For years, my clients in the US and EU have asked me one recurring question: "Are your fabrics safe and compliant?" This often leads to a deep discussion about dyes, specifically azo-free dyes. If you're importing textiles, you've likely heard this term. But what does it truly mean for your business?

Azo-free dyes are synthetic colorants that do not contain any of the restricted azo compounds known to release carcinogenic aromatic amines. They matter because using non-compliant dyes can lead to severe legal, financial, and reputational damage. For brands and buyers, azo-free is not just a trend; it's a non-negotiable standard for market access and consumer safety. At Fumao Textiles, our CNAS-accredited lab ensures every batch of fabric meets this critical requirement, giving you peace of mind.

Let's dive deeper into the world of azo-free dyes. We will explore their definition, the risks of non-compliance, the benefits of switching, and how to verify your supplier's claims. This knowledge is essential for making informed, responsible sourcing decisions.

What are azo-free dyes?

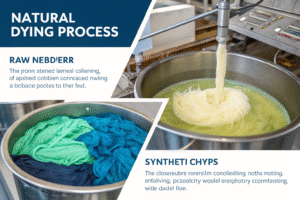

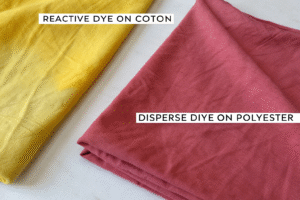

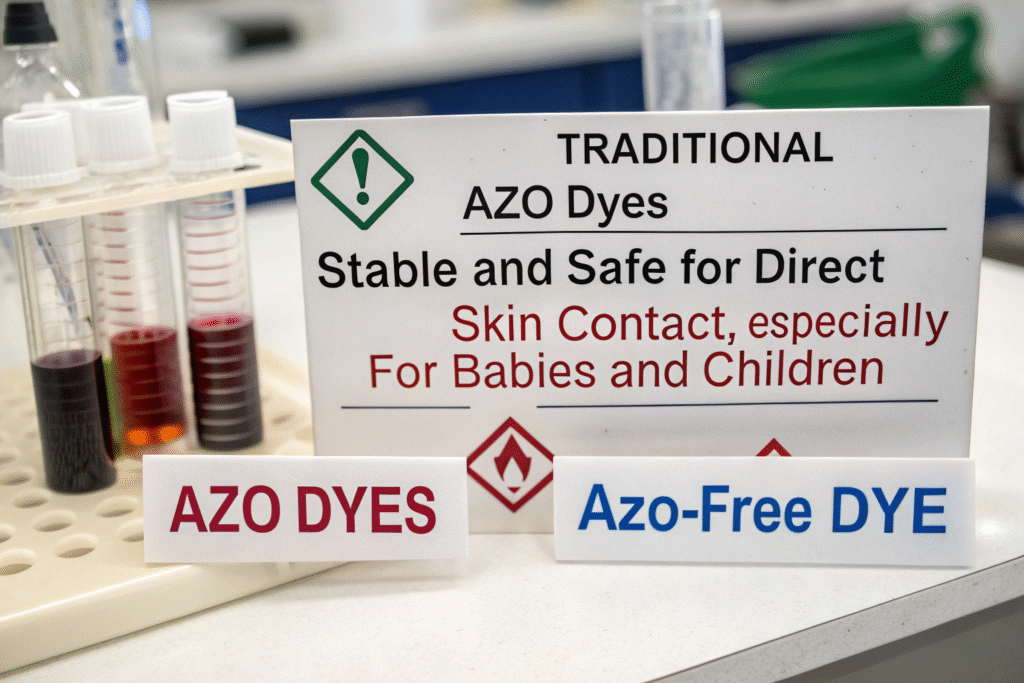

When we talk about dyes in our Keqiao factory, clarity is key. Azo dyes are a large class of synthetic dyes, valued for their color fastness and vivid hues. The problem isn't all azo dyes, but a specific subgroup. Azo-free dyes are precisely defined: they are colorants completely free from any azo compounds that can split under certain conditions to form any of the two dozen-plus aromatic amines classified as carcinogenic by regulations like REACH.

The key difference lies in their chemical structure and safety. Traditional azo dyes can break down and release these harmful amines, which can be absorbed through the skin. Azo-free dyes are chemically engineered to be stable and cannot release these banned substances. This makes them safe for direct and prolonged skin contact, which is why they are mandatory for apparel, especially for babies and children.

How do azo-free dyes differ from conventional dyes?

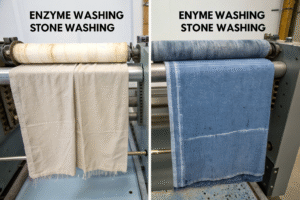

The core difference is safety and compliance. While both can provide excellent color, conventional azo dyes carry a hidden risk. The banned aromatic amines are classified as carcinogens. Azo-free dyes are formulated to eliminate this risk entirely. In terms of performance, modern azo-free dyes have advanced tremendously. They now offer a wide color gamut, good color fastness to washing, and excellent lightfastness, rivaling their conventional counterparts. The global push for safe and sustainable textiles has driven this innovation, making azo-free a viable and superior choice.

Are all azo dyes banned in textile production?

This is a critical misunderstanding. Not all azo dyes are banned. The prohibition, under regulations like EU REACH, applies specifically to those azo dyes that can cleave to form any of the 22+ listed aromatic amines. Many azo dyes that do not produce these specific amines are still legally and widely used in the textile industry. However, the safest and most future-proof strategy, which we advocate at Fumao, is to use azo-free dyes for all sensitive applications. This ensures full compliance and builds brand trust. You can find a definitive list of these restricted amines on the EU REACH legislation portal.

What are the risks of non-compliant dyes?

Ignoring the azo-free standard is one of the costliest mistakes an importer can make. The risks extend far beyond a simple production error. They threaten the very viability of your business in major markets like Europe and North America. The consequences are legal, financial, and reputational.

The most immediate risk is legal action. Customs authorities in the EU and US actively test imported textiles. If your shipment is found to contain banned azo dyes, the entire consignment can be seized and destroyed at your cost. You may also face hefty fines and penalties from regulatory bodies. In severe cases, it can lead to a ban on your products, shutting you out of the market entirely. This legal framework is designed to protect consumers, and there is zero tolerance for non-compliance.

Can non-compliant dyes lead to legal penalties?

Absolutely. The legal penalties are severe and enforceable. Under EU regulations, member states are required to ensure products containing these banned amines are withdrawn from the market. This isn't a theoretical risk. There are numerous RAPEX notifications (the EU's rapid alert system for dangerous non-food products) specifically for textiles containing banned azo dyes. The financial impact is twofold: you lose the entire value of the seized goods, and you pay the fines. This can be a death blow for small and medium-sized businesses. Furthermore, your company name may be listed in public compliance databases, causing irreparable brand damage.

How do harmful dyes affect brand reputation?

In the age of social media, a compliance scandal can destroy a brand overnight. Consumers are more informed and conscious about product safety than ever before. If your brand is linked to carcinogenic chemicals in clothing, the public backlash is swift and brutal. Trust, once lost, is incredibly difficult to regain. We've seen brands lose major retail partnerships and face devastating PR crises. Using azo-free dyes from a certified supplier like Fumao is not just a compliance step; it's a core part of your corporate social responsibility strategy. It protects your brand's image and demonstrates a commitment to customer safety.

Why switch to azo-free dyed fabrics?

Making the switch to azo-free is often seen as a compliance cost. I urge you to see it as a strategic investment. The benefits directly translate into a stronger market position, reduced risk, and alignment with the values of the modern consumer. It's a decision that pays for itself.

The most significant benefit is guaranteed market access. By sourcing azo-free fabrics from the start, you eliminate the risk of customs rejection. This ensures smooth logistics and reliable delivery schedules to your customers. Secondly, it future-proofs your business. Environmental and safety regulations are only getting stricter. By adopting azo-free standards now, you stay ahead of the curve and avoid costly re-engineering of your supply chain later.

Does using azo-free dyes improve market access?

Without a doubt. Using azo-free dyes is your passport to the European and North American markets. It is the baseline requirement. When you can provide proof of compliance, such as a valid OEKO-TEX STANDARD 100 certificate, you streamline the customs process. This proof builds immediate trust with distributors and retailers who require these certifications. It opens doors to partnerships with premium brands that have zero-tolerance policies for non-compliant materials.

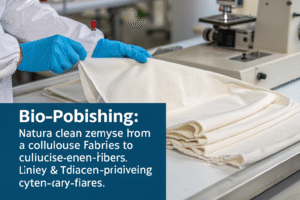

Are azo-free fabrics more sustainable?

While "azo-free" specifically addresses safety, it often aligns with broader sustainability goals. The chemical processes for modern azo-free dyes are frequently designed to be more environmentally friendly, with better wastewater management. Furthermore, this commitment to safety is often part of a larger eco-friendly package. For instance, our azo-free dyeing processes are integrated into our wider green manufacturing initiatives, including water recycling and energy reduction. This allows you to market your products not only as safe but as responsibly made, a powerful message for today's eco-conscious shoppers.

How to verify azo-free dye compliance?

Trust is good, but verification is essential. You cannot simply take a supplier's word for it. As a business owner, you need a robust system to verify compliance. This protects you and ensures the integrity of your products. At Fumao, we have built transparency into our process.

Verification starts with demanding independent, third-party lab certificates. Reputable suppliers will have these documents readily available. Look for certificates from internationally recognized bodies like SGS, ITS, or specifically the OEKO-TEX STANDARD 100 certification, which tests for banned azo dyes. Always check the scope and validity of the certificate to ensure it covers the specific fabric you are purchasing.

What certifications should I look for?

| The most recognized and trusted certification for this purpose is the OEKO-TEX STANDARD 100. This label certifies that every component of the fabric, from the threads to the dyes, has been tested for harmful substances. Other key certifications to look for include: | Certification | Focus Area | Relevance to Azo-Dyes |

|---|---|---|---|

| OEKO-TEX STANDARD 100 | Harmful substances in textiles | Directly tests for banned azo dyes | |

| GOTS (Global Organic Textile Standard) | Organic fibers and environmental criteria | Prohibits the use of banned azo dyes as part of its criteria | |

| BLUESIGN® | Environmental and workplace safety in manufacturing | Restricts the use of hazardous chemicals, including banned azo dyes |

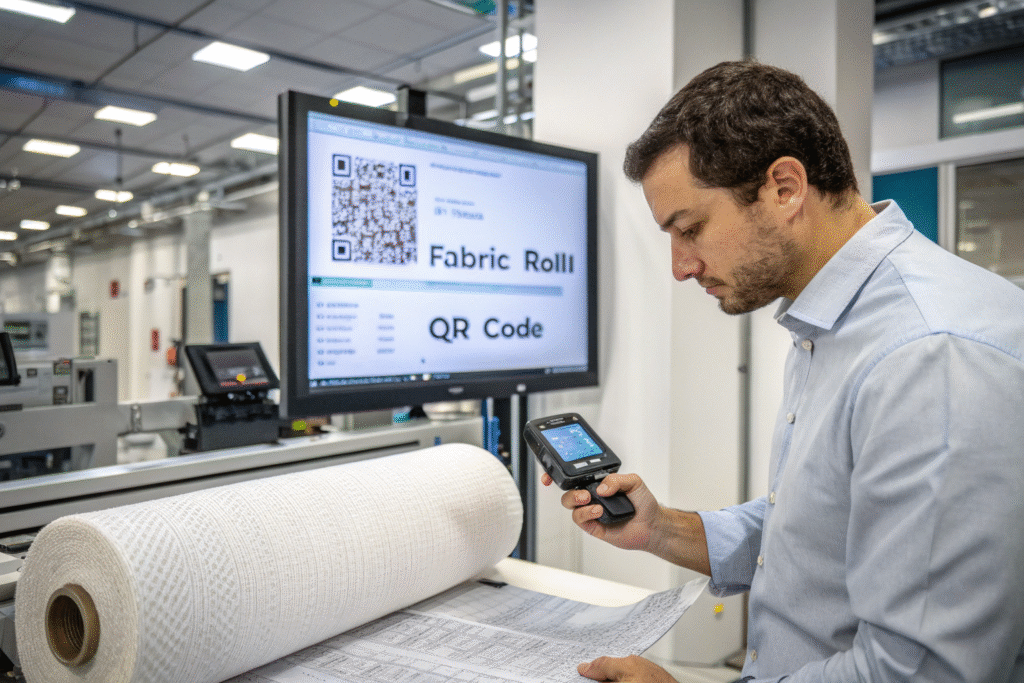

Beyond certificates, ask your supplier about their in-house testing capabilities. Our CNAS-accredited lab, for example, conducts batch testing, and we provide a unique QR code for traceability.

Can I trace the dyeing process for my order?

Yes, with the right supplier. Advanced suppliers have moved beyond paper trails. We use a digital tracking system. Each of our fabric rolls has a QR code. When you scan it, you get real-time access to the fabric's life cycle, including the dyeing batch details and the corresponding test reports from our lab. This level of supply chain transparency is no longer a luxury; it's what discerning buyers like you should expect. It empowers you to make informed decisions and provide proof to your own customers.

Conclusion

Navigating the complex world of textile compliance doesn't have to be a burden. Understanding azo-free dyes—what they are, the risks of ignoring them, their tangible benefits, and how to verify them—is your first line of defense. It transforms a potential vulnerability into a solid competitive advantage. Choosing azo-free is a direct investment in your product's safety, your brand's integrity, and your customers' trust. It ensures smooth market access and aligns your business with the unstoppable global trend towards responsible and sustainable fashion.

If you are ready to source fabrics that are guaranteed safe, compliant, and high-quality, let's talk. We at Fumao Textiles have built our entire vertical supply chain—from weaving to dyeing to finishing—around these core principles. We can provide the certifications, the traceability, and the peace of mind you need for your next order. For a direct conversation about how we can partner to produce your clothing line with fully compliant fabrics, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's weave success, safely.