The sustainable fashion movement has transformed from a niche interest to a core industry requirement. As an established fabric supplier based in Keqiao, China's textile hub, I've witnessed this shift firsthand. American brands increasingly seek recycled nylon fabrics that combine environmental responsibility with commercial viability. This comprehensive guide addresses your fundamental question while providing practical sourcing strategies.

Successfully sourcing recycled nylon swimwear fabric requires verifying certifications like GRS, testing functional properties like chlorine resistance, evaluating supplier development capabilities, and establishing reliable logistics channels. This multifaceted approach ensures you acquire materials that meet both sustainability standards and performance demands.

Understanding Essential Certifications and Standards

Certifications provide the foundational verification for any sustainability claim. Without proper documentation, environmental benefits remain unsubstantiated. The certification landscape for recycled materials combines content verification with safety assurance.

The Global Recycled Standard (GRS) offers the most recognized verification for recycled content. This certification tracks materials from post-consumer or post-industrial waste through the entire production process. When suppliers provide GRS-certified fabric, you gain transparent evidence to support marketing claims about recycled content.

Complementing content verification, OEKO-TEX Standard 100 ensures product safety. This certification tests for harmful substances that could affect wearer health. For swimwear contacting skin extensively, this safety assurance becomes particularly valuable. The combination of GRS and OEKO-TEX creates a comprehensive sustainability and safety profile that meets market expectations.

What certification combinations provide maximum credibility?

While GRS and OEKO-TEX form a strong foundation, additional certifications enhance credibility. REPREVE certification specifically verifies recycled polyester and nylon content through a traceable system. Similarly, bluesign® certification addresses environmental impact across the manufacturing process. These complementary certifications demonstrate deeper commitment to sustainable production.

How can buyers verify certification authenticity?

Always request original certification documents from suppliers, then verify through the certifying bodies' databases. Reputable suppliers willingly provide this information. At Fumao Textiles, we maintain transparent certification records and implement QR code tracking that allows direct access to verification data.

Evaluating Performance and Quality Parameters

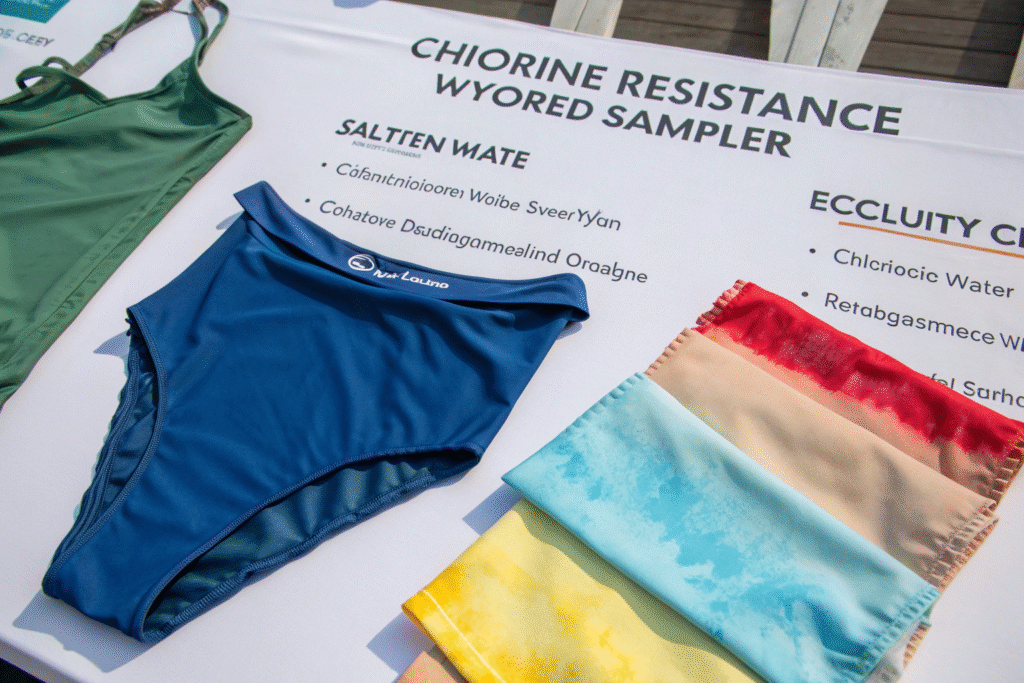

Certification establishes what the fabric represents, while performance testing determines how it functions. Swimwear demands exceptional durability under challenging conditions including chlorine exposure, saltwater, UV radiation, and repeated stretching.

Chlorine resistance represents the most critical performance factor for swimwear fabric. Prolonged chlorine exposure degrades elastic fibers and causes color fading. Quality recycled nylon should demonstrate excellent colorfastness when tested against chlorinated water. Similarly, resistance to saltwater and perspiration ensures maintained appearance through extended use.

Beyond chemical resistance, physical durability indicators include bursting strength and abrasion resistance. Bursting strength measures pressure tolerance, simulating stress during active wear. Abrasion resistance indicates how well fabric withstands contact with rough surfaces like pool decks. These combined tests predict real-world durability.

What performance standards differentiate quality levels?

Premium swimwear fabric typically achieves UPF 50+ ultraviolet protection, blocking over 98% of harmful UV rays. Combined with reliable four-direction stretch recovery and minimal water absorption, these characteristics define high-performance swimwear materials. Consistent performance across these metrics separates adequate fabrics from exceptional ones.

Does recycled nylon compromise performance compared to virgin material?

Modern recycling technologies produce regenerated nylon that matches virgin material performance. Through advanced polymerization processes, recycled nylon maintains strength, elasticity, and durability while offering environmental benefits. The performance equivalence makes sustainable sourcing decisions commercially viable.

Navigating Supplier Selection and Development Processes

Supplier capabilities directly impact both product quality and development efficiency. The ideal partner combines technical expertise with flexible development processes that accommodate varying production volumes.

Sampling speed indicates supplier responsiveness and technical capability. Efficient suppliers typically deliver initial samples within 3-5 days, allowing rapid design iteration. This agility becomes particularly valuable when developing seasonal collections with compressed timelines. Our 48-hour sample development commitment exemplifies this responsive approach.

Technical collaboration represents another critical selection factor. Knowledgeable suppliers guide material selection, recommending appropriate fabric weights, construction methods, and finishing techniques for specific designs. This collaborative approach prevents costly specification errors and optimizes material performance.

What questions help evaluate supplier expertise?

Inquire about previous swimwear projects, testing protocols, and customization capabilities. Request references from similar clients and examine physical samples from current production. These investigations reveal practical experience beyond marketing claims.

How do MOQ policies affect development flexibility?

Minimum order quantity policies significantly impact new product development. While traditional manufacturers often require large minimums, progressive suppliers offer small-batch production options. This flexibility enables market testing and limited editions without excessive inventory commitment.

Managing Logistics and Cost Considerations

Efficient logistics management ensures timely delivery while controlling costs. Understanding shipping options, tariff implications, and supply chain transparency measures prevents unexpected complications.

Shipping method selection balances speed against cost. Air freight delivers speed for time-sensitive projects, while sea shipping offers economical transportation for larger quantities. Strategic suppliers provide multiple options and guidance selecting the optimal approach for specific situations.

Tariff management requires understanding Harmonized System codes and applicable trade regulations. While certain fabrics from China face additional duties, experienced suppliers provide accurate classification guidance and documentation. This expertise prevents unexpected cost increases and customs delays.

What logistics indicators predict reliable delivery?

Consistent transit times, professional documentation, and proactive communication characterize reliable logistics partners. Advanced suppliers implement tracking systems that provide real-time shipment visibility, enabling accurate planning and inventory management.

How can importers optimize total landed cost?

Beyond fabric price, consider duties, shipping expenses, and payment terms when calculating total cost. Consolidated shipping, proper documentation, and strategic sourcing decisions collectively optimize the final delivered price while maintaining quality standards.

Conclusion

Sourcing recycled nylon swimwear fabric requires balancing sustainability credentials, performance requirements, supplier capabilities, and logistical practicalities. The optimal approach combines thorough certification verification with rigorous performance testing, followed by careful supplier evaluation and logistics planning.

This comprehensive methodology ensures your swimwear line meets both environmental goals and commercial requirements. By addressing each element systematically, brands can confidently source materials that satisfy consumer expectations for sustainability and quality.

For personalized assistance developing your swimwear collection with premium recycled nylon fabrics, contact our Business Director Elaine at elaine@fumaoclothing.com. Our team brings decades of textile expertise and sustainable manufacturing experience to help transform your concepts into market-ready products.