In the realm of smart textiles and advanced performance wear, PCM (Phase Change Material) fabrics are rapidly gaining popularity for their ability to regulate temperature in real time. By absorbing, storing, and releasing heat, these fabrics offer comfort in fluctuating environments—making them ideal for sportswear, outdoor gear, bedding, and even medical garments.

But while demand for PCM textiles is rising, many apparel brands and startups hesitate due to uncertainty around production minimums. These smart fabrics often involve high material cost, functional coating technology, and complex lamination processes that impact MOQ (Minimum Order Quantity).

At Fumao Fabric, we work with both high-volume and experimental clients, offering flexible PCM integration options—coated, encapsulated, or blended—at scalable minimums for sampling, pilot, and full production.

What Is PCM Fabric and How Does It Regulate Temperature?

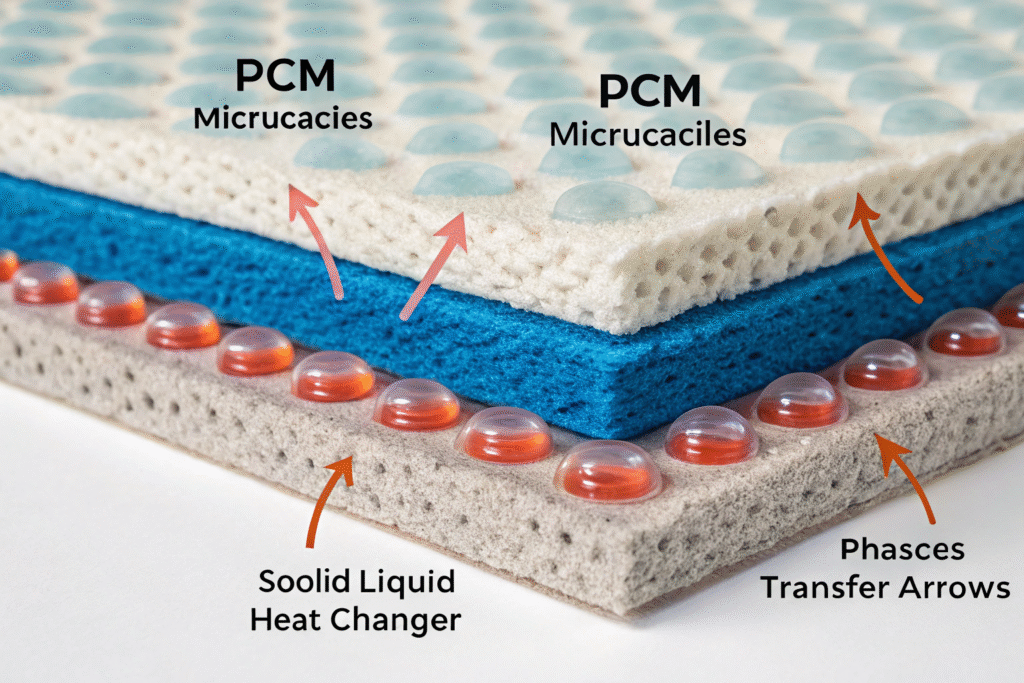

PCM (Phase Change Material) technology is based on microencapsulated waxes or polymers that change phase (solid ↔ liquid) at a specific temperature threshold—usually between 28°C–32°C for apparel.

These PCMs are embedded in fabric coatings, fibers, or laminates. When the body heats up, the PCM absorbs heat by melting; when the temperature drops, it solidifies and releases stored heat—creating a buffering effect.

How Is PCM Technology Applied to Textiles?

PCM can be applied via:

- Microcapsule Coating: Bonded to surface or laminated layer

- Fiber Extrusion: Incorporated during spinning

- Print Application: Printed using binders onto finished fabric

We work with materials such as Outlast® and Thermore® Ecodown PCM lines, both of which meet OEKO-TEX and REACH standards.

What Are the Benefits of PCM-Enhanced Fabrics?

- Thermal regulation ±2–3°C

- Reduces overheating and chills

- Improves microclimate comfort for skin

- Reduces energy use in bedding and apparel

- Ideal for athleisure, workwear, bedding, and technical underlayers

What Are the Typical MOQs for PCM Fabrics?

The minimums for temperature-adaptive PCM fabrics depend on the application method, coating chemistry, and fabric base. Unlike standard knits or woven yardage, PCM fabrics involve additional R&D, licensing, and setup costs that influence MOQs.

For coated or laminated PCM textiles, MOQs usually range from 300 to 1000 meters per color or formulation. For fiber-integrated PCM, the minimums are significantly higher due to extrusion batch limits.

What Are MOQ Ranges by PCM Type?

| PCM Format | MOQ (per color) | Notes |

|---|---|---|

| Microcapsule Coating | 300–500 meters | Suitable for base layers and bedding |

| PCM Film Lamination | 500–800 meters | For jackets, gloves, structured items |

| PCM Fiber Integration | 3000–5000 meters | High-capex melt extrusion |

| PCM Print Paste | 200–300 meters | Flexible but lower performance |

For specialty clients, we offer PCM-backed swatchbooks and lab dip MOQ at 50m for R&D trials.

Can Startups or Small Brands Access PCM Fabrics?

Yes—with proper supplier negotiation or through intermediaries like Fumao. We offer:

- Shared batch production

- Stock-supported popular formulations (30°C PCM)

- MOQ reduction through base fabric substitution

- Custom MOQ calculator based on coating + fabric + performance target

Explore small-lot sourcing support from FabricLink and SmartexLab.

What Should Buyers Consider Before Sourcing PCM Fabrics?

Before sourcing PCM fabrics, buyers must clearly define their use-case, target performance temperature, durability expectations, and end-customer environment. PCM fabrics are highly technical and their success depends on good calibration between fiber, function, and fashion.

It’s also critical to request performance testing data and batch traceability, especially if the product is designed for regulated markets or claims heat regulation.

What Tests Should Be Done on PCM Fabrics?

- Differential Scanning Calorimetry (DSC): Confirms heat absorption/release curve

- Thermal Conductivity (ISO 8301)

- Cycle Stability: 30–50 wash cycles (for durability)

- Handfeel & Flexibility Test (especially with coatings or films)

For apparel, AATCC wash stability and pilling tests also apply.

What Key Questions Should Be Asked Before Ordering?

- What is the exact PCM content (g/m²) and trigger temperature?

- Is the PCM microencapsulated or bonded?

- What are the MOQ, lead time, and swatch cost?

- What’s the maximum number of wash/dry cycles it can endure?

- Can I receive DSC test results and tech data sheets?

At Fumao, we provide these reports alongside export documentation and thermal test visuals.

How Can Fumao Help Brands Source Low-MOQ PCM Fabrics?

At Fumao Fabric, we specialize in bridging the gap between innovation and scalability. We provide PCM coating and lamination on both synthetic and blended bases, tailored for outerwear, bedding, accessories, and workwear.

For brands seeking to prototype, scale, or diversify thermal-regulating products, we offer a hybrid sourcing model that includes lab sampling, small-batch coating, and full MOQ production.

What PCM Options Do We Offer?

- 30°C phase change coating on polyester microfiber

- PCM lamination on nylon stretch for gloves or jackets

- PCM knit blends (poly-viscose-spandex) for base layers

- Biobased PCM coating with GRS-compatible substrates

Our test lab uses DSC and IR scanning to confirm performance curves and stability across temperature ranges.

What Is Our MOQ Support Policy?

- Swatch sample kit: Available with 5 PCM-treated fabrics

- Lab dip trial: MOQ 50–100m

- Pilot run: Starts at 300m/color

- Full production: 800–1000m/color (custom coatings)

We also help clients label fabrics as "Thermal Adaptive" or "Smart Cooling Fabric" with SGS/OEKO-TEX compatibility.

Conclusion

PCM fabrics are no longer niche—they're becoming essential for brands that serve performance, athleisure, bedding, and medical segments. However, sourcing these high-function textiles requires careful planning, supplier vetting, and understanding of MOQ structures tied to coating and formulation complexity.

At Fumao Fabric, we simplify the process by offering flexible MOQs, sample-ready formulations, and expert guidance. Whether you're prototyping a smart sleep blanket or launching a thermo-active hoodie, we help you integrate PCM tech without overshooting your volume needs.

To begin sourcing temperature-adaptive PCM fabrics with flexible minimums, contact our Business Director Elaine at elaine@fumaoclothing.com for fabric swatches and test-backed specs.