For generations, textile production faced limitations in pattern complexity. The jacquard loom's invention marked a transformative moment in textile manufacturing. This innovation enabled the creation of fabrics with elaborate, detailed patterns woven directly into the material's structure. Unlike surface printing techniques, jacquard patterns are integral to the fabric construction, providing distinctive depth and textural qualities that set them apart in the market.

Jacquard loom weaving represents a specialized textile production method utilizing programmable looms to create intricate, raised patterns directly within the fabric matrix. Jacquard fabric achieves premium status through its sophisticated manufacturing process, exceptional durability, rich textural properties, and high-end visual appeal, making it particularly valued in luxury fashion and interior design applications.

For businesses sourcing materials for their upcoming collections, understanding jacquard's distinctive qualities provides significant competitive advantage. This weaving technique represents the optimal integration of traditional craftsmanship with contemporary manufacturing technology. Let's examine the specific characteristics that make this fabric an exceptional choice for quality-focused garment production.

How does the jacquard loom mechanism function?

The jacquard loom's operational principle centers on its innovative control system. Prior to its development, complex pattern creation required manual manipulation of warp threads by skilled weavers—a labor-intensive and time-consuming process. The jacquard apparatus revolutionized this through its punched card system, automating thread selection with unprecedented precision and repeatability.

The jacquard loom operates through a programmed arrangement of punched cards or electronic signals that independently manipulate individual warp threads. This sophisticated control system enables the precise raising and lowering of thousands of threads in predetermined sequences, producing complex structural patterns directly within the fabric substrate rather than applying surface decorations.

What constitutes the fundamental operating principle?

The core mechanism employs a binary control system, conceptually preceding modern computational technology. Each warp thread connects to specific hooks controlled by punched card patterns. Where perforations exist in the programming cards, corresponding hooks engage, lifting designated threads to create the pattern structure. This systematic "activation/deactivation" sequence for each thread, repeated across numerous rows, progressively constructs the complete pattern from the foundation upward. This pioneering implementation of programmable patterning technology establishes the jacquard loom as a significant predecessor to contemporary computing systems.

How have technological advancements enhanced production?

While maintaining the fundamental operational principles, modern technological integration has substantially improved manufacturing efficiency. Contemporary jacquard looms predominantly utilize electronic controls and computer-directed operation rather than physical card systems. Design development now employs sophisticated CAD (Computer-Aided Design) applications that transmit pattern data directly to loom controllers. This technological evolution eliminates previous limitations associated with physical card production while enabling accelerated design modifications, enhanced pattern complexity, and improved manufacturing productivity, thereby increasing accessibility to premium jacquard textiles.

What varieties constitute the jacquard fabric category?

Jacquard classification refers not to a singular fabric type but rather to a comprehensive category defined by its distinctive weaving methodology. This technical classification permits production across diverse fiber types and finished characteristics while maintaining the essential attribute of structurally integrated patterning. The common denominator remains the sophisticated, woven-in design elements that distinguish these textiles across multiple applications.

Primary jacquard classifications encompass brocade, damask, matelassé, and jacquard knit constructions. Brocade exhibits raised patterning on characteristically lustrous ground fabrics, damask features reversible tone-on-tone designs, matelassé creates dimensional quilted effects, while jacquard knit specializes in patterned sweater and apparel applications—each offering distinct textural and aesthetic properties.

What distinguishes brocade from damask constructions?

Although both represent jacquard weaving techniques, brocade and damask frequently encounter classification confusion. The following analysis clarifies their distinctive characteristics:

| Characteristic | Brocade | Damask |

|---|---|---|

| Pattern Execution | Raised, embossed appearance | Reversible, flat patterning |

| Primary Fiber Content | Silk, synthetic compositions | Cotton, linen, silk variants |

| Ground Structure | Predominantly satin weave | Satin patterning on matte grounds |

| Visual & Textural Qualities | Ornate, dimensional, luxurious | Refined, subtle, sophisticated |

| Primary Applications | Formal attire, decorative upholstery | Table linens, drapery, apparel |

Brocade maintains recognition for its raised, frequently metallic-enhanced patterns delivering substantial, luxurious hand-feel. Damask conversely presents flatter, reversible construction prized for its understated elegance. Our manufacturing capabilities encompass both techniques, enabling client selection of optimal base fiber compositions for specific design objectives.

What advantages characterize jacquard knit applications?

Jacquard knitting implements comparable individual needle control principles to create integrated patterns within knitted constructions. This technology enables classic fair isle sweater patterns and contemporary graphic designs for modern athletic wear. The technical benefits include pattern integration within the fabric structure, eliminating print deterioration concerns while facilitating double-knit architectural elements that enhance thermal properties and durability. For brands developing distinctive knitwear collections, jacquard knitting presents extensive creative opportunities.

What factors determine jacquard fabric pricing?

The premium valuation of jacquard fabric directly reflects the substantial resources required throughout its manufacturing process. These textiles represent specialized products demanding significant craftsmanship, production time, and advanced technological infrastructure. From initial design development to final loom production, each manufacturing phase requires greater investment compared to standard weaving techniques, with resulting costs translating directly into enhanced product value.

Jacquard fabric commands premium pricing due to its complex, time-intensive manufacturing methodology, specialized loom capital requirements, extensive design programming necessities, and frequent utilization of superior quality yarns. The resulting product delivers exceptional durability, luxurious characteristics, and market-recognized value that justifies its price positioning.

Which production elements influence cost structure?

Multiple critical factors contribute to final cost determination:

- Design Development and Programming: Digital pattern creation for jacquard manufacturing resembles fabric engineering, with each design element corresponding to specific thread manipulation. This sophisticated research and development process represents significant initial investment.

- Loom Configuration and Production Rates: Jacquard looms operate at reduced speeds compared to standard weaving equipment. The intricate individual thread manipulation process extends production time, consequently reducing daily output capacity. Additionally, these specialized machines constitute major capital investment for manufacturing facilities.

- Technical Labor Requirements: Operation and maintenance of these advanced looms demand highly skilled technicians rather than conventional machine operators.

Does the premium investment yield satisfactory returns?

Undoubtedly. While initial cost per meter exceeds standard fabrics, jacquard materials enable premium pricing for finished products. Consumer perception recognizes these textiles as luxury commodities due to their distinctive texture, dimensional quality, and structural complexity. Enhanced durability further ensures extended product lifespan, strengthening brand reputation for quality. Selecting jacquard represents not merely fabric acquisition but strategic investment in premium product positioning that resonates with discerning market segments.

How to source premium jacquard fabric from Asian manufacturers?

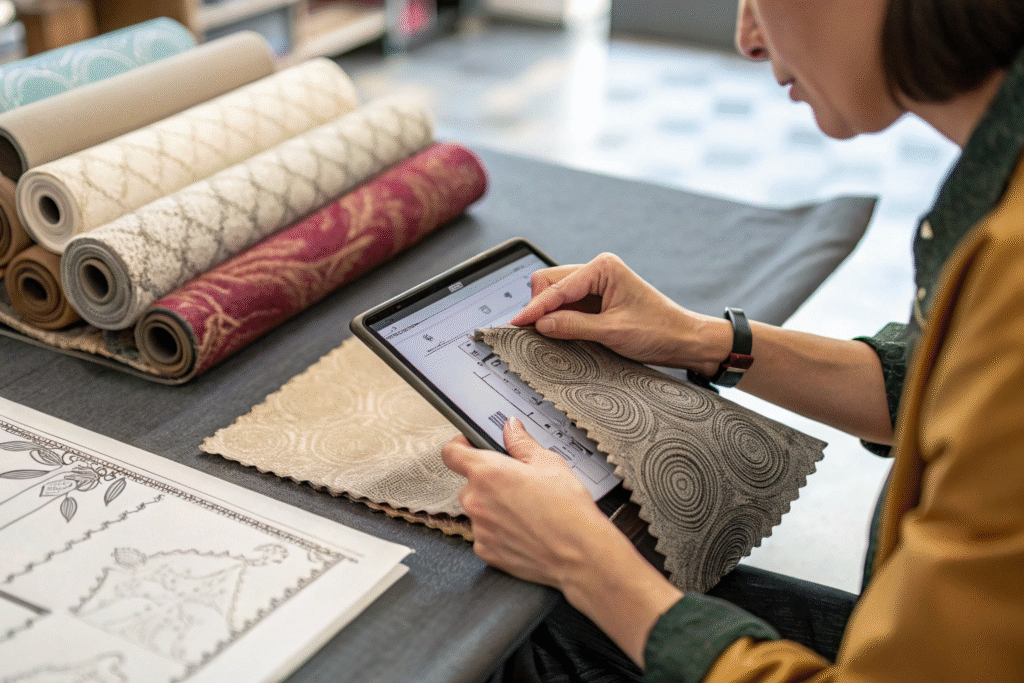

Sourcing high-caliber jacquard fabric necessitates partnerships with manufacturers possessing appropriate technical expertise and production infrastructure. As procurement specialists, businesses require suppliers maintaining comprehensive process control from raw material selection through final inspection. The critical success factor involves identifying manufacturers that successfully integrate traditional weaving expertise with contemporary efficient production methodologies and rigorous quality assurance protocols.

Successful jacquard fabric sourcing from Asia requires partnership with vertically integrated manufacturers specializing in jacquard production. Prioritize suppliers offering comprehensive design support, CNAS-certified laboratory facilities for quality verification, and documented experience supplying international markets, ensuring understanding of global composition, colorfastness, and safety standards.

What supplier qualifications ensure quality production?

Ideal manufacturing partners should demonstrate:

- Vertical Integration: Comprehensive control over weaving, dyeing, and finishing processes remains essential for quality consistency. Our manufacturing network includes proprietary weaving facilities and cooperative dyeing and finishing operations, ensuring uninterrupted quality management.

- Design and Prototyping Capabilities: Robust research and development resources are fundamental. We maintain 48-hour sample development cycles, facilitating rapid design iteration and accelerated market entry.

- Transparent Quality Verification: Detailed inquiry regarding testing protocols is essential. Our CNAS-accredited laboratory performs comprehensive testing including dimensional stability and color performance, with detailed reporting providing complete supply chain confidence.

How to manage international logistics and trade regulations?

This represents a frequent operational challenge, though experienced suppliers provide streamlined solutions. We maintain extensive expertise in global distribution, particularly to American markets. Our logistics management coordinates complete supply chain requirements from protective packaging to customs compliance. Furthermore, through utilization of our diversified supply chain networks and international trade initiatives, we consistently optimize shipping routes and associated costs. A significant advantage for our clients involves tariff-exempt status for our fabrics, delivering substantial cost efficiency and pricing predictability.

Conclusion

Jacquard loom weaving stands as enduring testament to textile manufacturing innovation, producing fabrics of exceptional beauty and structural integrity. The sophisticated manufacturing methodology, responsible for its distinctive textural patterning, fundamentally establishes its premium market position. From damask's timeless refinement to brocade's opulent dimensionality, jacquard fabric elevates any product incorporating its distinctive characteristics.

Jacquard fabric selection represents strategic investment in brand distinction and product longevity. This commitment to quality becomes immediately apparent to discerning consumers. For organizations prepared to explore jacquard fabric potential for upcoming fashion collections or interior textile applications, we invite consultation with our technical specialists. We provide comprehensive guidance through our extensive product portfolio and custom manufacturing capabilities. For detailed discussion regarding specific requirements, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. We look forward to transforming your design concepts into manufactured reality.