The growing demand for eco-friendly apparel has catapulted recycled PET (rPET) into the spotlight—especially rPET sourced from ocean plastic waste. But as brands increasingly promote their sustainability commitments, a critical question emerges:

How can you actually verify that your rPET fabric contains genuine ocean plastic—and not just general recycled PET from post-consumer bottles?

This article provides a comprehensive guide for fashion brands, sourcing managers, and sustainability officers looking to authenticate the origin of their recycled ocean plastic fabrics.

What Certifications Cover Ocean Plastic rPET Claims?

As rPET usage grows, third-party verification is essential. Certifications and chain-of-custody documentation are the cornerstones of trust when sourcing ocean plastic–based textiles.

Which Global Standards Verify Ocean-Sourced rPET?

Two key certification bodies verify recycled content and traceability of marine plastics:

-

Global Recycled Standard (GRS)

Administered by Textile Exchange, GRS certifies that the recycled content meets minimum thresholds and that responsible processing standards are followed. While GRS does not exclusively confirm “ocean” origin, it supports traceability and supplier audits. -

Ocean Bound Plastic (OBP) Certification

Developed by Zero Plastic Oceans, this label specifically addresses plastic collected from coastal areas—considered “at-risk” of ocean entry. OBP certification ensures that materials were sourced within 50km of oceanic boundaries, with collection and transformation traceable.

Both certifications can be combined in your supply chain for added credibility.

Can Brands Trust Plastic Bank, SEAQUAL™, or #tide® Materials?

Yes. Organizations like:

offer verified supply chains and branded materials sourced from marine plastic waste, including fishing gear, bottles, and shore cleanup. They partner with collection hubs and transform plastic waste into textile-grade pellets or yarns, often with their own QR-encoded tracking systems.

These branded systems are ideal for brand storytelling, but be sure your converter or knitting/weaving mill passes on batch-level documentation.

How Is Recycled Ocean Plastic Traced Through the Supply Chain?

True traceability goes beyond a “recycled” claim. Verifying ocean plastic in rPET fabric requires batch-specific documentation and sometimes physical fingerprinting.

What Is Chain of Custody and Why Does It Matter?

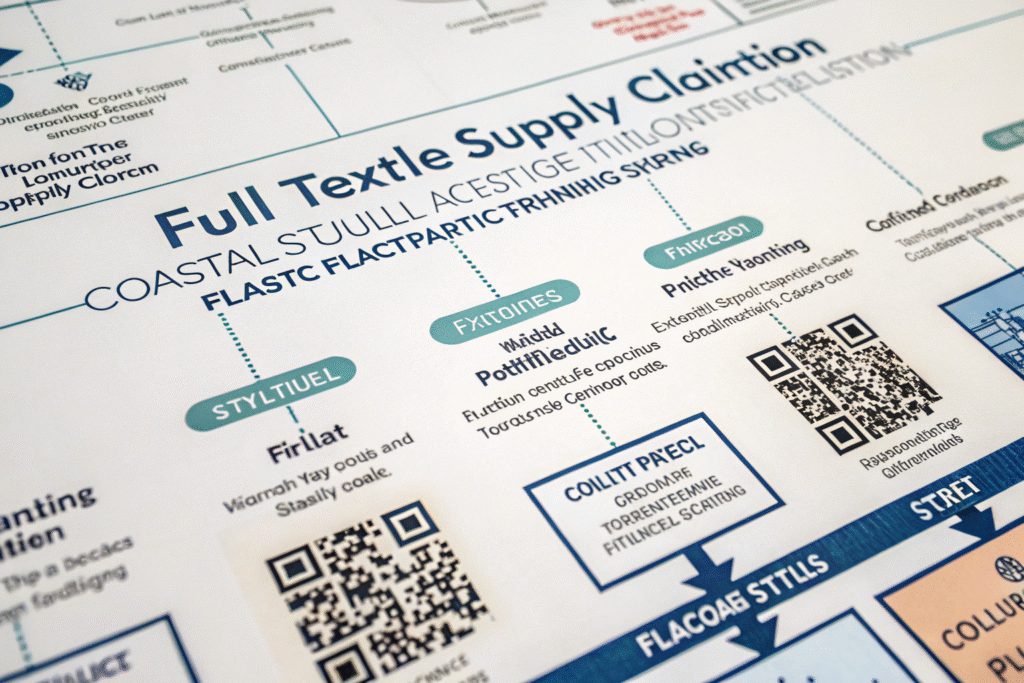

Chain of custody means that each stage—from collection to spinning—is logged, verified, and traceable:

- Collection date and location (e.g., Indonesia, Thailand, Philippines)

- Type of plastic collected (HDPE, PET, etc.)

- Partner recycler or processor ID

- Resin batch numbers

- Yarn lot and fabric roll correlation

This data is often managed using blockchain or traceability software like TextileGenesis™ or BCome, allowing you to view the journey from bottle to bolt.

How Can Fabric Buyers Verify Supply Chain Authenticity?

Ask your supplier or mill for:

- OBP collection certificates

- Resin origin reports (with GPS tagging or documentation)

- GRS Transaction Certificates (TC)

- Internal Quality Control (IQC) documents from yarn suppliers

- Yarn lot numbers linked to fabric batch IDs

Brands like Patagonia and Pangaia have pioneered full traceability by integrating this documentation into their ERP systems and labeling standards.

Are There Lab Tests to Confirm Ocean Plastic vs. General rPET?

Although certification is essential, laboratory testing is becoming more advanced in verifying origin fingerprints in plastics—although it remains complex and expensive.

Which Tests Can Distinguish Marine rPET?

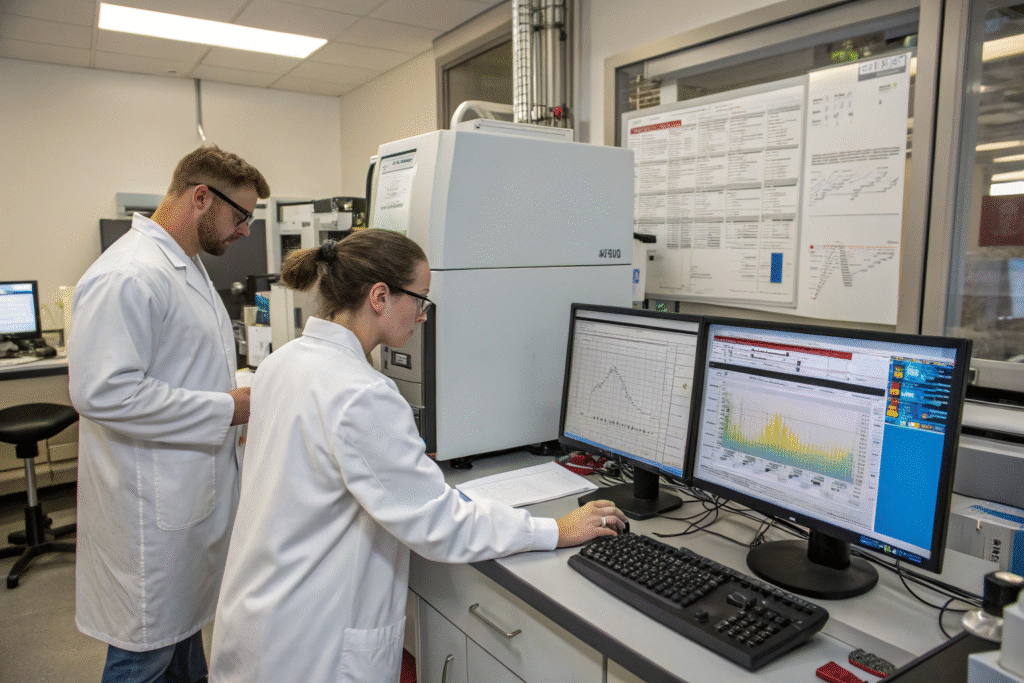

Some labs now offer chemical signature profiling using:

- FTIR (Fourier Transform Infrared Spectroscopy) – Determines polymer purity and additive traces

- DSC (Differential Scanning Calorimetry) – Analyzes thermal behavior, which may vary between sun-degraded ocean PET and post-consumer bottle PET

- Isotope Ratio Mass Spectrometry (IRMS) – Advanced test to analyze elemental isotopic composition

While these methods are not 100% definitive for “ocean” vs. “land” PET, they can flag irregularities or support origin claims when paired with certification documents.

Institutes like Intertek and SGS offer these lab services, especially for compliance-driven buyers.

What Are the Limitations of Current Testing?

- High cost per batch (can exceed $1,000/test)

- Inconclusive without reference samples

- Not scalable for every roll or PO

Thus, lab tests are best used as spot verification in combination with documentary traceability and random supplier audits.

What Are Best Practices for Brands Sourcing rPET from Ocean Waste?

As a brand or sourcing team, your role is to demand transparency, verify certificates, and document supply chain details—especially when marketing sustainability to consumers.

What Questions Should You Ask Your Fabric Mill or Converter?

- Is the yarn OBP or SEAQUAL™ certified?

- Can you provide GRS Transaction Certificates and OBP Origin Reports?

- Do you track batch-level traceability for resin and yarn?

- Is the spinning mill approved by Zero Plastic Oceans or GRS?

- Can I audit the supplier or see digital passports?

Asking these questions up front filters out greenwashing and ensures your rPET claims can hold up under scrutiny—especially in Europe or California.

Can Fumao Fabric Help Source Verified Ocean Plastic rPET?

Yes. At Fumao Fabric, we work with OBP-verified yarn spinners and GRS-certified mills across Fujian and Zhejiang. Our capabilities include:

- Low-MOQ ocean plastic rPET fabric orders (300m–1,000m)

- Full documentation: OBP source report + GRS TC + resin trace logs

- Support with QR-integrated digital passports for brand storytelling

- Lab testing via SGS or CTI for confirmation sampling

Whether you're developing sustainable outerwear, swimwear, or tote bags, we can deliver high-performance, verified rPET textiles with traceability from sea to shelf.

Conclusion

The future of ocean-friendly fashion demands more than just good intentions—it requires verifiable materials, certified supply chains, and documented accountability. Sourcing rPET from ocean plastic waste is a meaningful step, but only if you can back your claim with certifications like OBP, GRS, and auditable data.

At Fumao Fabric, we believe traceability is not optional—it’s the standard. From OBP resin to GRS-certified yarn to finished textile, we help brands ensure every meter of rPET fabric stands up to real-world scrutiny and consumer trust.

📩 To start sourcing verified ocean plastic fabrics with full traceability, contact our Business Director Elaine at elaine@fumaoclothing.com today.