crucial for your project's success. Choosing the wrong one can impact the look, feel, and cost of your final product.

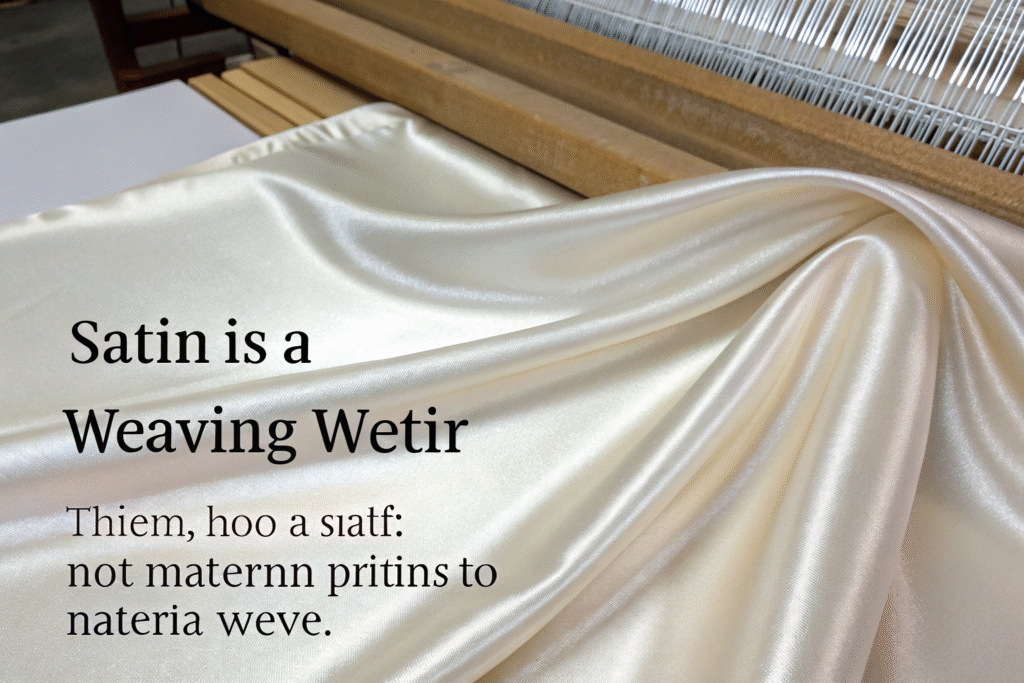

The key difference lies in the material itself. Silk charmeuse is a specific type of fabric defined by its fiber content (silk) and its weave (satin). Satin, however, is a weaving technique that can be applied to various fibers, including silk, polyester, and nylon. So, all silk charmeuse is a form of satin, but not all satin is silk charmeuse. This fundamental distinction affects everything from price and performance to care and sustainability. Understanding these details will empower you to make the best decision for your brand.

Let's unravel the details to ensure your next collection features the right fabric for breathtaking results.

What is silk charmeuse fabric made of?

When you choose silk charmeuse, you are selecting a natural fiber known for its unparalleled quality. The term "charmeuse" actually refers to the weave, but in the textile industry, it has become synonymous with silk fabric made with this specific method. The magic of silk charmeuse begins with the silkworm, producing a continuous protein filament that is woven in a particular way to create its signature characteristics.

Silk charmeuse is defined by two elements: its raw material and its construction. The fiber is mulberry silk, renowned for its long, smooth filaments. The construction is the satin weave. This weave uses a technique where the warp yarns "float" over multiple weft yarns. In charmeuse, these floats are longer than in standard satin, creating more surface area for light to reflect. This results in that incredible, deep luster on the fabric's face and a soft, dull back. Our clients in the luxury market value this because it is a natural fiber with a unique biochemistry that offers breathability and a luxurious hand-feel that is difficult to replicate.

How does the production of silk charmeuse affect its price?

The production process of silk charmeuse is labor-intensive and costly, which is directly reflected in its price. It starts with sericulture, the farming of silkworms. This is an intricate process that requires careful handling to harvest the long, continuous filaments from the cocoons. These filaments are then spun into yarns. The weaving process itself requires precision. The long floats in the charmeuse weave make the fabric more delicate to handle on high-speed looms, demanding expertise to prevent snags. Furthermore, finishing processes like degumming and dyeing must be meticulously controlled to preserve the silk's natural beauty and sheen. This entire supply chain, from farm to fabric, contributes to the premium cost. For brands focused on sustainable fashion, the natural and biodegradable properties of silk are a key selling point, but they come at a higher initial cost compared to man-made alternatives.

What are the main characteristics and uses of silk charmeuse?

The main characteristics of silk charmeuse are its high luster, fluid drape, and smooth, tactile feel. It is a lightweight fabric with a beautiful, heavy fall that makes it ideal for flowing garments. Its glossy front provides a luxurious appearance, while its matte back offers a comfortable feel against the skin. However, these same qualities present challenges. The long floats make the fabric prone to snagging, and it can be weakened by prolonged exposure to sunlight. It also requires dry cleaning or very gentle hand washing. Because of this, its primary uses are in high-end applications where beauty and drape are prioritized over durability. You will find it in luxury evening gowns, lingerie, linings for premium jackets, and elegant home textiles like pillowcases and sheets, where its smooth surface is beneficial for hair and skin.

What is the satin weave technique?

Satin is not a material; it is a weaving method. This is the most important concept to grasp. The satin weave is one of the three fundamental textile weaves, alongside plain and twill. Its primary goal is to create a fabric with a maximum amount of luster and a smooth hand feel. This is achieved through a specific interlacing pattern that minimizes the number of interlacings between the warp and weft yarns.

In a satin weave, the warp yarns dominate the surface of the fabric. They "float" over several weft yarns before passing under one. This long float allows light to reflect consistently off the unbroken surface of the yarns, producing the characteristic shine. The fewer the interlacings, the brighter the shine. However, these long floats also make the weave inherently less durable than a plain or twill weave, as they can be easily snagged. The versatility of the satin weave is its greatest strength. It can be applied to almost any fiber. When made with polyester yarns, it creates an affordable, durable, and brightly shiny fabric. When made with silk, it becomes charmeuse or silk satin. When made with cotton, it creates sateen, which has a soft, subtle luster.

What types of fibers are used to make satin fabric?

A wide array of fibers can be woven using the satin technique. The choice of fiber dramatically alters the fabric's properties, cost, and end-use. The most common fibers include:

- Synthetic Fibers: Polyester and nylon are the most popular. They are inexpensive, strong, wrinkle-resistant, and can be engineered to produce a very high shine. This makes them ideal for mass-market fashion, academic gowns, and dance costumes.

- Semi-Synthetic/Rayon Fibers: Viscose, acetate, and cupro are often used. They offer a more luxurious, silk-like drape and feel than polyester at a moderate price point. They are common in linings and more affordable evening wear.

- Natural Fibers: Silk is the premium option, as discussed. Cotton can be woven in a satin weave to create sateen, which is valued for its softness and subtle sheen in bedding and dresses.

This table summarizes how the fiber choice impacts the final satin fabric:

| Fiber Type | Typical Use | Key Properties |

|---|---|---|

| Polyester | Mass-market apparel, decorations | High durability, low cost, easy care, less breathable |

| Silk | Luxury fashion, lingerie | Premium feel, excellent drape, biodegradable, requires delicate care |

| Acetate | Linings, costume design | Silky appearance, good drape, moderate cost |

| Cotton (Sateen) | Bedding, shirts | Soft, absorbent, subtle luster, more durable than silk satin |

How does the durability of satin compare to other weaves?

The durability of a satin-weave fabric is generally lower than that of plain or twill weaves but varies significantly with the fiber used. The long floats that create the shine are also the fabric's weakness, as they are exposed and susceptible to abrasion and snagging. A plain weave, where warp and weft yarns alternate over and under each other (like in canvas or chiffon), has the highest number of interlacings, making it very strong and stable. A twill weave (like in denim or gabardine) has a diagonal rib pattern that offers a good balance of durability, drape, and resistance to wrinkles. Therefore, a polyester satin will be more durable than a silk charmeuse simply because the polyester fiber itself is stronger and more resistant to abrasion, even though both share the same vulnerable weave structure.

Silk Charmeuse vs. Satin: A direct comparison for designers.

For you as a designer or buyer, the choice between silk charmeuse and other satins boils down to the priorities for your specific product. Are you creating a heirloom-quality evening gown where drape and natural luxury are paramount? Or are you producing a line of durable, colorful dance costumes that need to withstand frequent wear and washing? The decision matrix is clear when you compare them side-by-side.

Let's put them head-to-head. Silk charmeuse offers an unmatched, rich luster and a fluid, heavy drape that gives garments an elegant movement. It is highly breathable and hypoallergenic, making it comfortable against the skin. Its major drawbacks are its high cost, delicate nature, and sensitivity to sunlight and moisture. In contrast, a satin made from polyester or nylon offers a brighter, sometimes more plastic-like shine. Its drape is good but often stiffer than silk. The huge advantages of synthetic satin are its low cost, high durability, resistance to wrinkles, and ease of care—it is often machine washable. This makes it a practical choice for applications where luxury is secondary to function and budget.

When should you choose silk charmeuse for your project?

You should choose silk charmeuse when your project demands the highest levels of luxury, prestige, and performance from a natural fiber. It is the ideal choice for:

- High-End Fashion: Designer evening wear, wedding dresses, and luxury lingerie where the sensory experience (hand-feel) and elegant drape are critical.

- Special Occasion Garments: Items where the "wow" factor of a deep, natural luster is a key selling point.

- Skin-Sensitive Applications: Because of its natural protein structure, it is excellent for pillowcases and linings in premium clothing, often marketed as beneficial for skin and hair.

If your brand identity is built on sustainable and natural materials, and your target consumer values biodegradability and natural origins, then silk charmeuse is the unequivocal choice. The higher cost is justified by the premium market positioning and the unparalleled quality it delivers.

When is a synthetic satin a better option?

A synthetic satin, like polyester satin, is a better option when your priorities are budget, durability, and easy maintenance. It is the practical choice for:

- Mass-Market Production: Fast fashion items, costumes, and accessories where cost-effectiveness is essential.

- High-Abrasion Applications: Dance costumes, uniforms, cheerleading outfits, and decorative items that require frequent wear and washing.

- Projects Requiring Color Fastness: Synthetic satins can be dyed in very vibrant, colorfast hues that are more resistant to fading than silk.

- Items with Structured Designs: If the garment requires more body and less fluid drape, the inherent stiffness of polyester satin can be an advantage.

For businesses looking to optimize their supply chain management, synthetic satins offer greater consistency, availability, and lower risk of damage during production and shipping, making them a reliable and efficient choice for large orders.

How to source the right fabric for your brand.

Sourcing the correct fabric is the final, critical step. At our company, we guide clients like you through this decision every day. It's not just about technical specifications; it's about aligning the fabric with your brand's vision, budget, and operational capabilities. We provide samples and expert advice to ensure you see and feel the difference before you commit to a large order.

The first step is always to request physical swatches. Looking at a digital image is not enough. You need to feel the weight, test the drape on a mannequin, and examine the luster under different lighting conditions. For silk charmeuse, ask about the momme weight—a higher momme indicates a heavier, more durable silk. For satin, confirm the fiber content percentage and the finishing processes, such as calendaring, which can enhance the shine. It is also crucial to discuss lead times and minimum order quantities (MOQs). Silk charmeuse, being a natural product, may have longer production lead times than synthetic satins, which can be produced continuously.

What questions should you ask your fabric supplier?

To avoid costly mistakes, you should ask your supplier specific, detailed questions. This demonstrates your expertise and ensures you get exactly what you need. Key questions include:

- "Can you provide a detailed specification sheet?" This should include fiber content, weight (in GSM or momme), width, and construction details.

- "What certifications do you have?" For silk, look for Oeko-Tex Standard 100 or GOTS certification to ensure it's free from harmful chemicals. For synthetics, ask about recycled content (e.g., Global Recycled Standard).

- "What is your testing protocol?" Inquire about tests for colorfastness to washing and light, shrinkage rates, and seam slippage. A reputable supplier like us will have a CNAS-accredited lab to provide these reports.

- "What are the logistics and payment terms?" Understand shipping options, timelines, and Incoterms to accurately calculate landed cost.

Why is partnering with an expert supplier crucial for quality?

Partnering with an expert supplier is crucial because they become an extension of your quality control team. A supplier with deep experience, like ours in the Keqiao textile cluster, can anticipate problems before they occur. We understand how different dyes behave on silk versus polyester, and we can recommend the right finishing treatments to achieve the desired hand-feel and performance. We manage the entire process from yarn sourcing to final inspection, ensuring consistency across every meter of fabric. This end-to-end control is what guarantees that the beautiful sample you approved is exactly what arrives in your warehouse, saving you from the headaches of inconsistent quality and production delays.

Conclusion

In summary, the journey from confusion to clarity between silk charmeuse and satin is all about understanding that one is a specific natural fiber product, while the other is a versatile weaving technique. Silk charmeuse offers an unparalleled, luxurious experience rooted in nature, ideal for high-end, sensitive applications. Satin weaves, applicable to many fibers, provide practical, durable, and cost-effective solutions for a wider range of products. Your choice ultimately shapes the identity, cost, and performance of your final design.

Making the right fabric choice is the foundation of a successful garment. It impacts everything from design and manufacturing to marketing and customer satisfaction. With the right partner, you can navigate these choices confidently. If you are ready to source high-quality silk charmeuse, polyester satin, or any other fabric for your next collection, we are here to provide not just materials, but solutions. Let's discuss your specific needs and bring your vision to life with the perfect fabric.

For a personalized consultation and to request fabric swatches, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. We look forward to helping you weave your success story.