When fabric buyers or product developers are choosing textiles for their collections, two synthetic fibers often dominate the discussion: nylon and polyester. At first touch, they can feel very similar—smooth, durable, and versatile. Both are widely used in apparel, outdoor gear, and industrial applications. However, the details reveal important differences that determine whether nylon or polyester is better for a particular use. These differences matter for fashion brands, sportswear designers, and manufacturers in industries as diverse as automotive and construction.

In short: Nylon is stronger, stretchier, and softer, while polyester is cheaper, more UV-resistant, and far better at repelling water. Each fiber brings distinct strengths and weaknesses that directly influence cost, performance, and consumer satisfaction.

Fiber Origins: How Are Nylon and Polyester Made?

Nylon and polyester share a common source—petroleum—but they come from different chemical families.

- Nylon was invented by DuPont scientists in 1935 as the world’s first fully synthetic fiber. Marketed as a replacement for silk, it was quickly used for women’s stockings and parachutes during World War II. It is a polyamide, created by polymerizing diamine and dicarboxylic acid, producing strong amide bonds that give nylon high tensile strength.

- Polyester was developed later, in the 1940s, by British chemists and commercialized globally. The most common type, PET (polyethylene terephthalate), is made by reacting terephthalic acid with ethylene glycol. Polyester is simpler and cheaper to synthesize at scale, which is why it became the backbone of the fast fashion and home textile industries.

According to industry reports, polyester accounts for about 52% of global fiber production today, while nylon makes up just 5–7%. Polyester’s dominance is tied to its lower cost and ease of mass production, while nylon remains a premium fiber for performance applications.

Why Was Nylon a Game-Changer in the 1930s?

Nylon was the first fiber that could rival silk’s softness while outperforming it in strength. During WWII, the U.S. military shifted from silk to nylon for parachutes and ropes because nylon resisted tearing under extreme stress. This transition helped establish nylon’s reputation as a “super fiber.”

Why Did Polyester Overtake Nylon in Popularity?

Because polyester was cheaper to produce and more resistant to weathering. By the 1970s, polyester had become the world’s most popular textile fiber, marketed in slogans like “Polyester: the fabric of the future.” Its ability to be blended with cotton and other fibers made it highly versatile for everyday clothing.

Strength and Durability: Which Is Tougher?

Both nylon and polyester are strong, but nylon has a slight edge in raw tensile strength and abrasion resistance.

- Nylon: Its molecular structure allows it to stretch 10–20% before breaking, giving it resilience against tearing. This makes it ideal for heavy-duty applications such as military gear, climbing ropes, airbags, and industrial conveyor belts. For instance, nylon climbing ropes can absorb shock loads without snapping, a critical safety feature in mountaineering.

- Polyester: While not as elastic, polyester maintains its shape better. It resists shrinking, wrinkling, and stretching, even after repeated washing. Polyester’s strength is more about dimensional stability, which is why it is often chosen for uniforms, home furnishings, and sports jerseys that must hold their form over time.

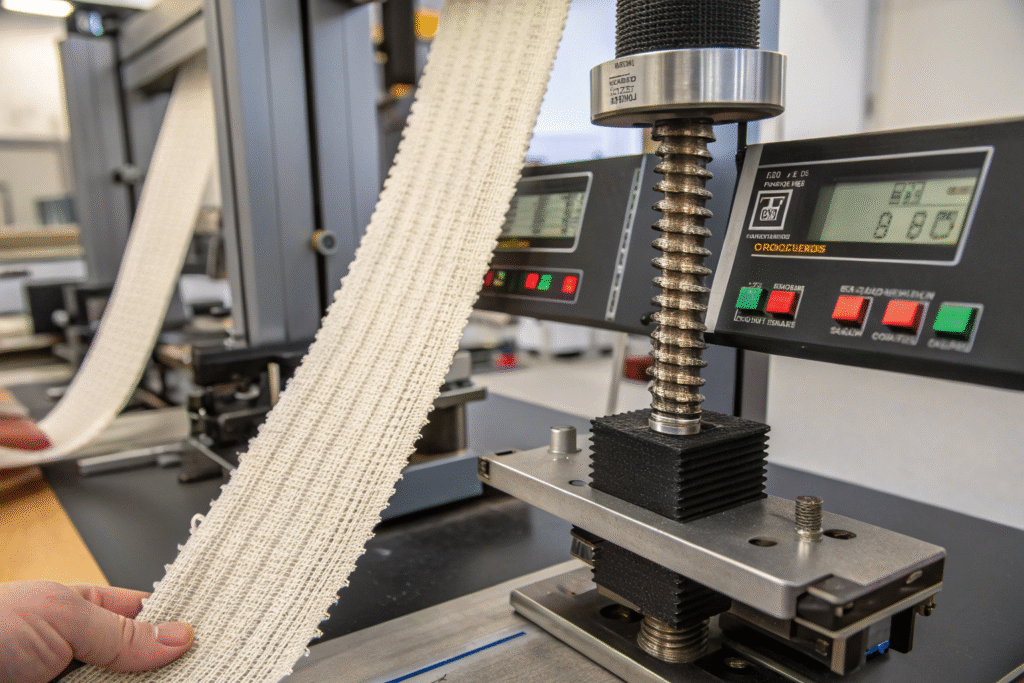

In abrasion tests conducted by textile research institutes, nylon fabrics lasted up to 25% longer under friction compared to polyester, but polyester retained 95% of its shape after 100 washing cycles, compared to nylon’s 80%.

Is Nylon Always Stronger Than Polyester?

Yes in terms of break strength, but not necessarily in long-term performance. A nylon backpack may handle heavy loads better, but a polyester one may resist fading, sagging, and distortion more effectively after years of use.

Which Lasts Longer in Outdoor Furniture?

Polyester. Its superior UV resistance allows patio cushions and awnings made from polyester to remain bright and strong for years, while nylon fabrics often yellow and weaken under direct sunlight after a single season.

Moisture and UV Resistance: How Do They Compare?

Moisture Resistance

- Nylon: Absorbs up to 10% of its weight in water. In humid or rainy conditions, nylon can become heavier and take hours to dry. A nylon T-shirt after a workout may cling uncomfortably to the body.

- Polyester: Absorbs less than 1% of water. It wicks moisture away and dries quickly, making it a go-to fiber for sportswear, running shirts, and outdoor jackets.

UV Resistance

- Nylon: Susceptible to UV degradation. Prolonged sun exposure causes yellowing, loss of strength, and brittleness. Nylon fishing nets, for example, weaken quickly in tropical sun without protective coatings.

- Polyester: Excellent UV stability. Polyester fabrics used for sails, flags, and outdoor signage remain intact and colorful even after months of exposure to harsh sunlight.

Why Do Swimwear Brands Still Use Nylon Despite Its Weak UV Resistance?

Because nylon’s stretch and softness provide the comfort and body-hugging fit that swimmers want. Many swimwear brands address nylon’s UV weakness by blending it with polyester or adding UV-blocking finishes.

Why Is Polyester Preferred for Outdoor Flags and Tents?

Because polyester combines quick-drying properties with UV stability, ensuring products retain their shape and vibrant colors after months of outdoor use.

Comfort and Texture: Which Feels Better?

- Nylon: Feels softer, smoother, and more luxurious, often compared to silk. It stretches slightly with the body, making it comfortable for lingerie, hosiery, yoga leggings, and performance gear.

- Polyester: Feels slightly stiffer but offers crispness and body. Modern microfiber polyester, however, can feel almost as soft as nylon, which is why it is now common in bedsheets and sports apparel.

Is Nylon Always More Comfortable?

Not always. In hot and humid weather, nylon’s tendency to absorb water can make it feel clammy. Polyester, being hydrophobic, feels drier and cooler, especially during workouts.

Can Polyester Be Made as Soft as Nylon?

Yes. Microfiber polyester is engineered to have finer fibers than silk, creating an ultra-soft feel. It is now widely used in premium bedding and activewear, rivaling nylon’s comfort at a lower cost.

Cost and Sustainability: Which Wins?

- Nylon: More expensive to produce because of its complex chemistry. Recycling is limited, but initiatives like ECONYL transform discarded fishing nets and carpets into regenerated nylon yarns, used by brands like Prada and Gucci.

- Polyester: Significantly cheaper and easier to produce. It is also widely recycled: rPET (recycled polyester) made from plastic bottles is now mainstream, accounting for more than 14% of global polyester output. Brands like Adidas aim to use 100% recycled polyester by 2030.

Why Is Polyester Considered More Sustainable Today?

Because of rPET’s scalability. Billions of plastic bottles are diverted from landfills and oceans each year and turned into polyester fibers. While nylon recycling exists, it remains smaller due to higher costs and processing complexity.

Is Nylon Worth Paying More For?

Yes, in high-performance contexts. A $200 nylon ski jacket may outperform a $100 polyester one in flexibility and durability, making the higher investment worthwhile for outdoor professionals and athletes.

Conclusion

Nylon and polyester may look alike at first glance, but their performance differences shape their uses in today’s textile market.

- Nylon is stronger, stretchier, and silkier, but more expensive, prone to UV damage, and slower to dry. It shines in performance and technical applications such as military textiles, luxury swimwear, and climbing gear.

- Polyester is cheaper, more UV-resistant, hydrophobic, and easier to recycle, making it the dominant fiber in global apparel and outdoor fabrics. Its future is tied to sustainability as rPET continues to grow.

For buyers, the decision often depends on balancing cost, durability, comfort, and sustainability.

At Shanghai Fumao, we supply both nylon and polyester fabrics with certified testing, high-volume capacity, and fast delivery. Whether you need nylon for strength and luxury performance or polyester for affordable, UV-stable, and sustainable collections, our team can help. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your next fabric sourcing project.