As a fabric manufacturer with over two decades in the textile hub of Keqiao, I often get asked by clients like Ron from the U.S. to clarify the core differences between dye types. Choosing the right dye can make or break your fabric's quality, cost, and market appeal. It directly impacts your bottom line, especially when dealing with international shipping and tariffs.

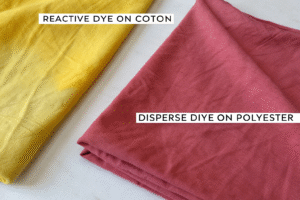

Understanding the distinction between reactive dye and disperse dye is fundamental for any clothing brand or procurement specialist. In simple terms, reactive dyes are primarily used for coloring cellulosic fibers like cotton, forming a covalent bond with the fabric. Disperse dyes, on the other hand, are designed for synthetic fibers like polyester, where the dye dissolves into the fiber itself. This fundamental difference dictates everything from the fabric's handfeel to its colorfastness properties.

This guide will break down the key differences, applications, and advantages of each dye type. You will learn how to select the right dye for your specific fabric needs, ensuring quality and efficiency in your production line. Let's dive into the essential knowledge that will help you make informed sourcing decisions.

What is reactive dye used for?

If you work with natural fabrics, you've likely encountered reactive dyes. They are the go-to choice for achieving brilliant and long-lasting colors on cellulose-based materials. But what exactly makes them so suitable, and how can they benefit your product line?

Reactive dyes are primarily used for dyeing natural cellulosic fibers such as cotton, linen, hemp, and rayon. They are famous for their excellent colorfastness and bright shades. The key lies in the chemical reaction: during the dyeing process, a covalent bond forms between the dye molecule and the hydroxyl group of the cellulose fiber. This bond is incredibly strong, making the color a permanent part of the fabric itself, rather than just sitting on the surface.

Why is colorfastness crucial for cotton fabrics?

Colorfastness is a non-negotiable quality for any apparel that requires frequent washing. For brands focused on natural fibers like cotton, reactive dyes offer superior resistance to fading. The covalent bond ensures that the color remains vibrant even after multiple washes, exposure to sunlight, and perspiration. This is why we insist on using high-quality reactive dyes for our organic cotton and linen product lines. It directly translates to higher customer satisfaction and fewer returns, which is a critical concern for price-conscious yet quality-focused buyers like Ron.

How does the reactive dyeing process work?

The process is a marvel of textile chemistry. It typically involves several stages: first, the fabric is prepared and cleaned. Then, the dye is applied in an alkaline bath (often with salt). The alkalinity activates the fiber, allowing the dye to penetrate. Finally, a fixation step, usually through steaming or heating, triggers the chemical reaction that forms the permanent bond. After this, the fabric is thoroughly washed to remove any unfixed dye. This meticulous process, overseen by our CNAS-accredited lab, ensures that every meter of fabric meets the highest international standards for color retention and safety, giving you peace of mind for your bulk orders.

What is disperse dye for polyester?

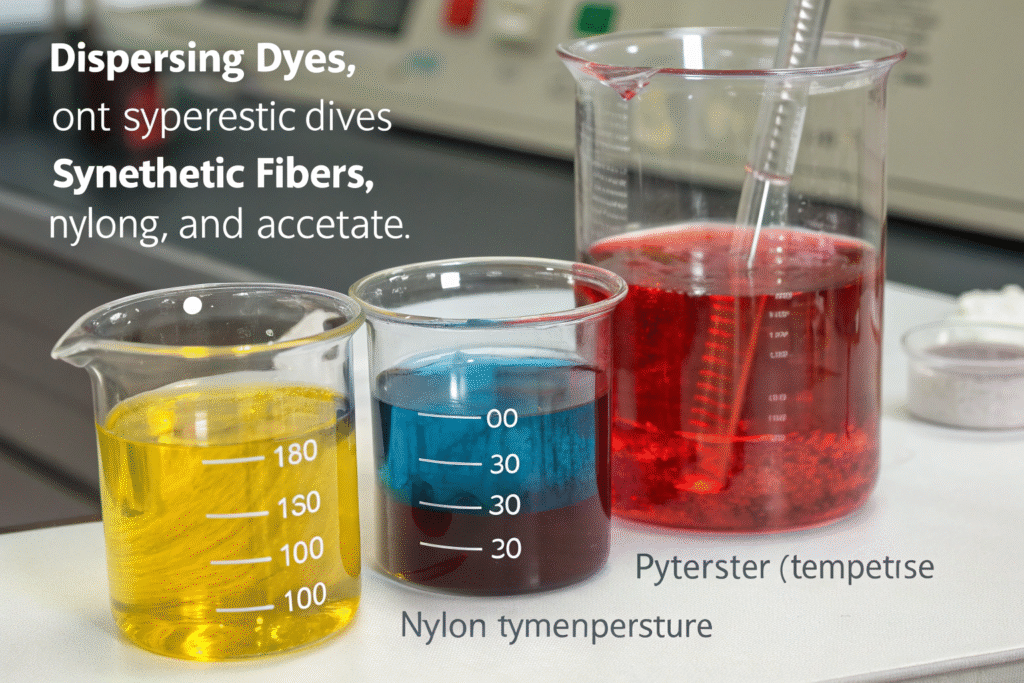

When your design calls for synthetic performance, disperse dyes step into the spotlight. They are the unsung heroes behind the vibrant colors of your athletic wear and outdoor gear. Understanding their unique properties is key to leveraging the benefits of polyester fabrics.

Disperse dyes are specially formulated for dyeing hydrophobic, synthetic fibers like polyester, nylon, and acetate. Unlike water-soluble dyes, disperse dyes are ground into a fine paste and dispersed in water. They are applied under high temperature and pressure, which causes the synthetic fibers to swell. This allows the dye molecules to diffuse inside the fiber and solidify upon cooling, creating a solid solution of color within the fabric.

What makes disperse dyes ideal for athletic wear?

The performance demands of athletic wear are unique. It requires fabrics that are durable, lightweight, and resistant to sweat and friction. Disperse dyes excel here because the color becomes part of the polyester fiber. This results in excellent wash-fastness and resistance to fading from chlorine and UV exposure. For our moisture-wicking and UV-resistant polyester fabrics, this dyeing method ensures the functional properties and the vibrant colors remain intact throughout the garment's lifespan, meeting the high standards of brands like Lululemon.

How is the disperse dyeing process different?

The primary method for applying disperse dyes to polyester is High-Temperature High-Pressure (HTHP) dyeing. This process involves temperatures above 130°C (266°F), which is necessary to open up the dense molecular structure of polyester. Alternatively, for continuous dyeing, a thermofixation process is used after padding the dye onto the fabric. A crucial step for certain shades is reduction clearing, a post-dyeing wash that removes any superficial dye particles to maximize crockfastness and wash-fastness. Our partnership with local dyeing factories ensures this technically demanding process is executed flawlessly, guaranteeing consistent results for your bulk shipments.

Reactive vs disperse dye: which is better?

The question isn't which dye is universally better, but which is better for your specific application. The choice hinges entirely on the fiber content of your fabric and the performance you need to deliver to your end-consumer. Making the wrong choice can lead to poor quality, unhappy customers, and lost revenue.

The core difference is their target fiber. Reactive dyes bond with hydrophilic (water-loving) natural fibers, while disperse dyes diffuse into hydrophobic (water-repelling) synthetic fibers. This fundamental distinction dictates their application methods, color range, and fastness properties. There is no one-size-fits-all answer; the "best" dye is the one that matches your fabric's composition.

How do I choose between reactive and disperse dyes?

Your choice should be guided by a simple flowchart based on your primary fiber:

| Primary Fiber in Your Fabric | Recommended Dye Type | Key Reason |

|---|---|---|

| Cotton, Linen, Rayon | Reactive Dye | Forms a chemical bond for brilliant, wash-fast colors. |

| Polyester, Nylon | Disperse Dye | Dissolves into the fiber for durable, vibrant shades. |

| Cotton/Polyester Blend | Both (Two-Step Process) | Requires a complex process to dye both fibers effectively. |

For blended fabrics, the process becomes more complex and costly. A 65/35 poly-cotton blend, for instance, typically requires a two-bath dyeing method: first using disperse dyes for the polyester, and then reactive dyes for the cotton. Our agile R&D team specializes in optimizing these processes to maintain your target price point without compromising on quality.

What are the cost and environmental impacts?

From a cost perspective, the reactive dyeing process often uses more water and chemicals (salt, alkali) for fixation and washing, which can increase water treatment costs. Disperse dyeing requires significant energy input for high temperatures. Environmentally, the runoff from reactive dyeing, if not treated, can have a higher Biological Oxygen Demand (BOD), while disperse dyes need careful management to avoid potential issues with heavy metals in some dye chemistries. At Fumao, our ¥550M green investment focuses on water recycling and energy-efficient machinery to mitigate these impacts across both dye types.

How to ensure fabric dyeing quality control?

Specifying the dye type is just the first step. Ensuring consistent, high-quality results batch after batch is where a reliable manufacturer truly adds value. For a buyer like Ron, who is oceans away, robust Quality Control is the foundation of trust.

Quality control in fabric dyeing is a multi-stage process that begins at the lab dip stage and continues through to final inspection. It verifies that the dyed fabric meets all required standards for color accuracy, durability, and safety. Our end-to-end QC, backed by a CNAS-accredited testing center, is designed to give you this assurance and guarantee a 98% client pass rate.

What tests verify dye quality and colorfastness?

A battery of standardized tests is performed to simulate the fabric's life cycle. Key tests include:

- Wash Fastness: Measures color resistance to washing.

- Rubbing/Crocking Fastness: Checks if color transfers when rubbed.

- Light Fastness: Determines resistance to fading from sunlight.

- Perspiration Fastness: Tests color stability against acidic and alkaline sweat.

We provide real-time access to these test reports, including data from SGS and ITS, via an advanced QR code tracking system. This transparency means you can verify the quality before the fabric even leaves our warehouse.

How does sourcing from China guarantee consistent quality?

Sourcing from a integrated manufacturer in Keqiao provides inherent QC advantages. We control the entire process, from yarn sourcing to dyeing and finishing, in a tightly-knit supply chain. This eliminates the communication gaps and finger-pointing that can occur with multiple disjointed suppliers. Our professional QC team is on-site at every stage – weaving, dyeing, printing – to catch issues early. Furthermore, our financial stability ensures we never cut corners on dye or chemical quality to manage cash flow, protecting the consistency of your bulk orders.

Conclusion

Choosing between reactive dyes and disperse dyes is a critical decision that hinges on your fabric's fiber content and performance requirements. Reactive dyes offer brilliant, lasting colors for natural fibers like cotton and linen, while disperse dyes provide durable vibrancy for synthetic fibers like polyester. We've explored their distinct applications, processes, and how quality control ensures the final product meets your expectations. Understanding these differences empowers you to make informed decisions that enhance your product quality and satisfy your customers.

Navigating the complexities of fabric dyeing and international logistics alone can be challenging. You need a partner who can ensure quality, manage tariffs, and deliver on time. Let Shanghai Fumao be that partner for you. We are ready to help you source or develop the perfect fabrics for your next collection. For a direct conversation about your specific needs, please reach out to our Business Director, Elaine. She will ensure you receive professional and comprehensive service. Contact Elaine today at elaine@fumaoclothing.com to start your next clothing order with confidence.