You’ve placed a fabric order. You wait. You wonder: Is it woven yet? Has it passed quality checks? When will it ship? This black box of uncertainty is gone. Supply chain transparency isn't a luxury; it's your right as a buyer to know the story behind every meter of fabric you purchase.

Fumao Fabric's QR Code Tracking System is your direct window into the journey of your textiles. By simply scanning a code, you move from guesswork to guaranteed, real-time visibility. This isn't just about tracking a shipment; it's about verifying quality, validating sustainability claims, and building unshakable trust in your supply chain from yarn to yard.

Let's break down how this technology transforms your sourcing experience from a stressful logistical challenge into a managed, transparent, and collaborative process. We'll show you exactly how to access, interpret, and leverage the data to make smarter, faster decisions for your business.

How to Access and Scan Your Fabric's QR Code?

Accessing your fabric's complete history is as simple as pointing your phone's camera. Every single roll of fabric from Shanghai Fumao comes with a unique, tamper-evident label featuring a QR code and a corresponding alphanumeric tracking ID. This is your passport to transparency.

Here’s the process: Upon shipment, you receive a digital packing list with all roll numbers. When the physical rolls arrive at your facility, use any standard smartphone QR scanner (built into your camera app or a free app) to scan the label. No special software is needed. The code instantly redirects you to a secure, encrypted web portal hosted on our servers. The first scan often triggers a welcome notification to our team, letting us know your goods have arrived safely—a feature our clients in Europe love for confirming receipt without extra emails.

What Data Appears Immediately After Scanning?

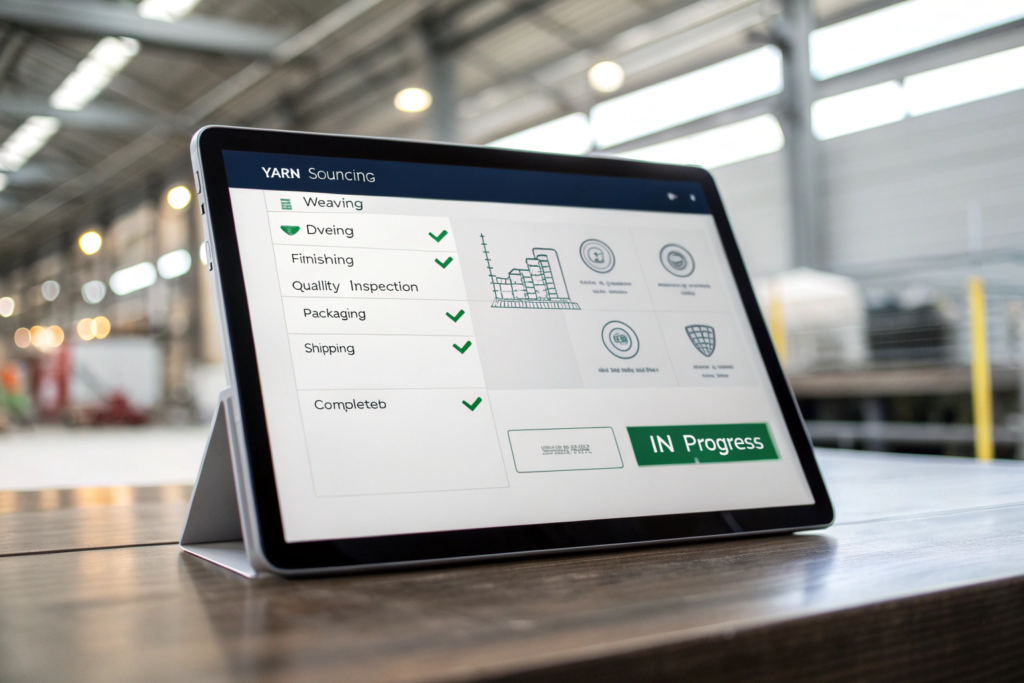

The moment you scan, a dashboard loads on your phone. It’s designed for instant clarity. The top section shows the live status of your fabric roll. Is it "In Production," "Under Inspection," "In Transit," or "Delivered"? Below that, you get the core specifications: Fabric Composition (e.g., 100% GOTS Organic Cotton), Order Number, Color Code, and Batch/Lot Number.

Crucially, you immediately see key quality control indicators. For a performance fabric, this includes pre-loaded test results for colorfastness to washing and rubbing, pilling resistance grade, and dimensional stability. Think of it as a digital birth certificate for that specific roll. For a Swiss client in 2023, this instant access to test data allowed their QC team to approve fabrics for cutting within hours of arrival, bypassing 3-4 days of internal lab testing and accelerating their production by a full week.

Is My Data Secure and Private?

Absolutely. This is a paramount concern. Each QR code is unique and encrypted. The data portal is accessed via a secure HTTPS connection. The information is not publicly searchable; it is only accessible to individuals who have the physical QR code or the unique tracking ID paired with verified credentials. We operate on a need-to-know data-sharing principle.

You own your order data. We do not share your specific purchase information, volumes, or timelines with any other parties. The system is designed for supply chain visibility for brands, not for public display. Our platform complies with major data privacy frameworks, ensuring that your commercial information and the integrity of your supply chain remain confidential and protected.

What Production Stages Can I Track in Real-Time?

Gone are the days of sending "any updates?" emails. Our QR system is updated at critical checkpoints, giving you a live, stage-by-stage view of your fabric's creation. This transforms you from a passive observer into an informed partner.

The tracking covers the entire vertical process we control. You can see when your yarn is received, when weaving begins and is completed, when the greige fabric enters the dyeing or finishing facility, and most importantly, the timestamp and results of every quality inspection. For instance, you'll see entries like: "2024-10-26, 14:30: Fabric passed final inspection on Light Table #3. Minor defect count: 0. Inspector: Zhang."

How Does Tracking Work for Custom Developed Fabrics?

For custom developments, the transparency is even more valuable. From the moment you approve the lab dip, that specific color formula is digitally linked to your order's QR code database. You can track the creation of your bulk production sample (BPS) and see the "Approved" timestamp when you give the green light.

Last year, for a UK-based sustainable brand creating a custom recycled jacquard, the buyer used the portal daily. They watched as their order moved from "yarn dyeing" to "on the loom." When the status updated to "Awaiting BPS Approval," they received an automatic email alert and could cross-reference the physical sample with the production data. This proactive visibility prevented a potential two-week delay in their tightly scheduled production run, as they approved the sample within 24 hours.

Can I See the Actual Quality Inspection Reports?

Yes, and this is the system's most powerful feature. The QR portal doesn't just say "passed inspection." It provides the digitized fabric inspection report. This report, generated from our inspection machines, often includes a defect map—a graphical representation of the fabric roll highlighting the location and type of any minor flaws (e.g., "slub at 22.5 meters").

This allows your cutting room team to plan around imperfections, maximizing fabric yield. As one of our clients from Los Angeles put it: "It's like having X-ray vision before we even unroll the fabric." The portal also stores PDF copies of formal third-party test reports from SGS or ITS for textiles, which you can download and use for your own compliance filings. All documents are stored permanently under your order history.

How to Use QR Data for Sustainability Verification?

In an era of greenwashing, claims need proof. Our QR code system is built to provide verifiable, chain-of-custody evidence for every sustainability attribute we claim.

When you source a fabric like our GOTS Certified Organic Cotton Poplin or Recycled Polyester Satin, scanning the code does more than show composition. It provides direct links to the certificate numbers and the issuing certification body's public database for verification. For recycled materials, you can see the percentage of post-consumer waste (PCR) content and trace it back to the supplier's transaction certificate.

How Do I Verify Certificates Like GOTS or RCS?

The system automates verification. For certified fabrics, the QR dashboard includes a dedicated "Certifications" tab. Clicking on, for example, the "GOTS" badge will expand to show the certificate number, validity period, and the name of the certified entity (e.g., Fumao's dyeing partner). A "Verify" button often links directly to the online database of the certification body (like Control Union or OCS), where you can independently confirm the certificate's active status.

This level of ease is critical. A Danish client sourcing RCS (Recycled Claim Standard) certified fabrics for a major retailer's private label used our QR reports to seamlessly pass their own stringent ethical audit. The auditor simply scanned a roll on-site and had all the verified proof in seconds, turning a typically day-long document review into a 15-minute process.

Can I Access Carbon Footprint or Water Usage Data?

We are progressively integrating this. For our core eco-product lines, the QR portal now includes an Environmental Data section. This presents key metrics from our lifecycle assessments (LCAs), such as the estimated carbon footprint (kg CO2e per kg of fabric) and water consumption compared to industry averages for conventional equivalents.

For instance, a scan of our BAMSILK (bamboo) blend shows: "Water Saved: 65% vs. Conventional Cotton." This isn't just a marketing stat; it's backed by data from our production logs. This allows your brand to make accurate environmental claims in marketing and reporting, moving from vague "eco-friendly" statements to specific, data-driven storytelling that resonates with conscious consumers.

How Does This System Solve Common Buyer Pain Points?

This technology isn't tech for tech's sake. It's a direct solution to the most frequent and frustrating problems you face when importing fabrics: uncertainty, delay, and risk.

Imagine eliminating 50% of your status-check emails. Picture cutting your internal QC time in half. Envision having all the documentation you need for customs or a retailer's audit at your fingertips instantly. That's the practical power of full transparency.

Does It Help with Customs Clearance and Compliance?

Immeasurably. The QR portal serves as a digital technical file. When your freight forwarder or customs broker needs information on composition, weight, or value, you can grant them limited access to the specific roll's data or download the comprehensive report. All the data required for accurate HS code classification is there.

More importantly, for enforcing regions like the EU with upcoming Due Diligence laws, the system provides an auditable trail. You can demonstrate exactly where your fabric came from, who made it, and under what conditions. This turns compliance from a frantic paperwork scramble into a simple, organized digital process managed by Shanghai Fumao on your behalf.

Can It Prevent Disputes and Ensure Accurate Invoicing?

Absolutely. Transparency prevents misunderstandings. The system records the exact finished meterage per roll after final inspection, not just the theoretical length ordered. Your commercial invoice from us is based on this actual shipped quantity, which you can verify against the data in the portal before payment.

This ended a chronic issue for a Canadian client. Previously, they would receive rolls slightly shorter than ordered, leading to complex pro-rata calculations and disputes. Now, they see the exact, verified length in the portal (e.g., "Roll #F045: 102.7m") and their invoice matches it perfectly. Disputes have dropped to zero, and their financial planning is more accurate.

Conclusion

Fumao Fabric's QR Code Tracking System is more than a tool; it's a fundamental shift in the buyer-supplier relationship. It replaces opacity with clarity, anxiety with assurance, and claims with credible, verifiable proof. It empowers you to manage your supply chain proactively, ensure quality and compliance effortlessly, and tell your product's story with authentic confidence.

In today's market, transparency is the ultimate currency of trust. This system delivers that currency directly into your hands, one scan at a time.

Ready to see the difference transparency makes? Experience the confidence of knowing the full story behind your fabrics. Shanghai Fumao is committed to pioneering solutions that make your sourcing smarter, safer, and simpler. To discuss how our QR tracking and integrated vertical supply chain can benefit your next project, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's build a clearer, more reliable supply chain together.