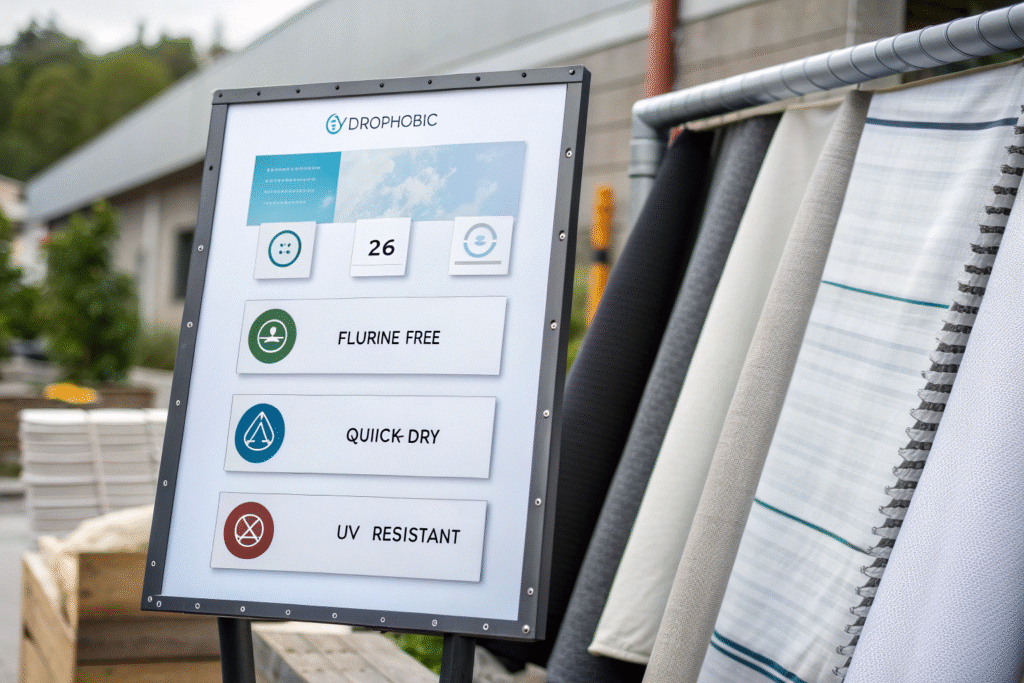

From surfing in the Pacific to lounging poolside in Miami, beachwear must dry fast, stay light, and resist sticking to the skin. That’s where hydrophobic finishes come into play. These invisible coatings repel water on contact—keeping garments light, breathable, and more comfortable even after full immersion.

Hydrophobic finishes for beachwear are chemical treatments applied to fabrics that cause water to bead up and roll off rather than soak in. The best finishes strike a balance between fast drying, breathability, eco-safety, and durability through sun, salt, and wash cycles.

At Fumao Fabric, we’ve developed and tested hydrophobic finishes across hundreds of swimwear and performance fabric collections. In this article, I’ll walk you through the best options, how they work, and how to choose one that suits your brand’s quick-dry and sustainability goals.

What Makes a Fabric Truly Hydrophobic?

A fabric is considered hydrophobic when its surface tension repels water molecules, preventing absorption. The performance is typically measured by contact angle—how much a water droplet beads up rather than spreads out.

Hydrophobicity is achieved through chemical treatments that reduce surface energy, causing liquids to roll off quickly.

Common Base Fabrics for Beachwear

| Fabric | Natural Hydrophobicity | Suitable for Finish |

|---|---|---|

| Polyester | Moderate | Excellent |

| Nylon | Moderate | Excellent |

| Spandex | Low | Needs blend |

| Recycled PET | Moderate | Finish compatible |

We enhance beachwear performance by applying hydrophobic coatings to lightweight woven or stretch-knit fabrics (usually 120–180 gsm). Our internal tests measure water repellency via AATCC 22 spray test and contact angle goniometry.

What Are the Top Hydrophobic Finishes Used in Beachwear?

There are several hydrophobic treatment families available, each with its own pros and cons depending on use case, sustainability goals, and budget.

The best finishes for quick-dry beachwear maintain repellency under sun, salt, chlorine, and repeated wash cycles.

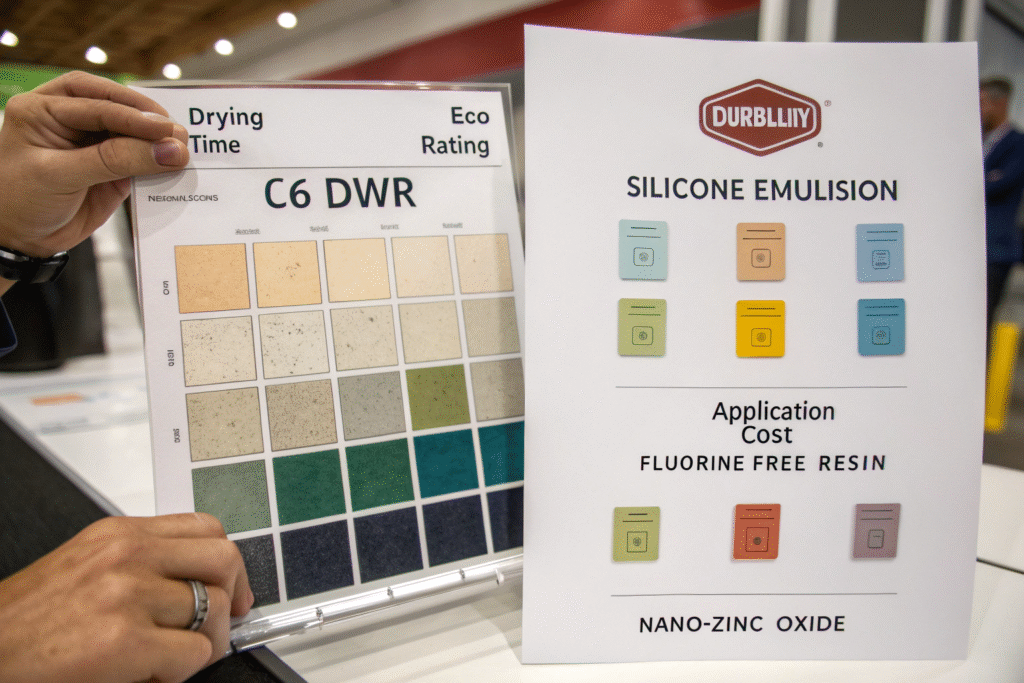

Top Finishes Overview

| Finish Type | Key Features | Eco Profile | Dry Time |

|---|---|---|---|

| C6 DWR (Short-Chain Fluorocarbon) | Excellent repellency, chlorine resistance | Better than C8, not fluorine-free | Fastest (1–2 min) |

| Fluorine-Free Resin | Bio-based, suitable for OEKO-TEX | Fully sustainable | 2–3 min |

| Silicone Emulsion | High softness, good water roll-off | Neutral impact | 2–3 min |

| Nano-Silica or ZnO | UV+water repellent combo | Low toxicity, long-lasting | 2–3.5 min |

Our AquaShield C6 finish remains 90% water-repellent after 20 saltwater washes, and we offer EcoDry FF (fluorine-free) for brands targeting GOTS or bluesign® compliance.

Which to Choose?

- C6 DWR: Best for performance swimwear or surfwear needing extreme repellency

- Fluorine-Free: Ideal for eco-focused fashion beachwear

- Silicone: Great for soft-hand feel and basic water repellency

- Nano ZnO: Excellent for UV+water dual function in tropical resort wear

How Do Hydrophobic Finishes Affect Fabric Feel and Breathability?

A common concern is that hydrophobic treatments might alter the hand feel or trap heat. Advanced finishes now minimize this risk.

Modern hydrophobic finishes bond at the surface level without clogging pores or stiffening fabric—preserving breathability and comfort.

Fabric Feel Comparison (Post Finish)

| Finish | Hand Feel | Breathability Impact | Flexibility |

|---|---|---|---|

| C6 DWR | Smooth, slightly waxy | Minimal | High |

| Fluorine-Free Resin | Natural, soft | Very low impact | High |

| Silicone Emulsion | Silky-soft | Slight airflow reduction | Medium |

| Nano-Coating | Crisp surface | Slightly reduced | Medium–High |

In our FX-HydroLight series, we use low-add-on formulations (<4% solids) to maintain >150 mm/s air permeability, ideal for swim shorts and performance tops.

Where to Source Hydrophobic-Treated Beachwear Fabrics?

Not all “quick-dry” labels guarantee high-performance hydrophobicity. Many rely on fabric type alone without finishing. To ensure real functionality, source fabrics that list spray test scores, contact angle data, and wash durability.

Partner with suppliers offering lab-tested, ready-to-print or dye fabrics already treated with compliant hydrophobic finishes.

What to Ask Your Supplier

- What’s the hydrophobic agent and brand used (C6, FF, etc.)?

- Can you share spray test (AATCC 22) and contact angle results?

- Is the finish chlorine/salt resistant?

- How many washes does the repellency last?

- Is it OEKO-TEX / bluesign® compliant?

At Fumao Fabric, we offer:

- Quick-dry polyester and nylon blends with certified DWR or fluorine-free treatments

- Custom swatchbooks with side-by-side pre- and post-wash test reports

- Low MOQ (300 meters/color) and 48-hour sampling for performance wear brands

- Global shipping with full documentation for U.S. and EU customs

Conclusion

Hydrophobic finishes are essential for next-gen beachwear. Whether you prioritize fast drying, eco-compliance, or sun-sea durability, selecting the right finish can elevate your fabric from functional to premium.

At Fumao Fabric, we offer a curated selection of certified hydrophobic beachwear fabrics—from high-repellency C6 finishes to planet-friendly fluorine-free coatings. With performance data, low MOQs, and customization, we help your swimwear or resort line dry faster and last longer.

To explore our hydrophobic fabric library or request quick-dry swatches, contact our Business Director Elaine at elaine@fumaoclothing.com. Let’s make every drop roll off—in style.