If you've ever been caught in heavy rain wearing a waterproof jacket that leaked, you might have experienced seam failure. The problem often isn't the fabric itself, but the tiny needle holes created during sewing. This is where bonding and seam taping become essential. For clothing brands and buyers sourcing weather-resistant apparel, understanding these processes is crucial for delivering products that perform as promised.

Bonding and seam taping are manufacturing methods used to seal the stitching holes in waterproof and windproof clothing seams. These techniques prevent water from seeping through the seams, ensuring the garment maintains its waterproof protection. Without proper seam sealing, even the best waterproof fabrics can leak. At Fumao Textiles, our twenty years of experience have shown us how proper seam sealing transforms adequate clothing into exceptional performance wear.

Let's examine these important processes and why they matter for your product sourcing decisions.

Why is seam sealing necessary for waterproof clothing?

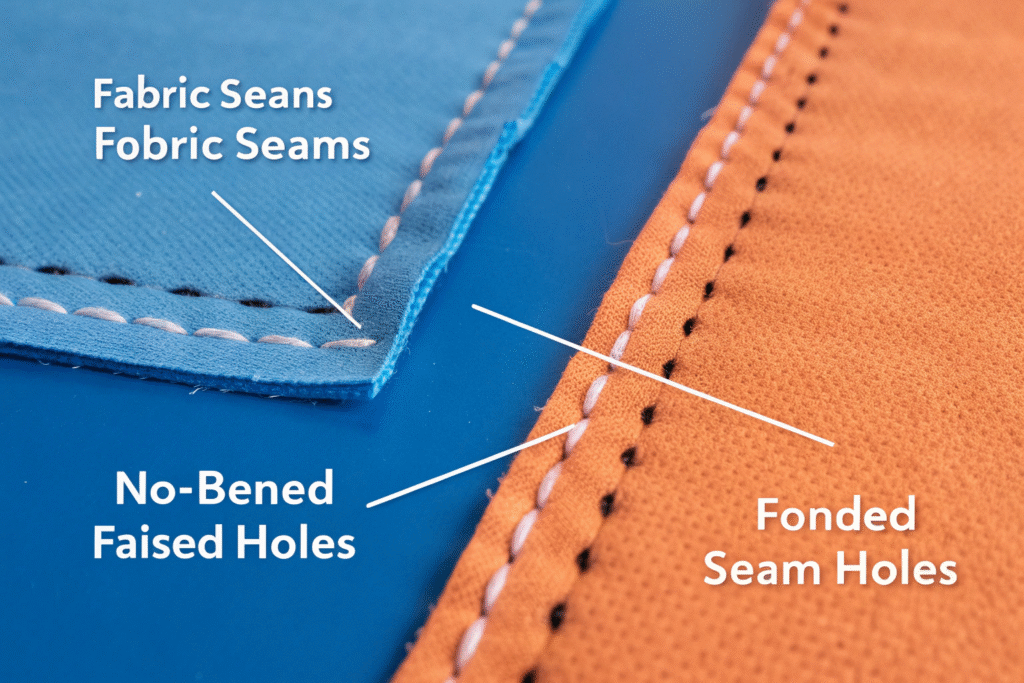

The main purpose of seam sealing is straightforward: to close the holes made by sewing needles. When fabric is stitched together, each needle puncture creates a potential entry point for water. Seam tape is a special adhesive material that is heat-applied over these stitched seams, forming a permanent waterproof barrier. This step is essential for achieving the waterproof rating claimed by the garment manufacturer.

Imagine your waterproof jacket as an umbrella. The main fabric repels water, but if the seams aren't sealed, water can drip through the stitching holes just like rain through an umbrella's stitches. This is particularly important in areas that receive the most weather exposure, such as shoulders and hoods. In our certified testing laboratory, we thoroughly examine taped seams to verify they can endure heavy rain and pressure, ensuring high quality standards for our clients.

How does seam tape stop water from leaking through stitches?

Seam tape prevents water leakage by forming a continuous waterproof layer over the sewing lines. The tape material is made from a plastic film that becomes sticky when heated. Using specialized heating equipment, we apply this tape with exact temperature and pressure control. The melted adhesive material flows into the needle holes, sealing them completely. The quality of application is vital; uneven application or wrinkles can create weak spots. We work with manufacturing partners who use advanced automated tape application equipment to achieve consistent, reliable results on every garment.

Which clothing items need sealed seams?

Not all clothing requires this type of seam treatment. Seam sealing is essential for garments where keeping out weather elements is a primary function. This includes rain jackets and pants for outdoor activities, ski and snowboarding clothing, sailing equipment, and protective work clothing for industries like construction and emergency services. Additionally, with today's active lifestyles, many wind-resistant running jackets and high-performance cycling clothes also use seam sealing to improve comfort and performance by blocking cold winds. It's an important feature that adds significant value to performance clothing.

How is fabric bonding different from regular sewing?

Fabric bonding, sometimes called welding or adhesive joining, represents an advanced alternative to traditional sewing. While sewing uses thread to join fabrics by interlocking loops, bonding uses heat, sound waves, or special glues to fuse fabric layers together. This approach eliminates needle holes entirely, creating seams that are naturally waterproof, stronger, and typically more comfortable since they lie flatter against the skin.

The benefits are significant. Bonded seams are lighter because they eliminate the weight of sewing thread. They're more durable since there's no thread to wear out and break over time. They also enable more innovative and streamlined designs. However, bonding isn't suitable for all situations. It works best with certain synthetic fabric types and requires sophisticated equipment. Our development team regularly collaborates with clients to create custom fabric combinations that work well with bonding techniques while maintaining the desired texture and feel.

What makes bonded seams better for some applications?

Bonded seams offer several advantages that benefit end-users:

- Better Weather Protection: By eliminating stitching holes, bonded seams provide superior waterproof performance.

- Increased Longevity: The bonded connection is often stronger than the fabric itself, reducing the likelihood of seam failure under stress.

- Lighter Weight: Without overlapping fabric edges and thread, garments weigh less and take up less space - important considerations for portable outdoor gear.

- Enhanced Comfort: Smooth, seamless construction reduces skin irritation and allows better movement freedom.

| Feature | Traditional Sewn Seam | Bonded Seam |

|---|---|---|

| Waterproofing | Requires taping for waterproofing | Naturally waterproof |

| Weight | Heavier due to thread and fabric overlaps | Lighter |

| Durability | Thread may wear and break over time | High seam strength |

| Flexibility | May restrict movement | Excellent flexibility |

| Production Cost | Lower | Higher |

When is conventional sewing preferable?

Despite the advantages of bonding, traditional sewing remains preferable in many situations. It's more adaptable, working with a broader variety of fabrics, including natural materials like cotton and linen that don't bond well. Sewing is also more economical for simpler garments or those not requiring complete waterproofing, such as fashion jeans or basic shirts. Additionally, for small production runs or complex designs where bonding equipment setup isn't practical, traditional sewing offers greater flexibility. The decision depends on selecting the right method for each product, and we assist our clients with this choice regularly.

What materials are used to seal seams against water?

The materials used for waterproof seams are as important as the application process. Incorrect tape or adhesive can separate, crack, or lose adhesion, making the entire waterproofing system ineffective. The main materials include seam tapes and specialized adhesives, each designed for specific fabric types and performance needs.

At Fumao, we recognize that different situations require different solutions. We provide and recommend suitable tape based on the base fabric characteristics. For example, a lightweight nylon shell for a running jacket needs different tape than a heavy-duty polyester fabric for ski wear. Our internal testing includes adhesion strength tests and low-temperature flexibility tests to ensure the tape remains securely attached and pliable even in extreme conditions, like those encountered by customers in cold climate regions.

What varieties of seam tape are available?

The most common seam tape types are categorized by their appearance and makeup:

- Standard Plastic Tape: This is the most widely used type. It comes in solid colors (usually matching the garment) and offers a good balance of durability, flexibility, and cost-effectiveness. It's appropriate for most waterproof and breathable fabrics.

- Clear Tape: Increasingly popular for visual reasons, clear tape creates almost invisible seam seals. It's ideal for dark or bright-colored fabrics where colored tape might look unattractive.

- Liquid Seam Sealant: This newer technology involves applying a liquid compound that hardens into a flexible waterproof seal. It's exceptionally lightweight and can be used on complex three-dimensional seams where conventional tape might not lay flat. This method is often employed by leading athletic wear brands pursuing advanced design and performance.

How is the right bonding adhesive selected?

Selecting the appropriate adhesive for fabric bonding depends on the fiber content of the materials being joined. The process typically uses thermoplastic polyurethane film as the bonding agent. When heated and pressed, this film melts and joins the two fabric layers together. The crucial factor is that the fabric's surface layer, usually made of polyester or nylon, must have melting characteristics compatible with the bonding film. Our technical specialists conduct detailed compatibility testing to determine the ideal temperature, pressure, and timing for each unique fabric combination, ensuring a lasting bond that survives the garment's lifetime.

How is quality maintained in seam sealing?

Maintaining quality in seam sealing requires a systematic approach combining technology, skilled workers, and thorough testing. It's not merely about operating tape application equipment; it's about establishing controlled conditions where every factor is managed to produce perfect, long-lasting seals. Quality control failures at this stage directly lead to product returns and damage to brand reputation.

Our comprehensive quality assurance system is why major purchasers rely on us. We don't just supply fabrics; we provide complete supply chain solutions, including guiding our manufacturing partners through correct seam sealing procedures. This includes everything from managing air moisture in production areas to inspecting taped seams under bright lights to identify any tiny gaps or air bubbles. Our quality inspection team performs random checks on finished garments, testing them with water pressure equipment to validate the seam seals.

What are typical seam taping problems?

Recognizing common defects is the first step toward prevention. The most frequent issues we identify and correct include:

- Wrinkles and Air Bubbles: When tape isn't applied smoothly, it creates passages for water entry and weak areas that may peel away.

- Surface Contamination: Dust or grease on the fabric surface before taping can stop the adhesive from forming a complete bond.

- Inadequate Heat or Pressure: This causes weak bonding where tape can be peeled off easily.

- Excessive Heat: This can burn the tape or underlying fabric, damaging the material's strength and making the adhesive brittle.

How is seam seal quality verified?

Quality verification is essential. We use several standard tests in our laboratory to ensure seam seals meet international quality standards:

- Water Pressure Test: This is the primary test. A sealed seam faces increasing water pressure, and we measure how much pressure it withstands before leaking. A quality garment will have seam performance matching its fabric rating.

- Adhesion Strength Test: This measures how much force is needed to peel the tape from the fabric. Strong adhesion indicates durable, long-lasting bonding.

- Low-Temperature Flexibility Test: The taped seam is repeatedly bent at below-freezing temperatures to ensure the adhesive doesn't become brittle and crack, which is essential for cold climate clothing.

Conclusion

Bonding and seam taping are much more than final manufacturing steps; they are critical processes that determine the true weather protection capability of waterproof and windproof garments. Understanding the purpose, materials, and quality standards behind these methods enables clothing brands and buyers to make informed sourcing choices and deliver products that genuinely meet performance expectations. This unseen technology builds visible customer confidence in your products.

If you're planning to develop high-performance, completely waterproof clothing with dependable, verified seam sealing, we should discuss your project. We possess the fabric knowledge, manufacturing network connections, and quality verification processes to ensure your next order meets the highest standards. For a direct conversation about your specific requirements, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. We're prepared to create value together with you.