You need a fabric that does something: it must repel water permanently, resist flames to a specific standard, or kill bacteria on contact. A standard cotton or polyester won't cut it. You're searching for technical fabrics with functional coatings, and you've hit a wall—suppliers either don't have the tech, can't verify performance, or demand impossible minimums. This isn't a simple fabric buy; it's sourcing a engineered material system.

The right supplier isn't just a mill; it's a partner with vertical control over the base fabric construction, access to advanced chemical coating formulations, and a certified in-house testing lab to validate every claim. Finding them requires moving beyond general B2B platforms and into the specialized ecosystems where material innovation happens.

Let's map out a proven strategy to identify, evaluate, and partner with a capable supplier who can turn your performance specifications into a reliable, compliant, and cost-effective reality.

Where to Look for Specialized Coating Suppliers?

The first mistake is only searching "waterproof fabric supplier" on Alibaba. You'll drown in resellers who can't explain the coating chemistry. You need to target the specific industrial clusters and professional channels where this expertise is concentrated.

Start with the geographic hubs. In China, for PU/PVC coatings, the Shengze and Zhangjiagang regions in Jiangsu are powerhouses. For flame retardant (FR) finishes, the Guangdong corridor has deep expertise. For high-tech nano or graphene coatings, look to suppliers linked to university R&D hubs in Shanghai or Shenzhen. Use this geographic focus to refine your online searches (e.g., "Zhangjiagang PU coating factory") and target relevant trade shows like Techtextil or Performance Days, where suppliers showcase their core technologies, not just fabric swatches.

Secondly, move upstream in your search terms. Instead of searching for the final fabric, search for the coating chemical suppliers (e.g., "fluorocarbon-free DWR manufacturer"). Then, investigate which fabric mills they partner with. This reverse-engineering often leads you to the most technically advanced partners.

Are Trade Shows or Online Platforms More Effective?

For technical coatings, specialized trade shows are irreplaceable. At events like Techtextil, you can feel the hand of the fabric, see the coating's uniformity, and have in-depth conversations with R&D managers. You can ask, "What's the hydrolysis resistance of this PU coating?" and get an immediate, expert answer. In 2023, at the Shanghai Texcare, we connected with a German chemical firm that introduced us to their partner mill—a relationship that later allowed us to develop a market-leading antibacterial and antiviral coating for a client in the healthcare uniform sector.

Online platforms (Alibaba, Made-in-China) serve best for initial long-listing and verifying basic credentials (business licenses, export volume). Use them to find suppliers, then immediately dig deeper. The most capable ones will have detailed technical data sheets (TDS) downloadable from their website, not just glossy marketing photos. A key red flag is a supplier who cannot provide a TDS for their coating formulation.

How to Verify a Supplier's Real Technical Capability?

You must go beyond sales reps. Ask to speak directly with their technical or R&D department. Pose specific scenario-based questions: "If I need a polyester fabric with a WP of 10,000mm and a MVTR of 8,000g/m²/24hrs, plus a durable anti-bacterial finish, how would you engineer the base cloth and layer the coatings? What testing standards will you use?"

Demand a factory audit report (they should have recent ones from SGS, Bureau Veritas, or major brands) and proof of in-house testing equipment. At Shanghai Fumao, we invite key clients to visit our CNAS-accredited lab. We show them the salt spray tester for corrosion-resistant coatings, the vertical flame chamber for FR tests, and the Martin Dale abrasion tester. Seeing is believing. A supplier's willingness to be transparent about their process is the first true test of their capability.

What Questions to Ask About Coating Processes and Durability?

The coating is only as good as its bond to the fabric and its longevity. This is where projects fail—when the "waterproof" fabric leaks after 5 washes. Your questioning must be ruthlessly specific.

First, ask about pre-treatment. Is the base fabric scoured and heat-set to ensure a clean, stable surface for coating adhesion? Poor pre-treatment leads to delamination. Next, drill into the coating method itself: Is it knife coating, roller coating, foam finishing, or laminating? Each has different implications for hand feel, breathability, and cost. For instance, a microporous PU coating applied via knife over a mesh creates a different performance profile than a PU laminate.

Finally, and most crucially, interrogate durability testing protocols. Ask: "What is the tested wash durability for this DWR finish? Can you show me AATCC 135 test results after 5, 10, and 20 home/commercial washes?" For abrasion resistance, ask for Martindale or Wyzenbeek test cycles until coating failure.

How is Coating Adhesion and Wash Durability Tested?

Reputable suppliers will follow international standards. Coating adhesion is typically tested via the peel strength test (e.g., ASTM D751). A machine measures the force required to peel the coating from the fabric. We perform this on every batch.

For wash durability, the process is rigorous. Fabric samples are subjected to repeated wash cycles (using controlled parameters for detergent, temperature, and agitation) per AATCC 135. After the prescribed cycles, the key performance attribute (e.g., water resistance, flame resistance) is retested. For a recent project with a US workwear brand, we provided full data showing our fluoro-free DWR maintained a 80/80 rating in spray test (AATCC 22) after 30 industrial washes, meeting their stringent contract requirements. Always ask for this longitudinal data, not just a "pass" for initial state.

What's the Difference Between a Coating and a Laminate?

This is a fundamental technical distinction that impacts performance, feel, and cost.

- Coating: A chemical formulation (PU, PVC, acrylic) is applied directly to one surface of the base fabric. It can be thin and breathable (like many moisture-management coatings) or thick and impermeable (like truck tarpaulin coating). It tends to alter the hand feel of the fabric side it's applied to.

- Laminate: A pre-made, often microporous membrane (like ePTFE/Gore-Tex or a TPU film) is bonded to the base fabric using heat and adhesive. It is typically more consistently waterproof/breathable and has a distinct, often crinkly, hand. It is usually more expensive.

A simple analogy: Coating is like painting a wall. Lamination is like gluing a special wallpaper to it. For extreme weather protection (mountaineering), laminates are often preferred. For everyday water resistance with better drape (urban rain jackets), advanced coatings may suffice. A good supplier like Shanghai Fumao will advise you on the most cost-effective and performance-appropriate route.

How to Manage MOQs and Navigate Compliance?

Technical coating runs have high setup costs for the chemical kitchen and machine calibration. Therefore, Minimum Order Quantities (MOQs) are a significant hurdle. Understanding how to navigate them is key.

Typical MOQs for a custom-coated fabric can start at 1,000 to 3,000 meters, depending on complexity. However, strategies exist. You can work with a supplier who stocks standard base greige fabrics (e.g., a 70D nylon taffeta) and only customizes the coating. This slashes the MOQ. Another strategy we use is batch consolidation. If multiple clients need a similar black FR coating, we can combine their orders into one master batch and then split it.

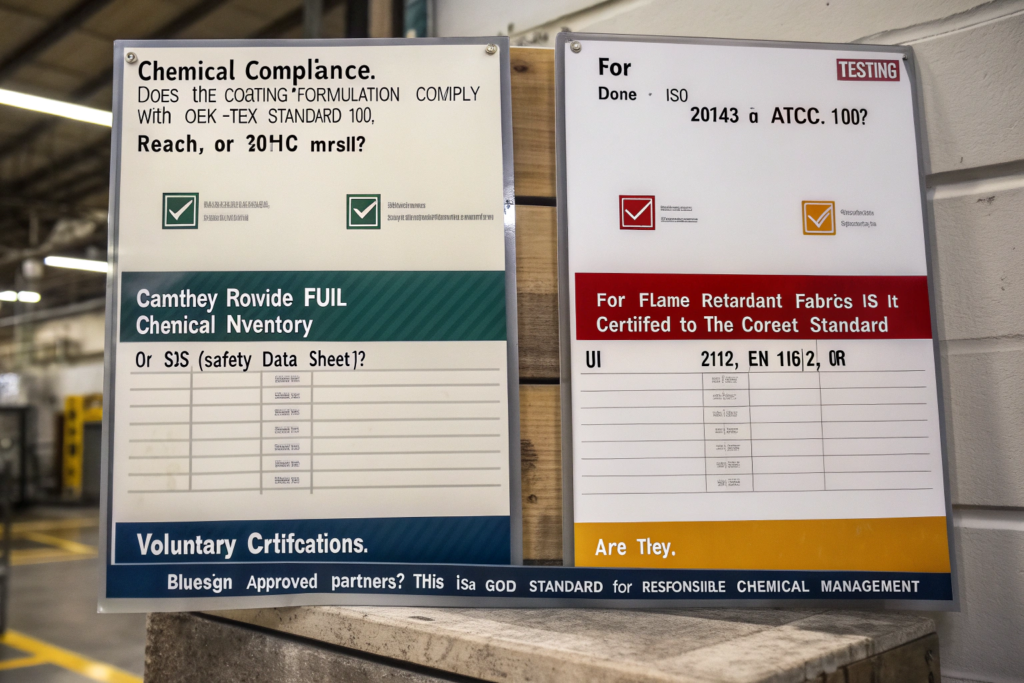

On compliance, this is non-negotiable. You must ask:

- Chemical Compliance: Does the coating formulation comply with OEKO-TEX Standard 100, REACH, or ZDHC MRSL? Can they provide a full chemical inventory or SDS (Safety Data Sheet)?

- Performance Certification: For Flame Retardant fabrics, is it certified to the correct standard (e.g., NFPA 2112, EN 11612, or UL certified)? For medical antimicrobials, is testing done to ISO 20743 or AATCC 100?

- Voluntary Certifications: Are they bluesign® approved partners? This is a gold standard for responsible chemical management.

What Are Realistic MOQs for Custom Coatings?

It depends entirely on the "custom" scope. Here's a breakdown from our experience at Fumao:

| Customization Level | Typical MOQ Range | Example Scenario |

|---|---|---|

| Coating Only (on our stock base fabric) | 500 - 1,500 meters | Applying a custom color PU coating to a standard polyester oxford. |

| Base Fabric + Coating (full custom) | 2,000 - 5,000 meters | Developing a new ripstop nylon weave with a proprietary graphene-based thermal coating. |

| Stock Coated Fabrics | As low as 100 meters | Purchasing from our existing inventory of pre-coated fabrics (e.g., standard silver antimicrobial lining). |

The key is transparent conversation early on. Share your performance targets and volume forecasts. A good partner will work to find a solution, perhaps suggesting a phased approach: using a stock coated fabric for your first small collection, then investing in a custom development once volumes justify it.

How to Ensure Compliance with EU/US Regulations?

Due diligence is your responsibility. Require your supplier to provide test reports from accredited third-party labs (SGS, ITS, TÜV). Do not accept "in-house" reports for final compliance. For the EU, ensure coatings are free from PFAS (C8/C6) and other restricted substances per REACH. For the US, understand relevant CPSIA and California Prop 65 requirements.

We manage this by maintaining a digital compliance dossier for each coated fabric. When you scan the QR code on your fabric roll from us, you can access not only the physical test reports but also the chemical compliance certificates and chain of custody for certified materials. This traceability is essential for passing audits from major brands or retailers. In 2024, this system helped a European client swiftly comply with new EU eco-design regulations for durable water repellency, saving them months of documentation work.

Conclusion

Sourcing technical coated fabrics is a technically complex, compliance-sensitive endeavor. The goal is not to find the cheapest supplier, but the most competent and transparent partner. The right partner acts as an extension of your R&D team, guiding you from concept to compliant bulk production.

They will have the vertical integration to control quality, the laboratory to validate performance, and the expertise to navigate the intricate landscape of chemical regulations and durability standards. This partnership transforms a high-risk sourcing challenge into a reliable, value-adding component of your product's success.

Struggling to find a reliable technical fabric partner? Shanghai Fumao operates at the intersection of advanced textile manufacturing and functional chemistry. With our own coating factory, CNAS-accredited lab, and deep expertise in global compliance, we are built to be your solution partner for demanding technical fabric needs. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your specific coating performance requirements. Let's engineer the solution together.