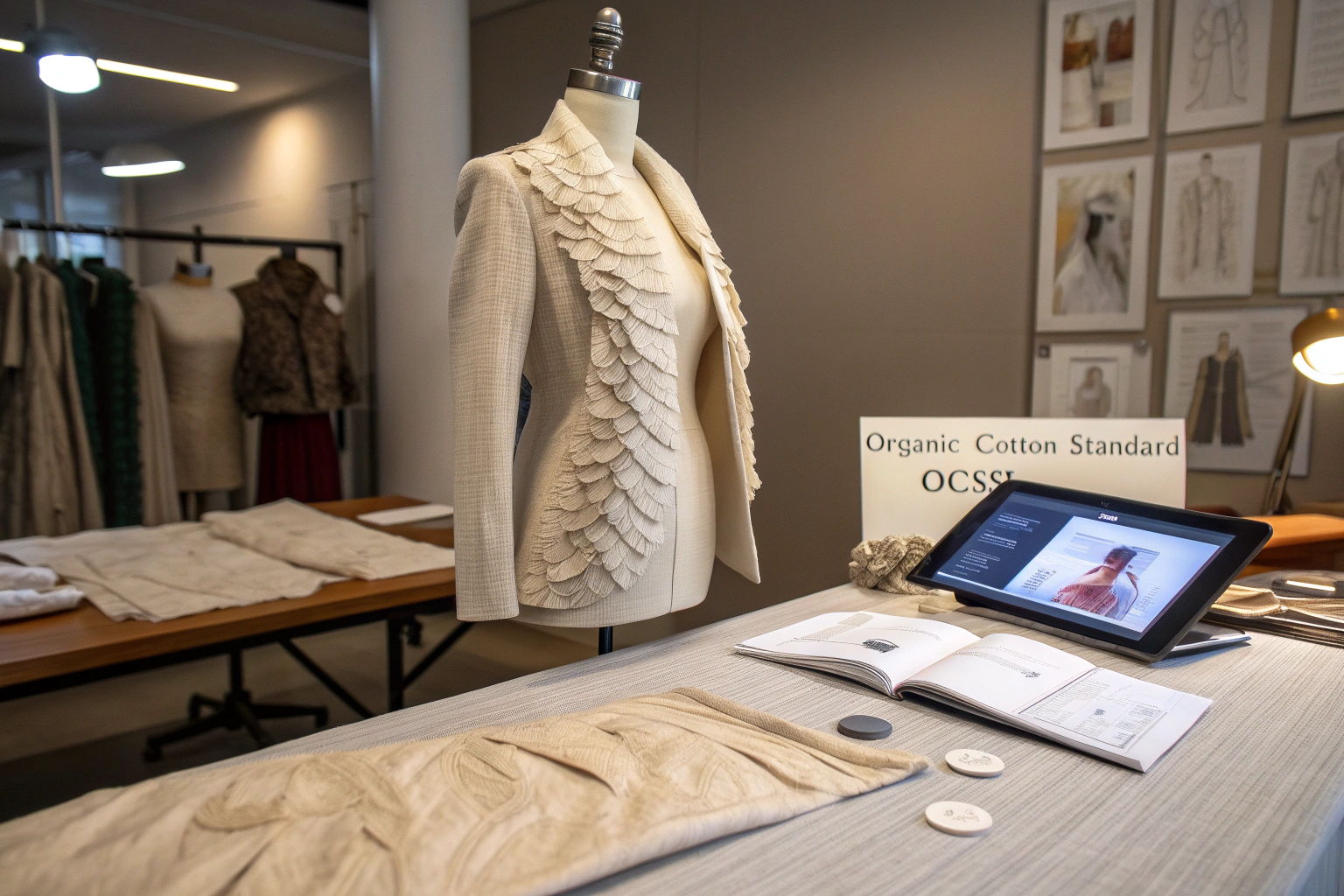

You're a designer. You dream of creating something breathtakingly unique—a garment that stops people in their tracks. But when you think "sustainable" or "organic," your mind conjures images of beige sack dresses and boxy basics. This, right here, is the industry's biggest lie. OCS-certified fabric is not a creative prison; it's a rare, untapped canvas. The real challenge isn't finding inspiration; it's dismantling the myth that ethical materials can't be avant-garde. I've seen designers create jaw-dropping, sculptural pieces with organic cotton twill and mind-blowing textures with organic linen-cupro blends. The rarity isn't limited by the fabric; it's limited by how you wield it.

Designing rare style clothing with OCS-certified fabric requires a paradigm shift: you must design from the fiber up, not the sketch down. It involves selecting and often co-developing specialty OCS fabrics (uncommon weaves, rare blends, innovative finishes), employing advanced construction techniques that honor the material's integrity, and integrating certification seamlessly into your design's storytelling as a mark of exclusive quality, not a compromise. This is where true luxury and sustainability converge.

Let's explore how to turn certified organic fabric from a constraint into your most powerful creative tool.

Phase 1: Sourcing the Rare Canvas – Beyond Basic Jersey

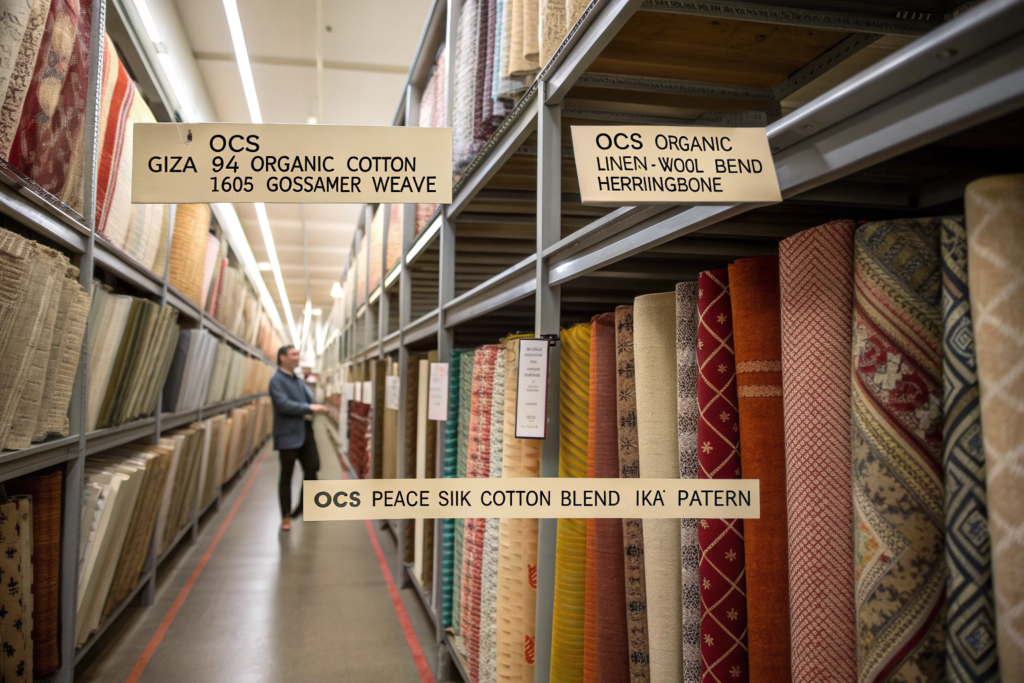

Your journey begins not with a sketchbook, but with a fabric library. The "rare" in your style will be fundamentally linked to the rarity of the material itself. You cannot design a groundbreaking piece with the same OCS jersey everyone else uses. You must seek out or create specialty OCS fabrics.

This means working with suppliers who see certification not as a limit, but as a challenge to innovate. You're looking for partners who have vertical control or deep connections to specialized mills that produce small-batch, certified fabrics.

What are the underutilized OCS fabrics for high-design?

Move past the commodity. Explore these categories:

- Heirloom Cottons: OCS-certified Giza 45, Supima, or Sea Island cotton varieties. These extra-long staple cottons produce fabrics with an unparalleled luster, strength, and silky hand-feel. They are rare, expensive, and perfect for luxury shirting, delicate blouses, or tailoring where drape and sheen are paramount.

- Structural Wovens: Organic cotton canvas (400+ gsm) for architectural jackets and bags. Organic cotton denim with novel slubs or colored wefts. Organic linen-cotton blends in complex weaves like jacquard or dobby for texture.

- Ethereal Sheers: OCS-certified organic cotton voile, lawn, or organdy. These can be layered, pleated, or embroidered to create volume and fragility simultaneously.

- Innovative Blends: Work with a mill to develop custom blends like OCS organic cotton with Tencel™ (Lyocell) for fluid drape, or with recycled cashmere for a unique loft and feel. The OCS component is certified; the other component needs its own certification (e.g., RCS for recycled).

The key is asking for what doesn't exist yet. In 2023, we worked with a Parisian designer to develop a custom OCS organic cotton-cupro blend for a slip dress collection. The cupro (made from cotton linter) added a liquid drape and subtle sheen that made the dresses utterly unique. The development took 3 months, but the result was a fabric—and a collection—that couldn't be copied.

How to develop custom OCS fabrics with a manufacturer?

This is a collaborative, R&D-intensive process.

- Start with a Fiber Vision: Approach your supplier with a concept: "I want a heavy, textured fabric with a dry hand, OCS-certified, for structured outerwear."

- Leverage Their Network: A good supplier (like Shanghai Fumao) will tap their spinning and weaving partners to propose yarn combinations and weave structures. They will manage the certification chain for the new development.

- Prototype and Test: Develop 50-100 meter sample runs. Test for drape, weight, color absorption, and durability. The OCS certification must be maintained for this prototype batch—this is non-negotiable and a sign of a serious partner.

- Lock in the Specs: Once approved, the exact fabric recipe (yarn source, count, weave, finish) is documented. This becomes your proprietary material, and the manufacturer secures the OCS-certified supply chain for it.

The MOQ for such developments will be higher (e.g., 1000-2000 meters), but it creates a true barrier to entry for your designs.

Phase 2: Designing with Integrity – Technique as a Signature

Now you have a rare fabric. The next step is to employ design and construction techniques that amplify its unique properties, not fight them. This is where "rare style" is born. It's about listening to the material and letting it guide the form.

This phase respects the ethical core of OCS by minimizing waste and honoring the value of the material. Complex cutting, draping, and zero-waste pattern making become expressions of the design philosophy.

What construction techniques elevate OCS fabrics?

- Draping & Bias Cutting: Using OCS silk-blend or fine cotton jersey on the bias creates a fluid, body-skimming silhouette that is both elegant and comfortable. It showcases the fabric's natural drape.

- Architectural Sewing: Use heavy OCS canvas or denim to create sharp, geometric seams, welded seams, or bonded finishes. The fabric's rigidity becomes part of the aesthetic.

- Texture Play: With textured weaves (jacquards, piqués), use minimal seaming to let the fabric itself be the decoration. Consider smocking, shirring, or trapunto quilting to add further dimension.

- Transformational Details: Design elements that change the garment's form—detachable collars, reversible construction, adjustable ties—add rarity and longevity, aligning with the sustainable ethos.

The technique must match the fabric's character. For a recent collaboration with a Tokyo-based brand, we used a stiff OCS organic cotton-linen canvas. The designer employed origami-inspired folding and minimal stitching, creating a jacket that was a wearable sculpture. The fabric's body was essential to the design.

How to handle trims and details for a rare design?

For a truly rare piece, every detail must be considered through the lens of the OCS narrative.

- Certified Trims: If you use a contrast fabric or binding, make it from the same or another OCS fabric. For example, bind the edges of an organic cotton jacket with a strip of organic silk noil.

- Embellishment Philosophy: If you add embroidery, use it sparingly and intentionally. Consider using OCS-certified organic cotton thread (though rare) or ensure any conventional thread is OEKO-TEX certified and its weight is factored into the final composition label.

- The Label as a Feature: Don't hide the OCS label. Make it a designed element—a woven jacquard label with your logo and the OCS icon, or an embroidered care instruction that's part of the interior aesthetic.

The goal is cohesion. The certification should feel like an intrinsic quality of the piece, not a sticker slapped on at the end.

Phase 3: The Narrative of Rarity – Marketing the Provenance

A rare design deserves a rare story. In the age of conscious consumption, the most compelling story is one of provenance and proof. The OCS certification is not a bureaucratic hurdle; it's the backbone of your product's biography. Your marketing should fuse the emotional appeal of the design with the forensic appeal of its traceability.

This narrative becomes your defense against fast-fashion imitation and your connection to a discerning clientele.

How to communicate OCS certification in a luxury context?

The language must shift from "sustainable" (which can sound generic) to "verifiably exceptional."

- Focus on Quality: "This dress is crafted from an exclusive OCS-certified extra-long staple cotton, selected for its unparalleled luster and strength. The certification ensures the fiber's purity from seed to cloth."

- Highlight Exclusivity: "The jacquard weave in this jacket was developed in a limited run of 800 meters with our fabric partner, Fumao, and is fully traceable via its OCS certificate."

- Offer Proof On-Demand: Provide a simple way (QR code, unique URL on the care label) for the buyer to access the redacted OCS Transaction Certificate for their specific garment's batch. This is the ultimate luxury in an age of doubt: total transparency.

This approach attracts a customer who values both design innovation and intellectual honesty. They are buying a story they can verify.

Can rare OCS design command a true luxury price point?

Without question. The price equation changes:

- Cost+: Premium rare fibers + custom development costs + low-volume production + certification integrity.

- Value Proposition: Exclusive design + proprietary material + ethical provenance + verifiable story.

This combination supports prices found in contemporary luxury or avant-garde segments. The OCS certification elevates the proposition from "expensive clothing" to "investible artifact with a clear conscience." A Berlin-based designer we work with sells her OCS organic wool-coat dresses at a €1200+ retail price. Her clients buy into the complete narrative of rare material, flawless construction, and transparent ethics.

The Commercial Reality: Production and Partnership

Executing rare designs with OCS fabrics requires a symbiotic partnership with a manufacturer who is both a technical expert and a guardian of certification integrity. Your production runs will be smaller, your oversight more hands-on, and your timeline more generous.

This is not fast fashion. It's slow, intentional, and precise creation.

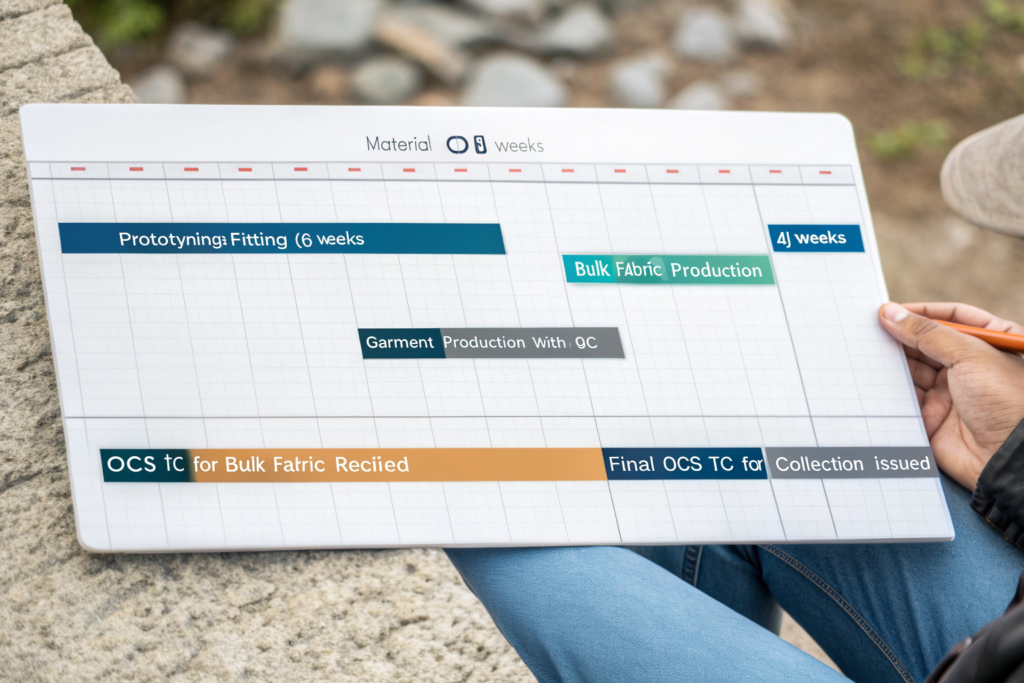

What are realistic expectations for MOQ and timeline?

Be prepared for a different scale:

- Fabric MOQ: For custom developed fabrics, 1000-3000 meters is standard. This may translate to 200-600 garments, depending on style.

- Garment MOQ: A factory specializing in this niche may accept 300-500 pieces per style.

- Timeline: Add 3-4 months for fabric development and sampling before bulk production even begins. Rushing this process compromises both design and certification.

Finding a factory that accepts these parameters and understands OCS is key. They exist, but they are not the giant garment mills. They are agile, technically skilled partners.

How to protect your rare design IP in this process?

Work with partners who respect IP. Have clear contracts:

- Exclusivity Agreements: For custom-developed fabrics, contract for exclusive use for a period (e.g., 2 seasons).

- Non-Disclosure Agreements (NDAs): Standard for sharing designs.

- Choose Integrity: The best protection is working with a supplier whose business model isn't based on copying clients. Their reputation is their guarantee.

Conclusion

Designing rare style clothing with OCS-certified fabric is the ultimate act of modern design integrity. It rejects the false choice between aesthetics and ethics, instead forging a new path where breathtaking design is inextricably linked to verifiable responsibility. It challenges designers to innovate at the material level, to master construction with intention, and to craft a narrative of provenance that is as compelling as the silhouette itself.

This is the future of meaningful fashion: pieces that are rare not just in appearance, but in their very DNA—from the certified field where the fiber grew to the final, stunning stitch.

If you are a designer ready to explore the limitless potential of certified fabrics as your medium, you need a manufacturing partner who is both a technician and a curator. At Shanghai Fumao, our vertical expertise and commitment to OCS innovation are here to translate your most ambitious visions into verifiable reality. Contact our Business Director, Elaine, to begin the conversation: elaine@fumaoclothing.com. Let's create something truly rare, together.