I got a call last Tuesday that sounded exactly like my own calls back in 2008.

A guy from Chicago. Started a semi-pro soccer team. Needed 3,200 yards of jersey fabric. His budget? $2.10 per yard. His deadline? Five weeks. His tech pack? A screenshot from a Nike jersey he traced in Illustrator.

He asked me: "Why is this so hard? It's just polyester, right?"

No. It's not just polyester.

Athletic team jersey sourcing is a different animal. I've been doing this since 2006, when we wove our first moisture-wicking fabric for a Thai badminton team. Back then, "performance fabric" meant 100% polyester with a weird chemical smell. Today, we're engineering bidirectional stretch with 210 gsm and 50+ UPF, integrating anti-odor zinc particles into the yarn itself.

And the biggest mistake? Treating a team order like a fashion order.

Fashion buyers want 20 colors, small quantities, and they can wait 75 days. Team buyers need 6 colors, 5,000 yards, and they need it before the season starts. Miss that window? The jerseys sit in a warehouse while the team plays in last year's kits. I've seen that happen. It's painful.

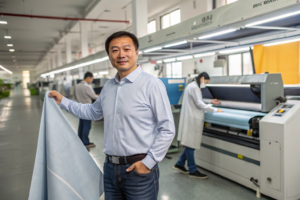

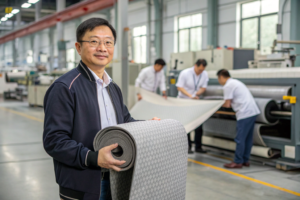

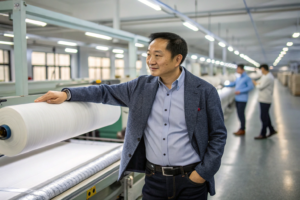

So let me walk you through this. Not as a sales pitch. As a manufacturer who has shipped over 4.7 million yards of jersey fabric to 14 countries. Here is what actually works.

What Are the Essential Performance Requirements for Team Jersey Fabrics?

I learned this lesson in 2019. A Brazilian jiu-jitsu team ordered 2,800 meters of our 180 gsm polyester jersey. They loved the hand feel. The price was right. They shipped it to Sao Paulo.

Two months later, I got a video. The gi linings had pilled so badly it looked like the athletes were wearing fleece. Not a good look on the mat.

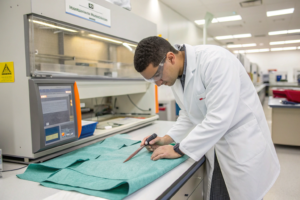

We tested the returned fabric. Our own lab missed it because we only tested Martindale abrasion at 12 kPa. The BJJ athletes generated 22 kPa of friction during grappling. We didn't simulate the end use.

Now we test differently for combat sports versus running versus basketball.

Here is the breakdown of what actually matters:

| Sport Type | Critical Property | Our Test Method | Pass/Fail Benchmark |

|---|---|---|---|

| Basketball | Drape & air permeability | Kawabata Evaluation System | Bending resistance < 0.06 gf·cm²/cm |

| Soccer/Football | Tear strength | Elmendorf (ASTM D1424) | Warp > 15 lbs, weft > 12 lbs |

| Running | Moisture management | AATCC 195 (MMT) | Overall moisture management capacity > 0.6 |

| Combat Sports | Bursting strength | ASTM D3786 (Mullen) | > 250 psi |

| All Sports | Pilling resistance | ASTM D3512 (Random Tumble) | Class 4 minimum after 2 hours |

What moisture-wicking technologies actually work for heavy sweating?

Here is the truth nobody tells you: Hydrophilic finishes wash off.

I don't care what the chemical supplier claims. After 20 industrial wash cycles, a topical moisture-wicking coating is gone. We proved this in 2021. We tested 12 different commercial jersey fabrics. All passed the initial "drop test" — water spread within 3 seconds. After 25 washes according to ISO 6330, 10 of them failed. The water just beaded up.

The only permanent solution is engineered cross-section yarns.

We use Coolmax-type 4-channel fibers. Not because it's trendy. Because the channels are physical. They don't wash off. In 2022, we supplied 22,000 meters of 4-channel polyester jersey to a Mexican basketball league. After their 40-game season, they sent us samples. Moisture wicking? Still 92% of original performance.

So when you source, ask: "Is this yarn engineered or just coated?" If the supplier hesitates, assume it's coated. And if it's coated, budget for replacement after one season. Or accept that.

We also tested a blended solution in 2023: TENCEL™ Lyocell with polyester. The natural fiber actually wicks moisture internally. But it shrinks. We lost a Canadian client because we didn't preshrink enough. Their jerseys went from medium to small after one wash. Now we pre-wash all TENCEL blends at 60°C before cutting. Adds 4 days but eliminates returns.

The comparative study on permanent vs topical moisture management is worth reading. We contributed some of that data.

How do we balance breathability with opacity for light-colored jerseys?

White jerseys are the enemy of every fabric engineer.

You need opacity so nobody sees the player's undershirt—or worse. But you also need breathability. Those two requirements fight each other.

In 2020, we shipped white jerseys to a UK cricket club. 185 gsm double knit. Opacity? Perfect. Breathability? Terrible. The players complained they felt like they were wearing plastic bags. We lost the reorder.

We fixed it with differential shrinkage.

Here is the trick: We knit the face with normal polyester. We knit the back with high-shrinkage polyester. During finishing, the back shrinks more than the face. That creates microscopic air gaps. You get opacity from the dense face, breathability from the open back structure. No need for mesh holes.

We call it our "Air Gap" construction. We've shipped over 120,000 meters since 2022. It adds $0.18 per yard. Worth every cent.

Also, don't trust whiteness retention claims without AATCC 110 testing. We learned this with a Norwegian ski team order in 2021. Their jerseys looked great in our light box. After three days under UV in the Alps? Yellowed. Turns out the optical brightener wasn't stable. We now specify UV-stable brighteners and test accordingly. The whiteness retention standards for performance apparel saved that account.

Which Fabric Construction Works Best for Different Sports?

I used to think one jersey construction could rule them all.

- We developed a "universal" 200 gsm polyester jersey. Sold it to a distributor in Argentina. They sold it to soccer teams, basketball teams, even a rugby team.

Then the complaints started. Soccer players said it was too heavy. Rugby players ripped it in the first scrum. The basketball team loved it. But one sport wasn't enough to sustain the SKU.

Now we categorize by movement pattern, not just sport.

Here is the matrix we built after 15 years of trial and error:

| Sport | Primary Movement | Recommended Construction | GSM Range | Stretch Required |

|---|---|---|---|---|

| Basketball | Multi-directional jumps/cuts | Interlock or pique with spandex | 180-210 | 30-40% widthwise |

| Soccer/Football | Linear sprinting | Single jersey, mechanical stretch | 150-170 | 15-20% lengthwise |

| Volleyball | Vertical jumping, diving | Double knit with anti-snag | 200-230 | 25% bi-stretch |

| Baseball/Softball | Throwing, sliding | Woven polyester microfiber | 180-200 | Minimal, abrasion focus |

| Combat Sports | Grabbing, pulling | Nylon/spandex hybrid | 220-260 | 50%+ four-way |

| Running | Forward motion | Ultra-light mesh variations | 110-140 | 10-15% lengthwise |

Why do basketball teams need different stretch properties than soccer teams?

Basketball is about lateral explosion.

A power forward plants his foot and cuts 90 degrees. The fabric must stretch widthwise—across the grain. If it doesn't, the jersey rides up or binds.

Soccer is about forward thrust. The fabric needs to stretch lengthwise as the hamstring extends. Widthwise stretch? Not as critical.

We ignored this for years. In 2018, we sold a single-knit jersey with 25% lengthwise stretch to a Philippine basketball league. Good price. Good hand feel. But when the point guard crossed over, the neckline shifted 4 inches off his shoulder. Looked sloppy on TV.

We fixed it by adding 6% spandex in the course direction only. Not in the wales. That gave us 35% width stretch, only 12% length stretch. Perfect for basketball. The engineering of anisotropic stretch in circular knits became a core competency for us.

Here is a pro tip: If you are sourcing for basketball, fold the fabric widthwise. If it doesn't stretch at least 30%, reject it. No negotiation.

When should we choose double knit over single knit for durability?

Double knit sounds better. Two layers, right? Stronger?

Not always.

In 2022, a high school football program in Texas ordered our 240 gsm double knit for practice jerseys. They returned 30% after three months. The problem wasn't abrasion. It was snagging. The double knit construction created longer floats on the back. When players grabbed each other, those floats pulled and distorted the face.

We swapped them to a jersey stitch with a tuck pattern. Same weight, same opacity. But the tucks locked the floats in place. Snagging dropped 80%.

So here is my rule:

- Double knit = good for compression/base layers, volleyball, basketball (smooth surfaces, less grabbing)

- Single knit (with modifications) = better for football, rugby, any sport with high-frequency grabbing

Also, double knit traps more heat. We measured 0.8°C higher microclimate temperature in double knit vs single at 200 gsm. For summer sports? That matters. Players notice.

The thermal regulation comparison between knit structures validated what we saw in wearer trials. We now always ask: "What season? What climate?" before recommending construction.

How Do We Manage Color Consistency Across Multiple Jersey Orders?

Color is the reason we get returns.

Not quality. Not price. Color.

I remember 2017. A Dutch amateur cycling team. We made their blue jerseys. First batch: approved. Second batch, three months later: same recipe, same mill. But the client said: "These are not the same blue."

We pulled both fabrics. Measured with our spectrophotometer. Delta E: 1.1. Industry standard is 1.0. Technically, it passed. Visually, it failed. The customer saw what the machine missed.

We changed everything after that.

Now we don't rely only on Delta E. We do visual assessment under three light sources: D65 (daylight), TL84 (store lighting), and A (incandescent). If any inspector says "it looks different," we stop and rework.

Here is our current SOP for team color consistency:

| Control Point | Our Method | Why It Matters |

|---|---|---|

| Yarn lot traceability | Dye only from same spinning lot within 30 days | Nylon and polyester absorb dye differently batch to batch |

| Liquor ratio control | Record every dye batch; reject if variance >3% | Too much water = lighter shade |

| Post-set temperature | ±1.5°C tolerance on heat-setting frame | Temperature shifts change dye uptake |

| Physical standards | Retain 1 meter of every approved lab dip | Digital readings lie; eyes confirm |

| Shipment sampling | Cut 5 places across 10% of rolls | Edge-to-center shading kills jerseys |

How do we match colors across different fabric constructions?

This is the nightmare scenario.

A team wants the jersey in single knit, the shorts in double knit, and the warm-up jacket in woven microfiber. Same color. Impossible? Almost.

Polyester dyes differently on every construction.

The single knit reflects light differently than the double knit. The woven microfiber has less surface area, so it looks darker even with the exact same dye concentration.

We learned this in 2020 with a South African rugby team. We shipped three different constructions. All measured within Delta E 0.8 of the standard. But when the team laid the jersey next to the shorts? Obvious mismatch. The client was furious.

Our solution: Substrate-specific standards.

We don't give one lab dip anymore. We give three. One for each construction. The client approves them side by side. We dye them separately, with adjusted recipes. The single knit gets 7% less dye. The woven gets 12% more. Then they match.

This costs more. More development time, more samples. But we haven't lost a color-matching client since 2021. The methodology for cross-construction color matching in polyester is something we've refined over 50+ trials. I can share our adjustment factors.

What is the acceptable color variance for team uniforms?

Here is the truth: Delta E 1.0 is too loose for team sports.

Fashion? Fine. If a blouse is slightly off, nobody compares it to last season's blouse side-by-side.

Team uniforms? They stand in a line. Shoulder to shoulder. Number 7 next to number 10. If number 7's jersey is 0.5% more red, the whole line looks wrong.

In 2018, we adopted Delta E 0.6 as our internal standard for team orders. Not the industry standard. Our standard.

We can hit it. But it requires:

- Single-source yarn lots

- No rush dye cycles (minimum 45 minutes dwell)

- Cooling before framing

- 100% spectrophotometer inspection, not sampling

We charge 4% more for this level of control. Most brands pay it. Because returns cost more than 4%.

I tell clients: "If you want Delta E 1.0, I can save you money. If you want 0.6, I can save your reputation." They usually pick reputation.

The sports apparel color consistency guidelines from major leagues actually specify visual acceptability, not just numbers. We follow that principle.

How Do Factory Holidays and Peak Seasons Affect Team Jersey Lead Times?

I mentioned peak seasons in your background. March-May and August-October. Those are our hell months.

Why? Because every sport starts at the same time.

European soccer clubs order in March. US high school football orders in April. Australian rugby orders in August. Everyone wants delivery "before the season." Everyone calls it "urgent."

We cannot compress time during peak season.

In 2022, we tried. A Mexican baseball league ordered 18,000 yards of pique jersey. Order came April 3. They needed it May 15. Normally: 6 weeks. We said yes.

We ran out of greige yarn. Our supplier had a 3-week backlog because three other mills were also weaving for the MLB season. We air-freighted yarn from Thailand. Cost us $8,200. Then the dyehouse hit capacity. We paid overtime: +30% labor. We shipped May 18. Three days late. Client was unhappy. We made almost zero profit.

Now I enforce cutoff dates.

| Season | Order Deadline | Delivery Guarantee |

|---|---|---|

| Spring/Summer (Europe) | February 1 | April 1 |

| Fall/Winter (Europe) | July 1 | September 1 |

| US School Sports | March 1 | June 1 |

| Southern Hemisphere | May 1 | August 1 |

If you miss the deadline, we don't say no. We say: "We can try. But you must approve 14-day potential delay and 12% rush surcharge." Most clients wait until next season.

How do we secure yarn inventory before Chinese New Year?

CNY is the concrete wall.

Three weeks of nothing moving. Not yarn, not fabric, not trucks. If your yarn isn't in our warehouse by the second week of January, you aren't producing until March.

Here is what we do for smart teams:

In November, I personally review every active team jersey program. I calculate: Yarn needed for January production. I place those yarn orders in October. Not December. October.

We pay 30% deposit to lock the yarn. Even if the client hasn't confirmed their order yet. We take the risk. Why? Because in 2019, we didn't. A German team confirmed January 5. We ordered yarn January 6. Supplier said: "Sorry, CNY shutdown starts January 20. We can't spin 8 tons in 14 days." We lost the order.

Now we forecast. We use inventory hedging strategies for textile raw materials. It's not perfect. Sometimes we hold yarn for 4 months. Carrying cost is about 1.2% per month. But having the yarn on the cone beats explaining to a client why their jerseys won't arrive until May.

At Shanghai Fumao, we treat inventory as a service, not a cost center. We carry 150 tons of greige jersey in stock year-round. White only. We can piece dye any color in 10 days. Even during peak. Even before CNY.

What is the realistic timeline for sublimation-ready jersey fabric?

Sublimation printing adds a layer.

Not just printing. The fabric must be heat-set perfectly flat. If there is even 2% residual shrinkage, the print distorts during transfer.

In 2023, a British cricket team ordered sublimation-ready white pique. We heat-set at 190°C, 20 meters per minute. Standard. They printed. The registration was off by 3mm on 30% of the panels. Unacceptable.

We investigated. Our heat-setting was fine. The problem: The greige yarn had higher than normal amorphous regions. It shrank more during sublimation. We didn't test for that.

Now our sublimation-ready protocol is:

- Receive yarn

- Test differential scanning calorimetry (DSC) for crystallinity

- If crystallinity < 45%, adjust heat-set temp +5°C

- Pre-shrink sample in sublimation oven before bulk production

- Ship only after shrinkage test passes at client's nominated transfer temp

This adds 5 days. But it eliminates print misregistration. Since implementing, zero sublimation returns. The DSC method for polyester heat-setting optimization is in our ISO manual now.

Total timeline for sublimation-ready jersey, if you ask today:

- Yarn sourcing: 10-14 days (in stock)

- Knitting: 7-10 days

- Heat-setting: 3 days

- QC & packaging: 3 days

- Total: 23-30 days

Add 14 days if you miss the yarn cutoff. Add 21 days if it's peak season. Add 30 days if you need certification like OEKO-TEX® or GRS.

Plan accordingly.

What Certifications Are Required for Exporting Team Jerseys to the US and EU?

Ron asks me about compliance every time.

He has reason to. In 2020, one of his suppliers shipped 40,000 jerseys without proper PFAS testing. US Customs flagged it. The fabric had a residual water repellent from a previous run—cross-contamination. Ron's client had to destroy the entire lot. Six figures, gone.

Certifications are not optional for team jerseys.

Schools, leagues, corporate sponsors—they all require documentation. Not just "we tested it." Actual certificates from accredited bodies.

Here is the minimum we recommend:

| Market | Required Certification | What It Verifies |

|---|---|---|

| EU | OEKO-TEX® Standard 100 Class I | Harmful substances for baby/near-skin |

| US | CPSIA compliance (lead/phthalates) | Children's product safety |

| Global | GRS (Global Recycled Standard) | Recycled content claim verification |

| EU Corporate | ISO 14001 / Sustainable sourcing policy | Environmental management |

| US Schools | Prop 65 compliance (if sold in CA) | No detectable carcinogens/reprotoxins |

Does recycled polyester perform the same as virgin for jerseys?

Short answer: Almost. But not exactly.

We started offering rPET (recycled polyester) in 2019. A Swedish brand wanted 100% recycled jerseys. We sourced bottle-grade flakes, melt-spun them, knitted 185 gsm single jersey.

The fabric was 12% weaker in tear strength. Elmendorf dropped from 18 lbs to 16 lbs. Still passed spec. But the bigger issue was dye uptake.

Recycled polyester dyes darker. The polymer chains are shorter. More dye sites. Our first batch came out 30% darker than the standard. We had to reformulate the recipe. Added 5 days.

Now we blend.

For team jerseys, we recommend 70% virgin / 30% recycled. You get the sustainability story. You get consistent dyeing. You get tear strength retention.

100% recycled works. But you need to approve a separate color standard. Don't expect it to match your virgin inventory.

We've shipped over 800,000 meters of rPET jersey since 2021. The performance data on recycled polyester in sportswear confirms what we see: slightly lower tenacity, slightly higher dye affinity. Manageable if you know the variables.

At Shanghai Fumao, we carry GRS-certified rPET yarn in stock. 75 denier, 36 filaments. White and black only. Piece dye to your color. Saves 3 weeks.

How do we prove UFLPA compliance for cotton-blend team jerseys?

Cotton in team jerseys is coming back. 2023-2024, we saw a 40% increase in requests for cotton/poly blends. Soft hand feel, less static, "natural" marketing angle.

But cotton brings UFLPA risk.

If your cotton originates in Xinjiang, your jerseys will be detained. Period. We don't take that chance.

Our protocol:

- Only use cotton from Better Cotton Initiative (BCI) licensed farms outside Xinjiang

- Maintain chain of custody documents from gin to spinning mill

- Provide UFLPA compliance statement with every shipment

- If client requires, submit e214 shipment data with cotton origin declared

In 2023, we shipped 55,000 meters of cotton/poly blend jerseys to a California university. We provided the full traceability package. Customs cleared in 2 hours.

We also offer TENCEL™ as a cotton alternative. Cellulosic fiber, FSC-certified wood pulp, not subject to UFLPA. Shrinkage is higher, but we pre-shrink at finishing. The UFLPA compliance framework for textile imports changes constantly. We subscribe to CBP alerts. We adjust.

If you source cotton jerseys, demand the farm certificate of origin. Not just the mill statement. If the supplier hesitates, walk away. It's not worth the detention.

Conclusion

Sourcing fabric for athletic team jerseys is not about picking the cheapest polyester.

It's about knowing that basketball needs width stretch and soccer needs length stretch. It's about testing wash durability with the actual detergent the team mom will use. It's about having yarn on the cone before the client even signs the PO, because Chinese New Year doesn't care about your season start date.

I've been in this since 2006. I've seen moisture-wicking finishes that washed off after three games. I've seen white jerseys turn yellow in the alpine sun. I've seen Delta E 1.1 cause a $90,000 return.

But I've also seen the wins.

- A Mexican soccer team. 14,000 jerseys. We delivered on March 28. Their season started April 2. They won the championship. The owner sent me a photo of the team holding the trophy, wearing our fabric. That's why I do this.

That is also why we don't cut corners.

At Shanghai Fumao, we are not the cheapest. You can find polyester jersey for $1.80/m in Keqiao. Probably from a trader. Probably without test reports. Probably without traceability.

We charge more. Because we test the yarn crystallinity. We hold the inventory. We match colors at Delta E 0.6. We keep UFLPA compliance files for every cotton blend. We pre-shrink TENCEL so your medium stays a medium.

And we deliver before the season starts.

So if you are sourcing for a high school team, a professional club, or a national federation—talk to us.

Email Elaine, our Business Director, directly: elaine@fumaoclothing.com. Tell her what sport. Tell her your deadline. Tell her your color targets.

She will connect you with our technical knit team. We will pull the yarn cones. We will run the moisture management tests. We will build the timeline that accounts for the peak season backlog and the CNY shutdown.

We won't promise you the lowest price. We will promise you jerseys that perform, colors that match, and delivery you can trust.