The demand for antimicrobial and self-cleaning fabrics has surged in recent years, driven by heightened awareness of hygiene and health safety in both fashion and industrial applications. As a manufacturer deeply rooted in the textile hub of Keqiao, I have watched this trend grow from niche healthcare fabrics to a mainstream demand in activewear, upholstery, and even baby products.

Copper alloy fabrics have emerged as a star player in this revolution. Their natural antimicrobial properties are being enhanced through advanced nanotechnology, innovative coating processes, and creative fabric structures. Today, these materials are more than just functional—they’re also stylish, sustainable, and scalable for mass production.

In this article, I will walk you through the latest developments in self-sterilizing copper alloy fabrics, from their material science to their applications, so you can understand why they’re becoming essential for modern textile buyers and designers.

Copper-Impregnated Textiles for Everyday Protection

Copper-impregnated textiles are among the oldest yet most reliable methods for creating antimicrobial fabrics. In this process, copper ions are embedded directly into the fibers during spinning or extrusion, ensuring the antimicrobial effect remains throughout the fabric’s life cycle.

These fabrics are widely used in hospital bedding, athletic socks, and even casual wear where long-term antibacterial protection is essential. The copper ions disrupt bacterial cell walls and neutralize pathogens on contact, offering a passive yet effective method of hygiene.

How Do Copper-Ion Embedded Fabrics Maintain Performance Over Time?

Copper ions are bound within the fiber matrix, which means their antimicrobial activity is not simply a coating that can wash away. According to Fibre2Fashion, even after 50+ wash cycles, many copper-embedded fabrics retain over 90% of their antimicrobial properties. The challenge lies in balancing copper content with softness and breathability—too much copper can affect hand feel, while too little reduces efficacy.

Another advancement is blending copper yarns with organic cotton or bamboo fibers, which makes the fabric more sustainable and suitable for sensitive skin applications like baby blankets.

What Are the Commercial Applications of These Fabrics?

From medical linens to travel gear and high-performance sportswear, copper-impregnated fabrics are versatile. They offer not only hygiene benefits but also odor control, making them ideal for markets where freshness is a selling point. Hotels, gyms, and airlines are starting to adopt these fabrics for added customer safety.

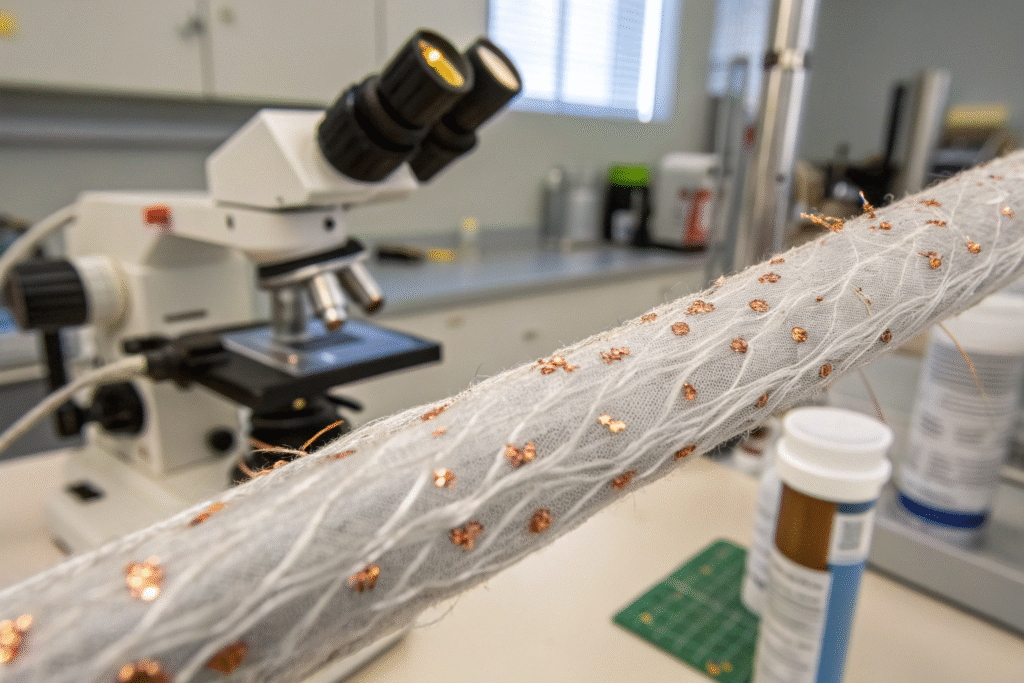

Durable Copper-Nanoparticle Coated Cotton

Recent breakthroughs in nanotechnology have allowed manufacturers to attach copper nanoparticles (CuNPs) to cotton fibers with strong chemical bonds, ensuring long-lasting antimicrobial performance without compromising fabric softness.

The process typically involves a binder, such as thioglycolic acid, which secures the nanoparticles to the cotton’s surface. Tests published in SpringerLink show fabrics maintaining over 96% antibacterial efficiency against S. aureus and E. coli after 50 laundering cycles.

Why Are Copper-Nanoparticle Coatings More Effective Than Traditional Finishes?

Traditional antimicrobial finishes can fade after repeated washes. In contrast, nanoparticle coatings integrate at the molecular level, resisting wear and maintaining performance over time. This makes them especially valuable for uniforms, reusable medical gowns, and sports apparel where frequent laundering is unavoidable.

Beyond bacterial protection, copper nanoparticles can also neutralize certain viruses and fungi, providing a broader spectrum of defense—critical in high-contact environments like hospitals and public transport seating.

Can These Fabrics Be Produced at Scale for Commercial Buyers?

Yes. While nanoparticle technology used to be expensive, advancements in chemical vapor deposition and plasma treatment have made it more accessible for mass production. Our own partner facilities in Zhejiang now produce copper-nano cotton at competitive prices for export to the US and EU, meeting stringent testing standards like SGS and ITS.

Copper-Based Superhydrophobic Self-Cleaning Fabrics

Superhydrophobic fabrics repel liquids, making them resistant to stains and microbial growth. When combined with copper treatments, they offer a powerful dual function—self-cleaning and self-sterilizing.

This is achieved by applying a copper-stearic acid coating, which creates a nanoscale roughness that repels water. According to Cellulose Journal, these fabrics can maintain their water-repelling ability after multiple washes while still killing up to 99% of bacteria.

What Makes Copper Superhydrophobic Fabrics Stand Out?

Unlike traditional water-repellent fabrics that rely solely on fluoropolymers (which can be environmentally harmful), copper-based coatings are both functional and eco-friendlier. They resist not just water but also oils and dirt, meaning garments require less frequent washing—saving water and energy.

They are ideal for outdoor gear, military uniforms, and public seating covers, where exposure to liquids and dirt is common. Combined with copper’s antimicrobial action, they offer all-in-one protection.

Are These Fabrics Suitable for Fashion as Well as Industry?

Absolutely. Designers are beginning to incorporate these fabrics into raincoats, handbags, and even footwear. The copper sheen can be subtle or highlighted depending on design intent. Brands aiming for a tech-fashion appeal can market these as premium, performance-oriented products with long-term durability and hygiene benefits.

Active Copper Coatings for Instant Pathogen Neutralization

One of the most exciting recent developments is “Active Copper” (aCu), a mesostructured copper material with extremely high surface area. This structure enables it to inactivate viruses, including SARS-CoV-2, in under 60 seconds.

The coating can be applied as a thin gel or paste to a variety of textiles without significantly altering their flexibility. Research from News-Medical shows that aCu-coated fabrics achieve complete viral inactivation in laboratory settings.

How Does Active Copper Achieve Such Fast Results?

The mesostructured copper particles have a vast surface area, allowing more contact points with pathogens. This accelerates the ion release and oxidative stress mechanisms that destroy viral and bacterial cells. Unlike silver-based coatings, copper works even in dry environments, which is crucial for fabrics used in masks and HVAC filters.

Could This Technology Transform PPE and Everyday Clothing?

Yes. PPE manufacturers are already testing aCu for face masks, gowns, and gloves. Everyday clothing brands could integrate this coating into commuter wear, scarves, or gloves for added protection. The potential also extends to air filtration systems in public buildings, where copper-coated filters can reduce airborne pathogen transmission.

Conclusion

Self-sterilizing copper alloy fabrics have evolved from niche hospital products to mainstream textile innovations. With advances in nanotechnology, coating chemistry, and sustainable manufacturing, these fabrics now serve industries ranging from healthcare and sports to fashion and hospitality.

By combining copper’s natural antimicrobial power with design flexibility, we can create fabrics that not only protect but also inspire. The global shift toward hygiene-conscious living ensures these materials will continue to grow in demand.

If you’re interested in developing your own custom copper-infused fabric line, we at Shanghai Fumao have the expertise, production capacity, and global logistics network to deliver. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your project and bring your concept to life.