For global sourcing professionals, understanding the practical applications of advanced materials is crucial. Aramid fabrics like Kevlar® and Nomex® represent a top-tier solution for protective gear, but what specific value do they offer for your next order?

Aramid fabric is a high-performance synthetic fiber prized for its exceptional strength, heat resistance, and durability. This makes it a primary choice for protective clothing, safeguarding personnel in high-risk sectors like firefighting, military, law enforcement, and industrial work against flames, ballistic impact, and cuts.

This guide will detail its specific uses, unique properties, and key sourcing considerations to inform your procurement strategy.

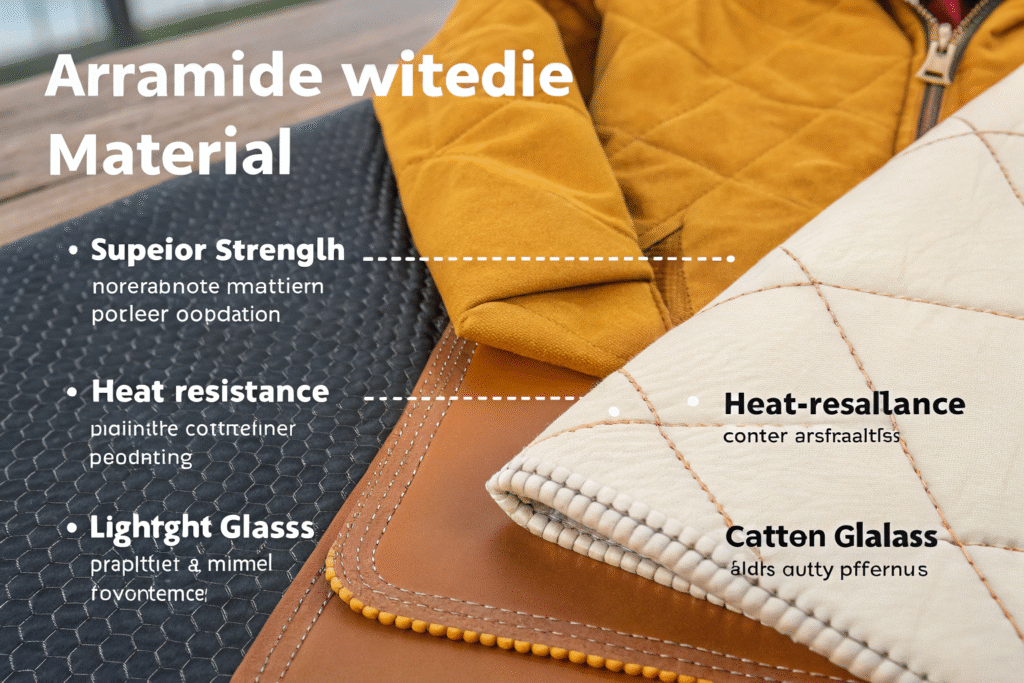

What are the key properties of aramid fabric?

Sourcing the right protective gear requires a deep understanding of the material. Aramid fibers deliver life-saving protection through a unique combination of inherent characteristics.

The core advantages of aramid fabric are its incredible strength-to-weight ratio, exceptional thermal resistance, and intrinsic flame retardancy. Unlike many synthetics, it won't melt or drip under high heat, creating a stable, protective barrier.

How does aramid fabric achieve its high strength?

The secret lies in its rigid, rod-like polymer structure. During production, these molecules become highly aligned, creating a strong crystalline formation that delivers immense tensile strength. This makes the fibers extremely difficult to pull apart, which is why it's ideal for ballistic protection and cut-resistant gear. Remarkably, it can absorb and disperse more energy than steel on an equal weight basis.

Why is it so resistant to heat and flame?

The same robust molecular structure provides outstanding thermal stability. The aromatic polymer chains require immense energy to break. When exposed to flame, aramids like Nomex® carbonize and thicken, forming a protective, insulating char that shields the wearer's skin. This intrinsic reaction provides critical escape time in flash fires.

What types of protective clothing use aramid fabric?

Aramid fabrics are engineered for specific threats. Matching the right material to the hazard ensures both safety and cost-efficiency.

Its primary applications fall into three categories: thermal and flame-resistant gear, ballistic and stab-resistant body armor, and cut-resistant industrial apparel.

Which gear is made for thermal and flame protection?

This is the classic use for fibers like Nomex®. Aramid is essential for environments with flash fires, arc flashes, or molten metal splash. It's used in complete firefighter turnout gear (outer shell, moisture barrier, and thermal liner) and industrial FR clothing for oil and gas, electrical, and motorsports professionals.

How is it used in ballistic and stab protection?

For ballistic threats, Kevlar®'s high tensile strength is key. Multiple woven layers in soft body armor absorb and stop a bullet's energy. For stab resistance, specialized constructions like chain mail laminates or dense felts resist punctures from blades and spikes, making it vital for law enforcement and corrections.

How does aramid compare to other protective fabrics?

Sourcing involves trade-offs. Aramid's balanced performance often makes it the superior choice, but understanding the alternatives is key.

Aramid offers a better balance of strength, heat resistance, and light weight than many alternatives, though at a higher initial cost. It outperforms FR cotton in durability and protection and is more flexible and comfortable than fiberglass or leather.

Is aramid better than FR cotton for long-term use?

While FR cotton is cost-effective for low-risk scenarios, its chemical treatment can degrade over time. Aramid's protection is built into the fiber, lasting the garment's lifetime. This makes it more reliable and cost-effective long-term for demanding applications.

What are its advantages over fiberglass and leather?

Fiberglass is heat-resistant but brittle and inflexible. Leather offers abrasion resistance but is heavy and not inherently flame-resistant. Aramid's critical advantage is combining lightweight flexibility with high tensile and thermal protection, enhancing mobility and wearer compliance.

What should you consider when sourcing aramid clothing?

Beyond technical specs, a smart sourcing decision hinges on compliance, total cost, and supply chain reliability.

Focus on three areas: verifying industry certifications, evaluating the total cost of ownership, and ensuring your supplier has robust quality control and a tariff-resilient supply chain.

Why are certifications non-negotiable?

Certifications (NFPA, ISO, CE) provide objective proof of safety standards. Always request test reports from an accredited laboratory. Our in-house CNAS-accredited lab, for instance, ensures every batch meets international standards, providing verifiable confidence.

How to evaluate true cost and the supply chain?

Look beyond the unit price. Aramid's durability reduces replacement frequency, and its comfort improves worker productivity. Geopolitical factors like tariffs are a real concern. A supplier with a diversified network, including overseas warehousing, mitigates these risks, ensuring stable pricing and reliable delivery.

Conclusion

Aramid fabrics are engineering essentials for critical protection. Their unique combination of properties makes them indispensable for safeguarding lives. Understanding these factors empowers you to make informed decisions that balance safety and performance.

Ready to source high-quality aramid fabric? With over 20 years of experience, we provide end-to-end solutions from development to tariff-optimized shipping. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your specific needs and build a safer product line.