I talk to buyers every week who ask the same question: when will spider-silk-like textiles move from lab demos to dependable mill-ready yarns? The promise sounds irresistible—light, tough, silky, and bio-based—but my customers care about repeatability, MOQ, dye fastness, and lead time. I will break down what is real today and what is almost there, so you can plan your next-season line with fewer unknowns.

In short, lab-grown “spider silk” is exiting the hype cycle and entering selective commercialization. Fermentation-based proteins are scaling with help from food-grade bioprocessors, new solvent-free spinning routes are emerging, and transgenic silkworms are producing stronger filaments. Still, there are constraints: pricing, yarn uniformity, finish compatibility, and color matching at bulk speeds. I will explain what you can reliably buy or co-develop now, what needs pilot trials, and how we at Fumao Fabric can integrate these fibers into real apparel programs.

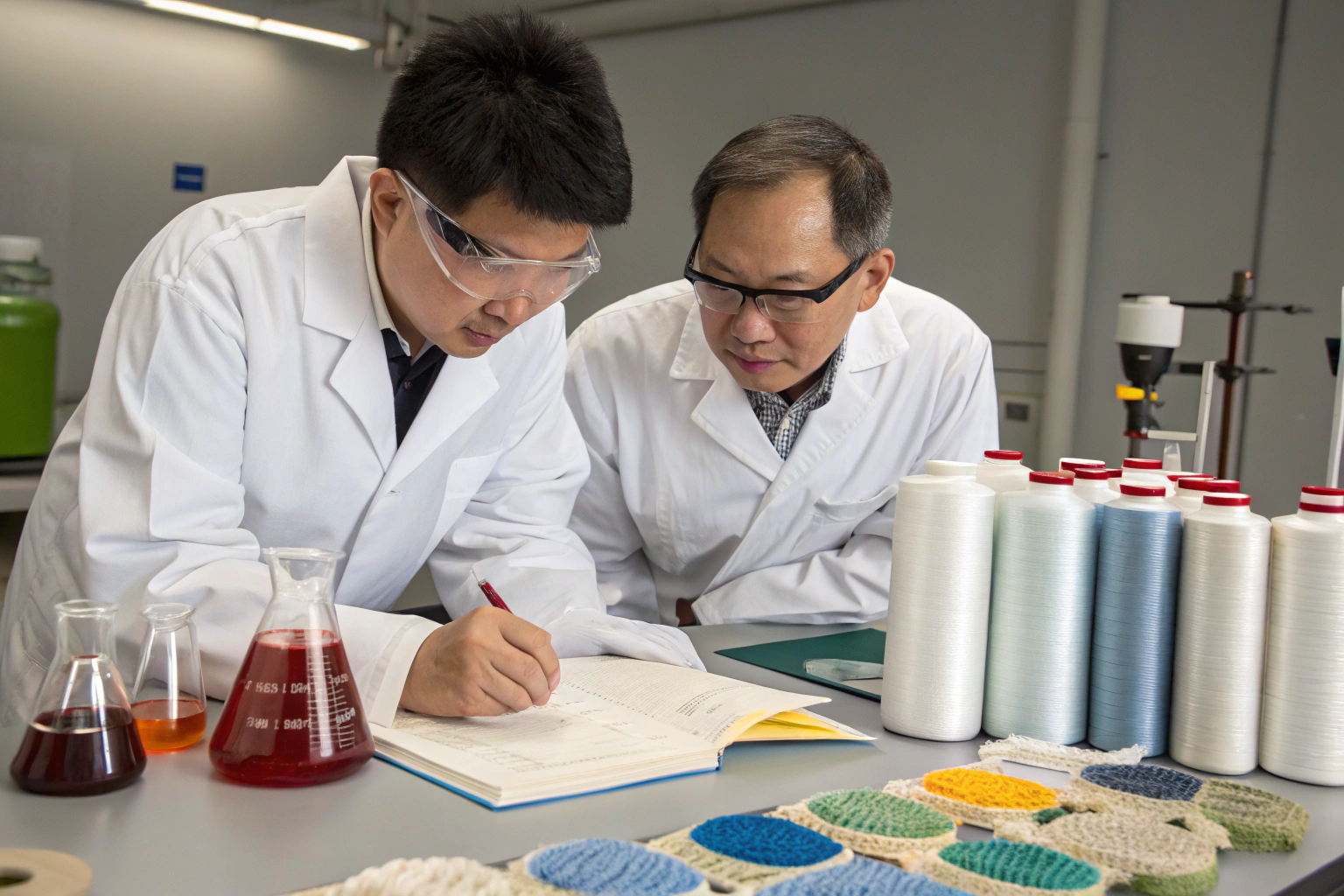

I have run proofs with mills in Keqiao and sat in biopolymer rooms that smell like soy mash. I have seen both failed bobbins and beautiful cones. If you are a U.S. buyer like Ron, your priorities are quality assurance, sampling speed, and an honest TCO including logistics and duties. Keep reading, and treat this as your field guide.

Is Lab-Grown Spider Silk Ready for Scale?

Buyers feel pressure from sustainability KPIs and new materials briefs. The pain is real: you need MOQ-friendly, color-consistent yarns and dependable delivery windows. You may have tested “vegan silk” samples before, only to hit dead ends. I understand the frustration. That is why I track each supplier’s actual plant status, not just press releases.

Yes—partly. Fermentation players expanded capacity through partnerships with established bioprocessors, and couture capsules are proving hand-feel and drape. However, full mass-market basics still face price and yardage constraints. Expect premium placements first (outerwear panels, trims, limited jerseys), then broader rollouts as reactors, dope prep, and draw ratios stabilize.

To go deeper, separate brand storytelling from run-rate math. Ask about reactor throughput (kg/day), dope concentration, spinneret L/D, draw-down ratios, and winding speeds. Check if their protein is a direct spidroin analog or a proprietary “inspired” sequence. Confirm dye class compatibility and post-finish windows (enzyme, C6-free DWR, PU-coat). Request third-party data from CNAS/SGS/ITS for tensile, tear, abrasion, and pilling. Then run your own lab dips and pilot yardage in our Keqiao network to validate colorfastness and shrinkage before committing.

Are fermentation players truly shipping product now?

Couture and collab capsules show real fabric on the runway and in limited drops. One high-profile example used Brewed Protein™ in couture this summer, signaling readiness beyond lab cloth. Many mills, including us, can knit trial lots when protein dope or staple is supplied. Cross-check whether the supplier runs in Thailand, Japan, or the U.S. and if corn dextrose feedstock ties into regenerative programs. See the material overview at Spiber and fashion applications via Vogue Business.

What about scale via bioprocess partners?

Scale hinges on partners with fermentation know-how, utilities, and QA culture. Some players co-locate with grain processors to secure sugar streams and wastewater handling; others partner with European amino-acid experts. Read partner announcements at ADM and fermentation updates from AMSilk. These relationships matter to your lead times, because they determine output regularity and price curves.

Microbial vs. Silkworm: Which Route Wins?

Product managers ask me to compare two routes: microbial fermentation (then solution spinning) versus transgenic silkworms producing enhanced filaments. Your risk profile changes with each option. Microbial lines look like food tanks; silkworm lines look like classic sericulture with smarter genetics.

Both routes are viable, but the product profiles differ. Fermentation offers tunable proteins and diverse formats (filament, staple, film, foam). Transgenic silkworms promise cost-efficient reeled filaments at silkworm-like scales, leveraging existing cocoon infrastructure. If you need knit-friendly multifilaments and brand-new hand-feels, fermentation leads. If you value filament reeled continuity and potential cost-down with scale, keep watching the silkworm route.

I advise buyers to pilot both routes. Use fermentation yarns for trims, logos, yokes, and small-lot capsules. Use transgenic silk when reeled meters align with weaving plans. In our lab, we compare warp breakage, weft insertion rate, needle heat tolerance, and cover factor under real finishing lines. That is how we avoid expensive surprises.

Do transgenic silkworms finally deliver stronger filaments?

Recent announcements show progress using Darwin’s bark spider genes to boost strength and elasticity in silkworm silk. A new production center in Vietnam indicates a path toward larger supply. You should still audit cocoon uniformity, reelability, and degumming behavior. Read more from Kraig Labs and facility news via Specialty Fabrics Review. These updates suggest better yarn strength without fully abandoning sericulture economics.

How does microbial protein become yarn we can actually knit?

Suppliers express engineered proteins in microbes, purify them, then prepare a spinning dope and extrude through a spinneret. They draw and anneal filaments to set beta-sheet domains for strength. See an accessible tech explainer at Bolt Threads Microsilk and a biotechnology perspective from 21st.BIO. In our practice, the devil is in rheology and draw ratios. Small shifts in solids or coagulant can change hand-feel and pilling by a lot.

Spider Silk Blends for Performance Apparel

Sportswear managers want moisture management, stretch recovery, and soft drape without microplastic shedding. They ask me if “spider silk” can replace nylon or polyester in key SKUs. The answer depends on blend design, yarn count, and finishing.

Blends are the near-term win. Spider-silk-inspired fibers blended with recycled polyester, nylon 6, or cellulose improve hand-feel, reduce odor retention, and may enable lower-temperature dyeing. For athleisure, use them in face yarns or zoned panels where touch and drape matter most. Keep the back yarn conventional for abrasion and price control. For trims, pure bio-protein filaments can shine.

We have knitted 28–36 gg jerseys that pass snag, pilling, and stretch recovery targets when we tune stitch density and finish chemistry. We also coated woven shells where spider-inspired yarns add quietness and a premium hand. Below, I share the questions I ask in every blend trial.

Can we meet real sports specs without harsh solvents?

A key innovation comes from solvent-free spinning that mimics spider spinnerets. One UK player claims ~1000× energy efficiency vs. petroleum fibers and uses water as the only byproduct. This matters for ZDHC and for your Higg data. Read about the approach at Spintex and a summary on AskNature. When we specify finishes, we choose bluesign-approved chemistries from bluesign and align with ZDHC MRSL. These choices protect hand-feel and certification pathways.

What finishing and testing plan should we budget?

Plan a finish matrix: enzyme wash vs. softener, C0 DWR vs. none, and heat-set windows. Book third-party tests for tear (ASTM D1424), abrasion (Martindale ISO 12947), and colorfastness (AATCC 61). For biodegradation or compostability claims in packaging or trims, reference ASTM D6400 and broader guidance from AATCC and ISO. We also log results in QR-linked lab sheets so your sourcing team can audit every meter.

Sustainability, Standards & Real Costs

U.S. buyers want truth over hype. They ask me what spider-silk-inspired textiles do for climate and what the landed cost looks like. I give them the same answer I give my own team: measure everything, and model the full cost—from sugar feedstock to final garment logistics.

Sustainability depends on process, not slogans. Look for suppliers tied to regenerative feedstocks and energy-efficient spinning. Request LCA summaries and align labelling with standards you can defend. For cost, assume pilot premiums this year, with blended SKUs as the practical path. Negotiate supply security clauses and transparent surcharge formulas tied to feedstock prices and shipping indices.

At Fumao Fabric, I control variables by co-locating weaving, dyeing, printing, coating, and packaging partners around Keqiao. Our CNAS-accredited testing, QR traceability, and 48-hour sample development help you make decisions fast. For U.S. lanes, we plan booking windows and tariff classifications early so there are no surprises.

Which labels and claims can we safely make on hangtags?

Use recognized standards and avoid overclaims. For chemical management and mills, look to OEKO-TEX and bluesign. For recycled components in blends, rely on GRS. If your supplier cites regenerative agriculture for feedstock, ask for program documentation—see examples tied to Brewed Protein feedstocks via ADM. Keep your marketing team aligned with FTC Green Guides.

How do we model landed cost and tariff exposure?

Map your HS codes early. Traditional silk uses Chapter 50; bio-based, non-animal protein yarns or blends may fall under man-made categories in Chapter 54 or 55 depending on composition. Confirm with your customs broker and the U.S. ITC HTS Search. Then add ocean freight and drayage. For material risk, track supplier financials; some venture-backed innovators pivot between products—read historical context at Bolt Threads and industry reporting from Vogue Business to calibrate your scenario planning.

Conclusion

Spider-silk-inspired fabrics are moving from promise to practice. Fermentation lines, solvent-free spinning, and transgenic silkworms each add a piece to the puzzle. The near-term sweet spot is in blends and premium placements where hand-feel and story justify cost. The way to win is not by waiting for perfection but by running structured pilots now: confirm properties with third-party tests, lock finishing recipes, and model real logistics.

If you want to turn this into an actual line, my team at Shanghai Fumao will build a program around your goals. We will develop samples within 48 hours, run controlled knitting or weaving trials, and deliver export-ready yardage with CNAS documentation and QR traceability. To start a spider-inspired fabric capsule or trims program, contact our Business Director Elaine at elaine@fumaoclothing.com. We will co-create value from the first lab dip.