Electrocaloric cooling systems are emerging as an alternative to traditional vapor-compression refrigeration. They promise energy efficiency, compact size, and reduced environmental impact. But while most research focuses on electrocaloric ceramics or polymers, the choice of fabric—used as substrates, encapsulation, or integration layers—plays a critical role in performance and scalability.

The best fabrics for electrocaloric cooling systems are those that combine high dielectric stability, mechanical flexibility, thermal conductivity, and durability under repeated electrical cycling. Fabrics like polyester, nylon, aramid blends, and engineered composites are leading candidates.

The following sections break down how fabrics contribute to electrocaloric cooling performance and which materials are most suitable.

Why Does Fabric Choice Matter in Electrocaloric Cooling?

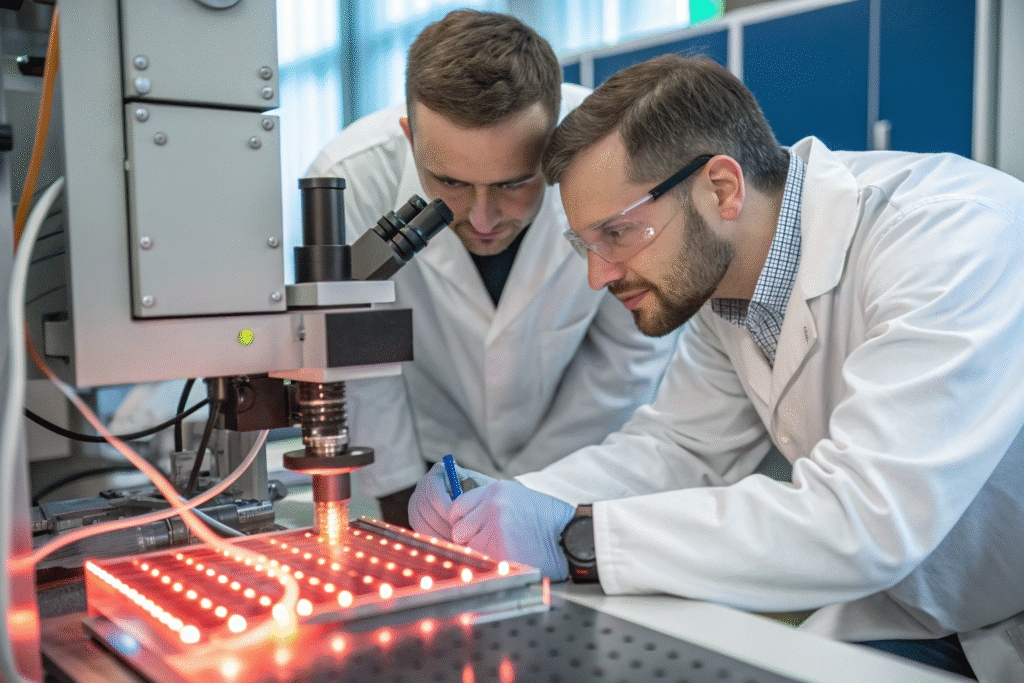

Electrocaloric devices operate by applying an electric field to a dielectric material, causing it to heat or cool. In practical applications, fabrics can serve as structural layers, flexible carriers, or thermal management aids. Poor fabric selection can lead to dielectric breakdown, heat losses, or mechanical fatigue.

The right fabric provides both insulation and stability, ensuring long-term operation without degrading under stress.

How Do Fabrics Affect Dielectric Strength?

Dielectric strength is crucial because electrocaloric cooling depends on electric fields. Fabrics such as polyester and nylon have excellent insulating properties. They withstand high voltages and are widely available at industrial scale.

On the other hand, natural fibers like cotton or linen absorb moisture, which reduces dielectric performance. This makes them less reliable unless treated with polymer coatings.

Which Fabrics Improve Thermal Conductivity?

Electrocaloric cooling systems require efficient heat transfer. Fabrics reinforced with aramid fibers or integrated with graphene composites show promise. These materials conduct heat more effectively, enabling faster cooling cycles.

A hybrid approach—polyester base with graphene-infused coatings—balances flexibility and conductivity.

What Synthetic Fabrics Work Best for Electrocaloric Devices?

Synthetic fabrics dominate electrocaloric research because they are consistent, flexible, and scalable.

Polyester, nylon, and aramid-based fabrics are the top choices due to their dielectric strength, durability, and adaptability for composite coatings.

Why Is Polyester Widely Used?

Polyester fabrics are cost-effective, moisture-resistant, and easy to coat with functional films. Their low water absorption helps preserve dielectric stability.

They are already used in capacitors and insulation layers, which aligns with electrocaloric applications.

Can Aramid Fabrics Enhance Durability?

Aramid fabrics like Kevlar® and Nomex® withstand high temperatures and mechanical stress. They prevent breakdown during high-voltage cycles.

While more expensive, they are ideal for long-term and high-performance electrocaloric devices. Adding thin ceramic coatings further enhances performance.

Are Natural Fabrics Suitable for Electrocaloric Applications?

Natural fabrics are not typically preferred, but with treatments, they can be viable.

Cotton, silk, and linen can be engineered with coatings to provide insulation and stability, but they remain secondary to synthetics.

Can Cotton Be Modified for Electrocaloric Use?

Cotton absorbs water, which reduces dielectric properties. However, applying polyurethane coatings or embedding nano-ceramics can transform cotton into a functional substrate.

Its breathability may also aid comfort in wearable cooling systems.

Is Silk a Viable Alternative?

Silk fibers are strong, lightweight, and have moderate dielectric stability. With coatings, they can act as flexible carriers for thin-film electrocaloric layers.

However, silk is costly and less scalable than polyester or nylon, limiting its role in large-scale systems.

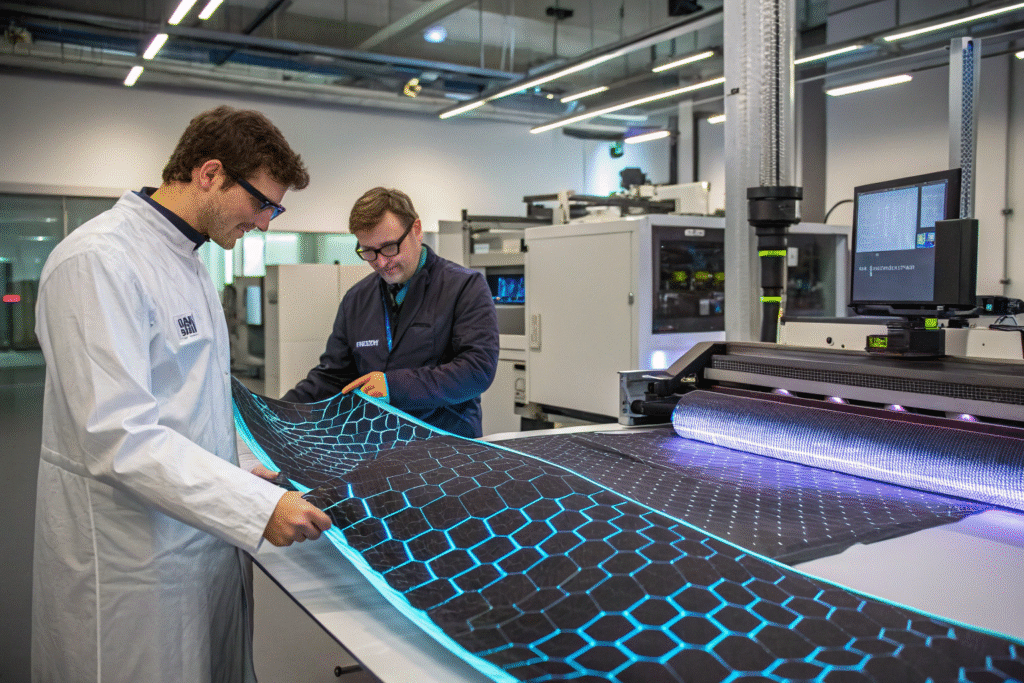

What Advanced Fabric Composites Are Emerging?

Beyond natural and synthetic fabrics, engineered composites are paving the way.

Graphene-coated fabrics, ceramic-polymer composites, and multilayer laminates provide the balance of flexibility, conductivity, and insulation needed for next-generation cooling.

How Do Graphene-Fabric Composites Perform?

Graphene-coated fabrics enhance both conductivity and durability. They support fast charge-discharge cycles, which improve cooling performance.

These fabrics are also lightweight, making them suitable for wearable electronics.

Why Are Ceramic-Fabric Laminates Important?

Ceramic-polymer laminates on fabrics combine high dielectric constants with flexibility. Studies in Applied Materials show that barium titanate coatings on polyester create robust electrocaloric layers.

This approach offers the best balance of cost, scalability, and performance.

Conclusion

The best fabrics for electrocaloric cooling systems are synthetic-based fabrics (polyester, nylon, aramid) enhanced with advanced coatings or composites. Natural fabrics can be modified but remain secondary in performance and scalability. Future research will likely focus on graphene composites and ceramic laminates for wearable and industrial applications.

If you are interested in sourcing or developing advanced technical fabrics for electrocaloric cooling or other high-performance applications, Shanghai Fumao can be your trusted partner. Reach out to our Business Director Elaine at elaine@fumaoclothing.com to explore collaboration opportunities.