When it comes to shapewear, fabric choice is everything. The wrong material can lead to rolling edges, excessive heat retention, or garments that simply don’t sculpt or support. But the right stretch satin? It’s transformative—offering sleek compression, silky aesthetics, and adaptive comfort. So, what exactly makes some stretch satin fabrics perfect for shapewear, and where should you look for the best options?

The best stretch satin fabrics for shapewear combine high spandex content, tight weave structure, low-gloss finish, and four-way stretch recovery. These materials offer both control and luxury, and are commonly produced using nylon/spandex or polyester/spandex blends.

In this guide, I’ll explain the technical, tactile, and sourcing aspects of choosing premium stretch satin for shaping garments that hug, hold, and flatter.

What Defines High-Performance Stretch Satin for Shapewear?

Not all stretch satin fabrics are created equal. While many look smooth and shiny on the surface, shapewear demands more than just a pretty finish. It needs strength, retention, and confidence-building coverage.

High-performance stretch satin for shapewear typically consists of 15–25% spandex blended with nylon or polyester, achieving four-way stretch and strong recovery. GSM usually ranges from 180–280 to ensure compression and opacity.

What Fiber Combinations Work Best?

| Fiber Blend | Key Benefits | Use Case |

|---|---|---|

| Nylon/Spandex | Superior recovery, soft handfeel | Mid- to high-compression bodysuits |

| Polyester/Spandex | Cost-effective, moisture-wicking | Light control briefs or panels |

| Microfiber Blends | Smooth, matte finish | Seamless shapewear or base layers |

For deeper fiber insights, check Textile Exchange’s material directory or Spoonflower’s guide on satin types.

What Is the Ideal Satin Structure for Shapewear?

Shapewear-specific satins should have:

- Dense weave to prevent sheerness

- Moderate sheen (not high-gloss)

- Four-way stretch for flexibility in motion

- Matte-back or brushed inside for skin comfort

We supply these in warp-knitted double-faced satin and anti-curl tricot-based satin with stretch levels of 140–160%. For detailed testing methods, visit ASTM D3770 stretch recovery standards.

Which Shapewear Garments Use Stretch Satin Most Effectively?

The applications of stretch satin in shapewear go beyond corsets. Modern silhouettes use these fabrics in subtle yet supportive ways—offering structure and comfort with sleek elegance.

Stretch satin is used in bodysuits, bust shapers, smoothing shorts, and control slips where the fabric needs to contour, support, and glide smoothly under clothing.

Why Is It Ideal for Bodysuits and Slips?

Stretch satin holds its shape and resists sagging, making it perfect for:

- Full-body control suits

- Bust-lifting cami bodysuits

- Mid-thigh slips for under dresses

Brands like SPANX and SKIMS utilize satin blends with high spandex content for mid-to-high compression shapewear, emphasizing seamless control with a luxurious feel.

Can It Be Used in Lightweight Shaping Pieces?

Yes. For less compression and more layering comfort, satin can be used in:

- Tummy control panties

- Shaping bras or bandeaux

- Waist cinchers with lace overlay

For intimate category innovation, visit WGSN’s lingerie material reports and explore trending silhouette-to-fabric pairings.

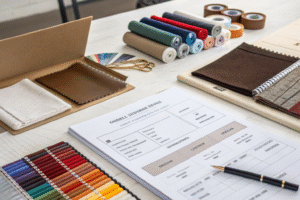

What Are the Top Specs to Request from Suppliers?

Knowing what to ask from your supplier is key to consistency. Whether developing for mass-market or boutique shapewear brands, you need clear data—not just a shiny sample.

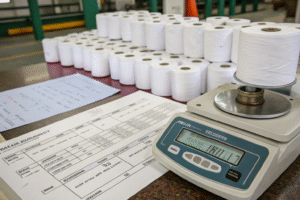

Key specs include GSM, fiber content, elongation and recovery %, shrinkage %, colorfastness, and heat resistance. Always request batch testing reports from third-party labs like SGS or Intertek.

What Are Standard Technical Benchmarks?

| Parameter | Recommended Value |

|---|---|

| GSM | 180–280 |

| Stretch (weft) | 130–160% |

| Recovery | ≥95% |

| Shrinkage | <3% |

| Pilling Resistance | Grade 4+ |

| Washfastness | Grade 4–5 (AATCC 61) |

We at Fumao Fabric ensure these properties through our CNAS-certified lab, issuing QR-coded test reports with every satin batch. You can reference fabric specs from OEKO-TEX Standard 100 certified mills.

How Can You Ensure Color Consistency?

For shapewear basics (black, nude, mocha, rose beige), color continuity is crucial across repeat orders. Ask for:

- Lab dips on original base fabric

- Spectrophotometer readings

- Lightbox visual review

Color tolerance (ΔE) should remain within ±1.0 for true consistency. See Datacolor’s resources on color management in stretch textiles.

Where to Source Quality Stretch Satin for Shapewear?

Finding the right fabric partner can make or break your shapewear line. The best sources offer testing data, consistent QC, low-MOQ development options, and fast lead times for sampling and bulk.

Top suppliers of shapewear-grade stretch satin are located in China’s Keqiao district, Taiwan’s knitting hubs, and Korean specialist mills. Keqiao stands out for low MOQ, vertical integration, and global freight reliability.

Why Source from China’s Keqiao Region?

Keqiao offers:

- Minimum 500m per color MOQ

- Custom stretch satin development within 7–10 days

- Color-matched dyeing with OEKO-TEX and GRS compliance

- Integrated mills offering cutting + packaging for DTC shapewear brands

At Fumao Fabric, we supply nylon/spandex and poly/spandex satins, custom finished with anti-yellowing, anti-bacterial, and laser-cut stabilizing backers.

Explore sourcing hubs via China Textile City official portal.

What About Taiwan or Korean Mills?

For premium shapewear lines, Korean and Taiwanese mills offer fine-denier satin knits with:

- Nano finish

- Cool-touch performance

- Moisture vapor transmission ratings

You can find examples via TTRI (Taiwan Textile Research Institute) and Korea’s KOTRA supplier database.

Conclusion

Stretch satin isn't just for lingerie anymore—it's now the backbone of high-performance, body-contouring shapewear. From ultra-soft control bodysuits to flexible smoothing briefs, the right fabric transforms fit, comfort, and confidence.

At Fumao Fabric, we combine 20+ years of warp-knit experience, CNAS-certified testing, and tailored satin development to help clients build shapewear lines that are both beautiful and functional. Whether you’re launching a startup collection or scaling your shapewear SKUs, we offer tested stretch satin solutions you can trust.

To begin sourcing premium stretch satin for your shapewear range, reach out to our Business Director Elaine at elaine@fumaoclothing.com. We’re here to help you shape success—seamlessly and stylishly.