The demand for quantum-ready materials is rising quickly, yet sourcing fabrics that can support such advanced applications remains a significant challenge. Traditional textiles lack the electronic and spintronic behaviors required for quantum devices. Buyers, researchers, and engineers often face a major barrier: suppliers advertise “smart fabrics” but cannot provide verifiable data on topological insulator (TI) performance. Without such validation, investments in wearable quantum systems, spintronics, and high-performance energy harvesting are at risk.

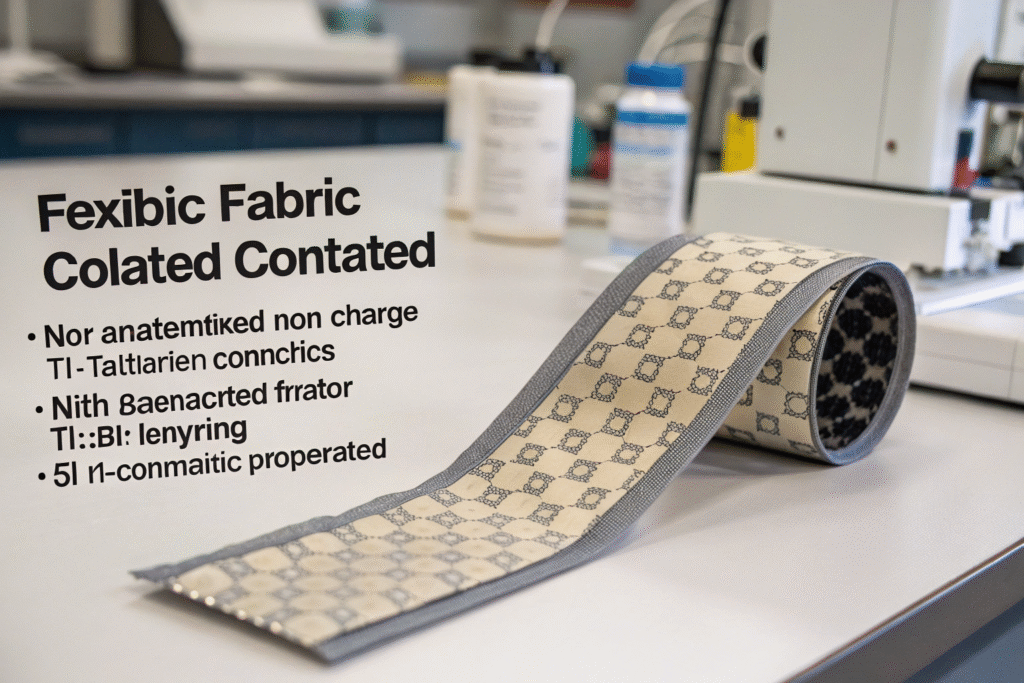

Topological insulator textiles solve this gap by embedding TI nanomaterials like Bi₂Te₃, Bi₂Se₃, or Sb₂Te₃ into fibers or coatings. These fabrics remain flexible yet demonstrate surface conductivity, quantum edge states, and long charge retention. Though still experimental, TI textiles are emerging in prototypes for sensors, nanogenerators, and quantum-compatible fabrics.

This article explains what TI textiles are, the research behind them, sourcing channels, and how to evaluate their performance.

What Are Topological Insulator Textiles?

Topological insulators are materials that conduct electricity on the surface while remaining insulating in the bulk. Integrating these into textiles creates fabrics that are soft yet electronically active.

By coating fibers with TI nanoparticles or embedding TI layers, researchers have demonstrated fabrics that retain flexibility while offering non-contact charge transfer and quantum-compatible surface states.

Why Are They Unique?

- Combine mechanical flexibility with quantum-level electrical properties

- Enable spintronic and optoelectronic applications in wearable devices

- Support long-term charge storage and energy harvesting

- Survive stretching, bending, and mechanical strain without losing conductivity

For example, researchers demonstrated a TI nanocomposite-coated fabric that generated voltages of over 400 V and retained charges for more than 5,000 minutes (X-Mol).

Key Materials in Use

- Bismuth telluride (Bi₂Te₃)

- Bismuth selenide (Bi₂Se₃)

- Antimony telluride (Sb₂Te₃)

- Graphene-assisted composites for enhanced charge mobility

What Research and Prototypes Are Emerging?

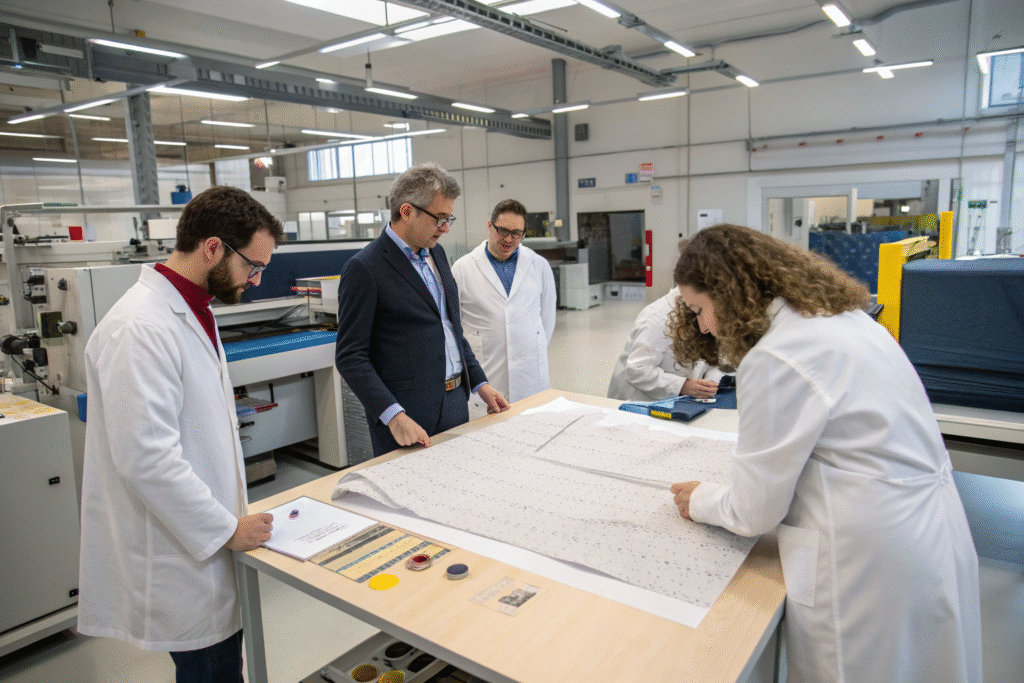

Global research groups are exploring how TI materials interact with flexible substrates. The results show promising durability and energy performance.

Recent studies illustrate the potential of TI nanocomposites to create wearable devices that combine comfort with advanced electronics.

Examples from Recent Studies

- Nanocomposite Fabrics: Coated with Bi₂Te₃-based materials, showing excellent charge retention and energy harvesting capabilities (ScienceDirect).

- Functional Composites: SYCORE-TEX develops porous composites that act as carriers for TI coatings, supporting high-performance integration (Functional Textiles Shanghai).

- Hybrid Nanostructures: Combining TI coatings with graphene-based fabrics for enhanced conductivity and flexibility.

Why This Matters

These results confirm that TI properties can survive textile processing. Fabrics can stretch and bend while still showing advanced electronic behavior, opening doors for wearable quantum systems.

Where Can You Source TI Textiles?

Since TI textiles are still at the research frontier, sourcing requires strategic collaboration between academia, nanomaterial suppliers, and specialized textile firms.

Potential suppliers exist across research institutions, nanomaterial companies, and functional textile manufacturers.

Key Channels

- University Labs: Teams working on TI-textile prototypes often share samples and collaborate with industry.

- Nanomaterial Producers: Suppliers of Bi₂Te₃ and Bi₂Se₃ nanopowders that can be integrated into coatings.

- Advanced Textile Firms: Companies like SYCORE-TEX specialize in coated and composite fabrics adaptable to TI integration.

How to Approach Suppliers

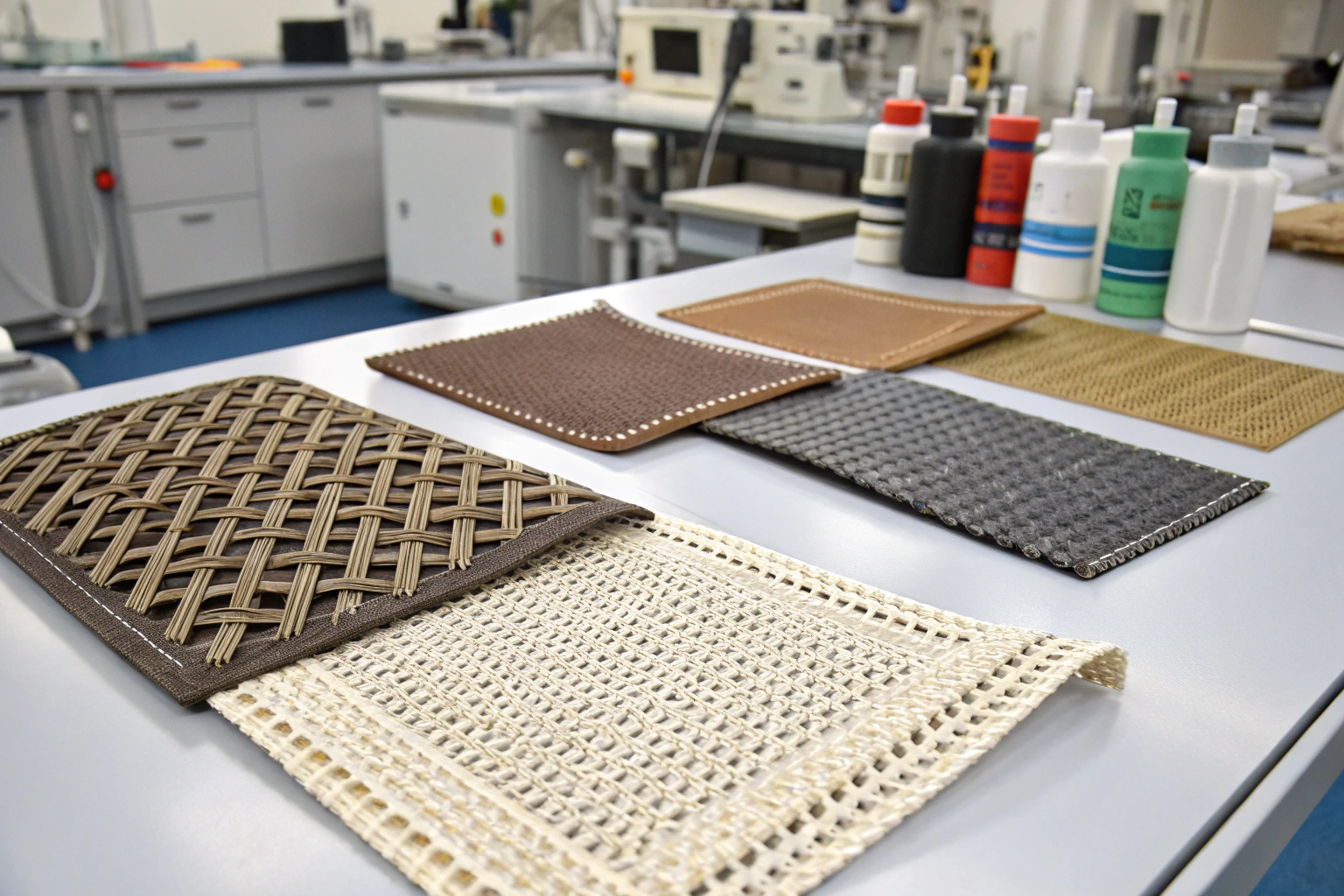

- Request sample swatches with TI coatings for preliminary testing

- Ask for material safety and technical data sheets

- Verify their experience with deposition methods such as sputtering, ALD, or nanocomposite dip-coating

How Should Buyers Evaluate TI Fabric Suppliers?

Suppliers often claim “smart fabric” capabilities without demonstrating TI behavior. Buyers must demand strict evaluation protocols.

Testing should confirm both electrical performance and durability.

Essential Evaluation Criteria

- Electrical Properties: Conductivity vs. bulk insulation, Hall effect, surface mobility.

- Durability: Performance under washing, abrasion, UV exposure, and bending.

- Scalability: Ability to move from lab samples to fabric yardage.

- Integration Readiness: Compatibility with electrodes, encapsulation, or device packaging.

Independent labs such as SGS and Intertek can confirm durability and electrical behavior.

Why Testing Is Non-Negotiable

Without standardized test data, TI fabrics cannot be trusted for quantum use. Certification builds confidence and supports long-term partnerships.

Conclusion

Topological insulator textiles mark a shift from passive fabrics to quantum-capable materials. They combine flexibility with quantum-level surface conduction, enabling spintronic sensors, energy harvesters, and wearable quantum devices.

Though sourcing remains tied to research labs and specialized suppliers, buyers can begin by partnering with nanomaterial providers, functional textile firms, and accredited testing labs. Clear evaluation standards—electrical performance, durability, and scalability—will ensure successful integration into high-value applications.

For companies seeking TI textiles, Shanghai Fumao offers expertise in advanced coatings and collaborative R&D. To explore pilot projects or custom textile development, contact our Business Director Elaine at elaine@fumaoclothing.com for technical discussions and sourcing solutions.