In today’s fast-changing global supply chain, many buyers struggle to find high-performance textiles for emergency relief, military, and outdoor shelters. The pain point is clear: most suppliers either lack durability testing, cannot meet international safety standards, or fail to provide consistent delivery schedules. These challenges leave procurement managers exposed to costly risks.

The answer lies in choosing textile manufacturers that not only provide innovative materials but also integrate full quality control, rapid development, and certified safety standards. By sourcing from trusted suppliers in textile hubs like Keqiao, China, buyers can secure both resilience and reliability for inflatable shelter projects.

As someone who has spent years in the textile manufacturing and export industry, I know that sourcing the right self-deploying shelter fabrics is about much more than price. It is about finding partners who can balance performance, sustainability, and global logistics. Let’s look deeper into how you can approach this procurement process.

What Are Inflatable Shelter Textiles Made Of?

The first question every buyer asks is about the composition of these textiles. Inflatable shelters require technical fabrics that can handle extreme conditions, yet remain lightweight and packable.

Inflatable shelter textiles are usually made of coated or laminated fabrics—such as polyester or nylon reinforced with PU or PVC layers—that provide waterproofing, UV resistance, and air retention capacity.

Why Do Manufacturers Use Laminated Fabrics?

Laminated fabrics combine a base textile (such as high-tenacity polyester) with a polymer layer like TPU or PVC. This enhances water resistance and airtightness. Buyers often look for TPU coatings because they are more eco-friendly compared to PVC. Another option is PVC-coated polyester , which is widely used for cost-sensitive projects, though it is heavier.

Which Properties Are Critical for Durability?

For shelters that must withstand storms or military field conditions, tear strength, flame retardancy, and temperature stability are essential. International buyers often ask for NFPA 701 fire safety certification and ISO 13934-1 tensile testing reports before approving bulk orders.

Where to Find Reliable Shelter Textile Suppliers?

Many companies get lost between middlemen and unverified factories, which creates long lead times and unpredictable quality.

The most reliable sourcing strategy is to work directly with integrated textile clusters like Keqiao in China, where weaving, coating, and inspection facilities are concentrated in one place.

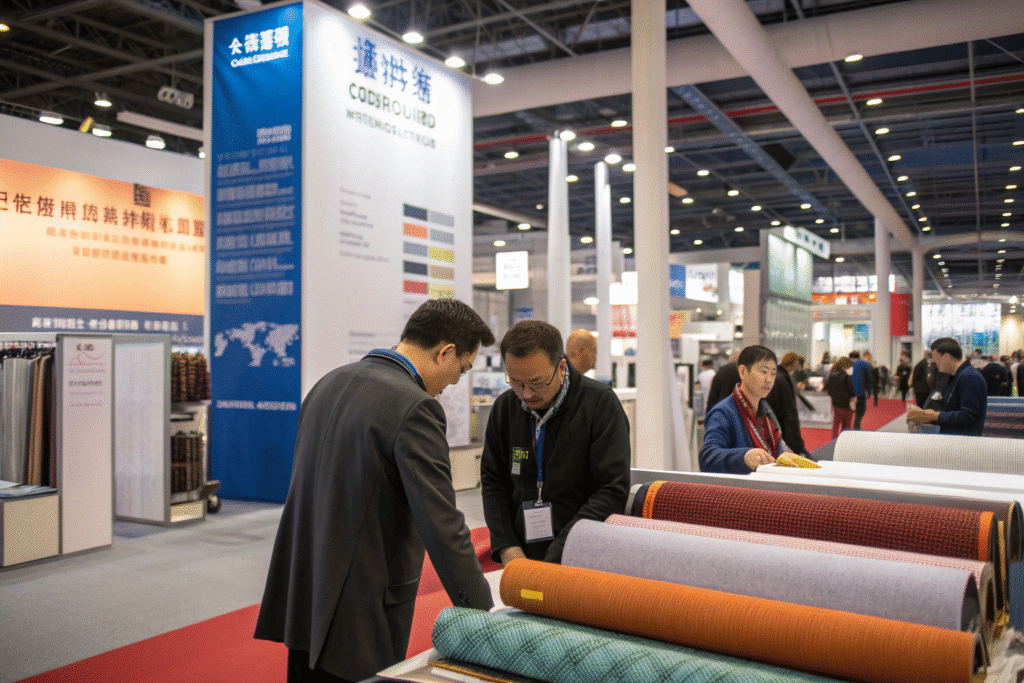

Are Trade Shows Still Useful for Sourcing?

Yes. Events like Techtextil in Germany or the China Keqiao Textile Expo attract both large and niche suppliers. Buyers can meet face-to-face, inspect fabric samples, and request real-time testing.

Can Online Sourcing Platforms Be Trusted?

Platforms like Alibaba or Global Sources are convenient, but buyers should verify certifications and conduct video factory audits. The safest option is to combine online research with physical trade fair visits.

How to Ensure Quality Control in Shelter Fabrics?

A common frustration for American and European buyers is inconsistency—sample fabrics perform well, but bulk shipments do not.

The solution is to partner with suppliers who operate CNAS-accredited testing centers and provide QR-code tracking for each batch of fabric, ensuring consistent compliance with SGS and ITS standards.

What Tests Should Be Mandatory Before Shipping?

Every inflatable shelter textile should undergo:

- Hydrostatic pressure testing

- Tear and tensile strength testing

- Flame retardancy checks

- Colorfastness evaluation

For reference, the SGS textile testing services are widely recognized, and buyers often require official test reports before making payments.

How Can Digital Tools Improve QC?

Some suppliers now offer live dashboards where buyers can track testing results and production progress. For example, QR fabric traceability ensures buyers know the exact composition and test records of each shipment, minimizing risks of disputes.

What Logistics and Costs Should Buyers Expect?

Even with the right fabrics, global buyers often face shipment delays, hidden costs, and tariff issues.

To reduce risks, buyers should source from suppliers with multimodal logistics networks and financial backing to handle large-scale exports.

How Do Tariffs Affect U.S. Buyers?

U.S. importers must consider Section 301 tariffs on certain textiles. Some suppliers mitigate this by routing goods through RCEP member countries or by providing bonded warehouse storage. The USTR tariff schedule is the key reference point.

Which Shipping Options Are the Most Reliable?

For emergency relief orders, air freight ensures speed, though it is costly. For bulk commercial projects, sea freight consolidation offers the best balance between cost and reliability. Many suppliers in Keqiao use Yiwu and Ningbo ports, which are highly efficient.

Conclusion

Sourcing self-deploying inflatable shelter textiles is not just about finding a material—it is about building a reliable partnership with a supplier who offers durability, certifications, quality control, and global logistics expertise. Buyers who combine trade fair visits, digital QC tools, and direct sourcing from textile clusters will enjoy both reduced risk and faster turnaround.

If you are ready to develop or source your own inflatable shelter textiles, we at Shanghai Fumao can provide complete solutions from weaving and coating to inspection and global delivery. To start your project, please contact our Business Director Elaine at elaine@fumaoclothing.com.