Struggling to choose between graphene and PCM cooling technologies for your summer collection? You're not alone. Many brands jump on the cooling fabric trend only to discover their chosen technology doesn't perform as expected in real-world conditions. The wrong choice can lead to customer returns, negative reviews, and missed opportunities. At Fumao, we've conducted extensive testing on both technologies across various summer applications.

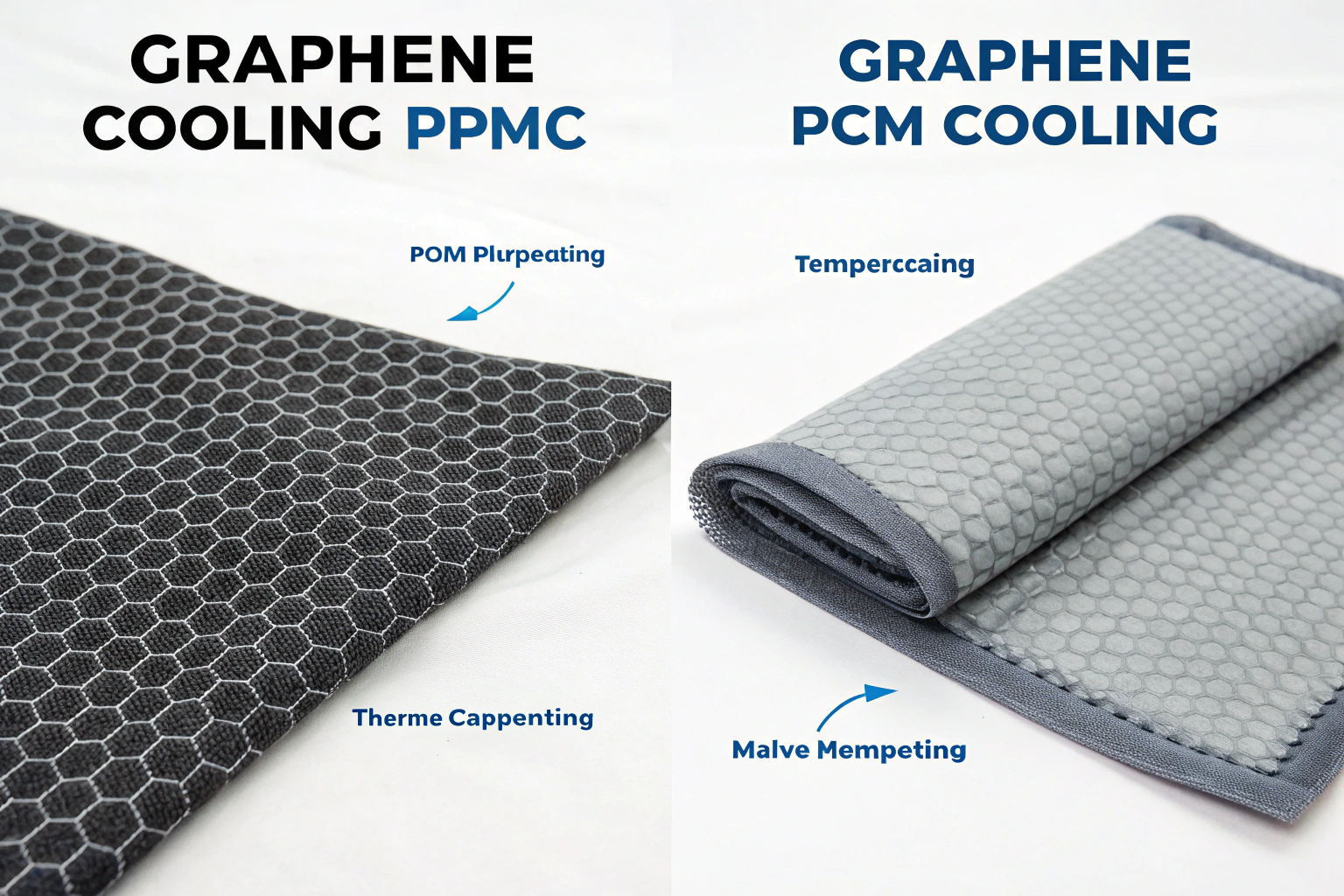

Choosing between graphene and PCM cooling fabrics depends on your specific performance requirements, budget, and target market. Graphene excels at continuous temperature regulation through superior thermal conductivity, while PCM (Phase Change Material) provides active cooling through heat absorption during phase transitions. Graphene works best for consistent cooling throughout wear, while PCM offers targeted cooling during heat spikes but has limited duration.

Understanding the distinct mechanisms and applications of each technology will help you select the right solution for your specific summer wear products. Let's examine how to make an informed decision based on performance data and practical considerations.

What Are the Fundamental Cooling Mechanisms of Each Technology?

Graphene and PCM cool through completely different physical principles. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, achieves cooling primarily through its exceptional thermal conductivity—approximately 5,000 W/mK, far superior to any traditional textile material. This property allows graphene-enhanced fabrics to rapidly dissipate body heat across the entire garment surface, creating an even cooling effect without cold spots.

PCMs work through latent heat absorption. These microencapsulated materials (typically paraffin-based hydrocarbons) remain solid until they reach their specific melting point (usually 24-28°C for summer wear). As the PCM melts, it absorbs substantial heat energy from the body, creating a noticeable cooling sensation. Once melted, the cooling effect diminishes until the PCM resolidifies, which requires exposure to cooler environmental temperatures.

How Does Graphene's Thermal Conductivity Create Cooling Effects?

Graphene's two-dimensional structure enables phonons (heat vibrations) to travel extremely efficiently across its surface. When incorporated into fabrics, graphene forms thermal conduction pathways that pull heat away from the body and distribute it throughout the garment. This continuous heat redistribution prevents localized hot spots and maintains a consistent microclimate next to skin. The cooling effect is passive but persistent—it works as long as there's a temperature difference between body and environment. Advanced graphene fabrics can reduce perceived temperature by 2-4°C consistently throughout wear, making them ideal for prolonged summer activities.

What Are the Phase Change Dynamics in PCM Cooling?

PCM cooling is fundamentally transient. The cooling intensity depends on the PCM's melting point, encapsulation quality, and concentration in the fabric. When skin temperature exceeds the PCM's melting point, the material absorbs 100-200 joules per gram as it transitions from solid to liquid. This provides intense cooling for 20-60 minutes, after which the PCM must resolidify to work again. The effectiveness depends on environmental conditions—PCM works best when temperatures fluctuate, allowing for repeated phase changes. Poorly encapsulated PCM can leak or degrade with washing, significantly reducing performance over time. Understanding phase change material technology in textiles helps predict real-world performance.

Which Technology Performs Best in Different Summer Conditions?

Performance varies dramatically based on environmental conditions and activity levels. Graphene's continuous cooling works best in consistently warm conditions with good air circulation, while PCM excels in environments with temperature fluctuations or for short-duration, high-intensity activities. Your choice should align with how and where customers will wear the garments.

For all-day summer office wear or casual clothing, graphene provides subtle, consistent cooling without the dramatic temperature swings of PCM. For athletic wear or situations involving movement between different temperature environments (outdoor to indoor), PCM's active cooling during heat spikes can feel more refreshing. However, PCM's limited duration means it may not support extended activities without "recharging" periods in cooler environments.

How Does Activity Level Impact Cooling Effectiveness?

Activity intensity dramatically affects cooling technology performance. During low-intensity activities (walking, casual wear), graphene maintains stable comfort by continuously dissipating mild metabolic heat. During high-intensity exercise, PCM initially provides superior cooling by absorbing sudden heat bursts, but may become saturated within 30-45 minutes. Graphene continues working regardless of activity level but may feel insufficient during extreme exertion. The table below shows performance characteristics:

| Activity Level | Graphene Performance | PCM Performance |

|---|---|---|

| Sedentary/Casual | Excellent consistent cooling | Moderate (minimal heat to absorb) |

| Light Activity | Very good continuous cooling | Good during activity peaks |

| High Intensity | Good base cooling | Excellent initial, fades later |

| Intermittent Activity | Good recovery between bouts | Excellent if environment cools between |

A California yoga wear brand found their customers preferred PCM for hot yoga classes (90-120 minutes) but chose graphene for all-day lifestyle wear, leading them to develop a dual-technology collection.

What Environmental Factors Most Affect Performance?

Environmental conditions significantly influence technology effectiveness. Graphene performs best with at least minimal air movement to carry away dissipated heat, making it ideal for breezy outdoor settings or ventilated indoor spaces. In completely still, humid conditions, its effectiveness decreases. PCM depends on temperature differentials—it works poorly if environmental temperatures remain consistently above the melting point, as the PCM cannot resolidify. High humidity reduces evaporative cooling from sweat, making both technologies feel less effective, though graphene's conduction-based cooling suffers less than PCM's phase-change mechanism.

What Are the Practical Application Considerations?

Beyond pure cooling performance, several practical factors influence technology selection. Durability, wash resistance, hand feel, and production scalability vary significantly between graphene and PCM applications. Understanding these practical considerations prevents surprises during production and ensures customer satisfaction through product lifespan.

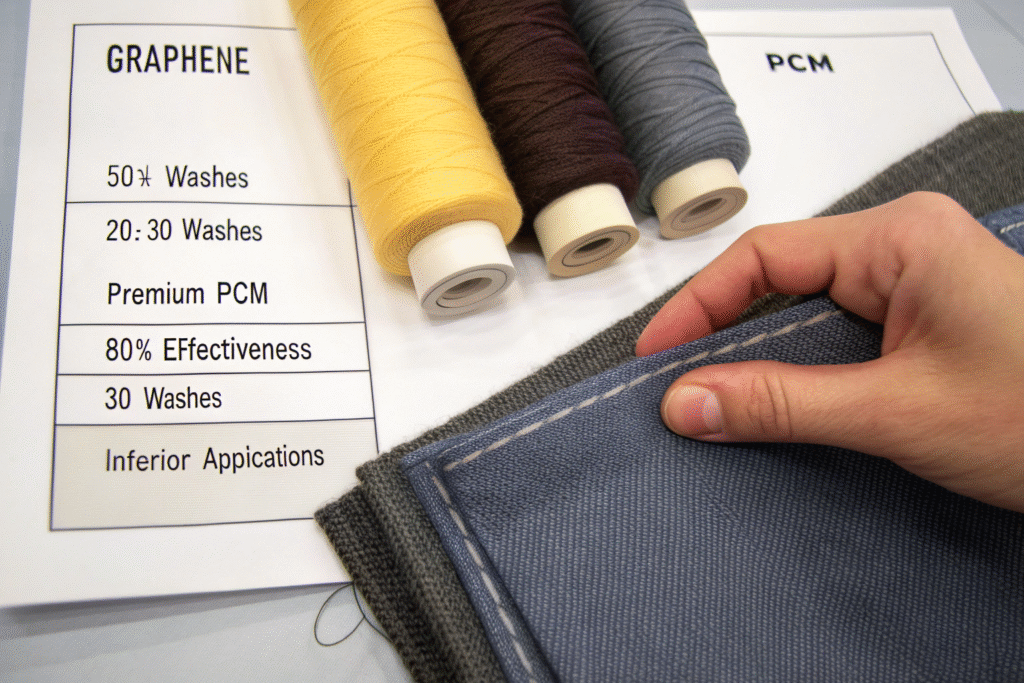

Graphene typically integrates into fabrics through coating, finishing, or incorporation into yarns during spinning. The application method affects durability—graphene-infused yarns generally withstand 50+ washes with minimal performance degradation, while coatings may deteriorate after 20-30 cycles. PCM primarily uses microencapsulation technology, where tiny PCM capsules bind to fibers or embed within them. Encapsulation quality determines durability—premium PCM treatments maintain 80% effectiveness after 30 washes, while inferior applications degrade rapidly.

How Do Durability and Wash Resistance Compare?

Long-term performance differs substantially. Graphene's carbon structure is inherently stable, providing consistent performance throughout the garment's lifespan when properly applied. We've tested graphene-infused fabrics showing less than 10% thermal conductivity reduction after 50 wash cycles. PCM durability depends entirely on encapsulation quality—premium microcapsules withstand repeated washing, while cheaper alternatives break, leak, or wash out. Poor PCM applications can lose 50% effectiveness after just 10 washes. Additionally, PCM has a finite number of phase change cycles (typically 1,000-5,000), after which the material degrades, while graphene has no such cycle limitation.

What Are the Cost and Production Implications?

Cost structures differ significantly. Graphene remains relatively expensive, adding $3-8 per meter to fabric cost depending on concentration and application method. PCM costs vary with quality but typically add $2-5 per meter. Production scalability also differs—graphene application often requires specialized equipment, particularly for yarn integration, while PCM application uses standard coating and finishing machinery with minor modifications. Minimum order quantities are typically higher for graphene fabrics due to specialized production requirements. A European fast-fashion brand successfully implemented PCM across their entire summer collection because the technology integrated easily with their existing production lines, while they reserved graphene for premium-priced items.

How Do You Verify Performance Claims and Quality?

With cooling technologies becoming marketing buzzwords, verifying performance claims is crucial. Both graphene and PCM have specific testing protocols to validate effectiveness and durability. Understanding these tests helps ensure you receive what suppliers promise and prevents disappointing customer experiences.

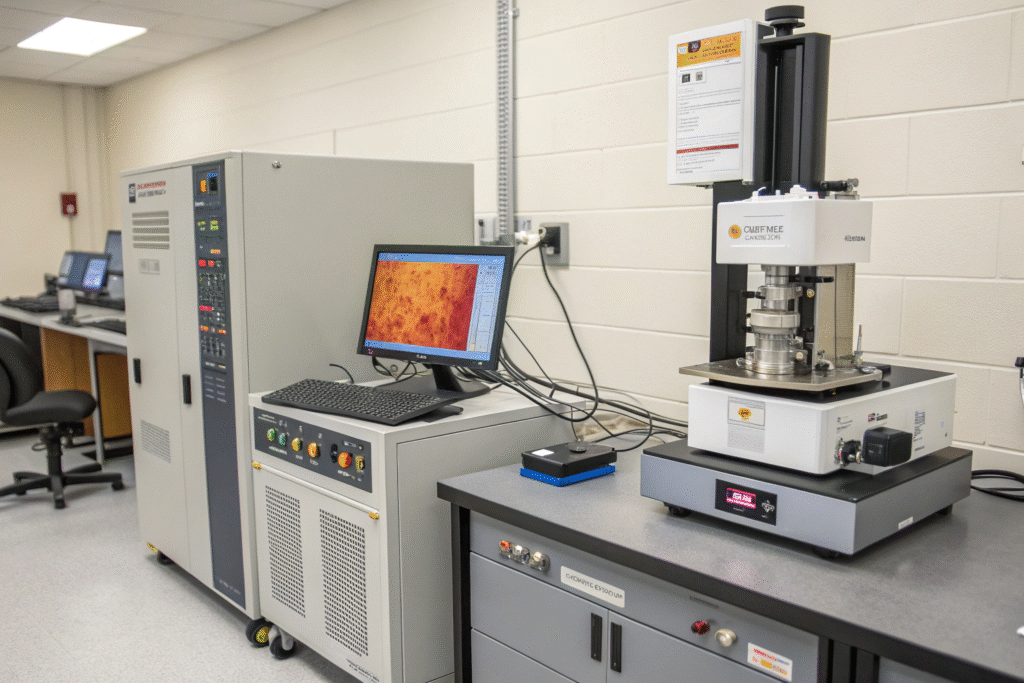

For graphene, thermal conductivity measurement using standardized methods (ASTM D5470, ISO 22007-2) provides quantitative performance data. Infrared thermography visually demonstrates heat distribution, showing graphene's uniform cooling effect. For PCM, differential scanning calorimetry (DSC) measures melting points, enthalpy (heat storage capacity), and cycling stability. Additionally, simulated wear trials with human subjects provide subjective comfort feedback that correlates with laboratory measurements.

What Laboratory Tests Validate Cooling Performance?

Standardized testing provides objective performance data:

- Thermal Conductivity Testing: Measures heat transfer rate through fabric (graphene)

- DSC Analysis: Quantifies PCM melting point and heat absorption capacity

- Thermal Manikin Testing: Simulates heat transfer from human body

- Wash Durability Testing: Measures performance retention after repeated laundering

- Microscopy Analysis: Verifies graphene distribution or PCM encapsulation quality

These tests should be conducted by independent laboratories for objectivity. We require suppliers to provide third-party test reports before approving materials for production. A Korean outdoor brand avoided a costly mistake when independent testing revealed their "graphene-enhanced" fabric contained insufficient graphene concentration to provide meaningful cooling effects.

How Can You Conduct Practical Performance Assessments?

Beyond laboratory tests, practical assessments provide real-world performance insights. Wear trials with temperature sensors and subjective comfort ratings help understand how technologies perform during actual use. Simple tests like placing fabric samples on warm surfaces and measuring temperature changes with infrared thermometers provide quick verification. For PCM, timing how long the cooling sensation lasts during wear and how quickly it recovers provides practical performance indicators. We've developed a standardized wear trial protocol that generates comparable data across different technologies and applications. Following established textile testing standards for smart fabrics ensures your assessment methodology is scientifically valid.

What Are the Emerging Hybrid and Advanced Options?

The most advanced cooling fabrics combine multiple technologies to overcome individual limitations. Graphene-PCM hybrids represent the cutting edge, offering both continuous heat distribution and active cooling during temperature spikes. These systems use graphene for base temperature regulation while PCM microcapsules provide additional cooling capacity during heat stress.

Newer technologies like bio-based PCMs derived from natural fats and plant oils offer improved sustainability profiles. Advanced graphene oxides and reduced graphene oxides provide similar cooling at lower costs, though with slightly reduced performance. Some manufacturers are developing triggered-release PCMs that activate at specific temperatures or moisture levels, providing more intelligent cooling response.

How Do Hybrid Systems Overcome Individual Limitations?

Graphene-PCM hybrids address the primary weakness of each technology alone. Graphene prevents PCM from feeling cold and clammy when not activated while ensuring continuous cooling when PCM is saturated. PCM provides the immediate cooling sensation that graphene lacks during sudden temperature increases. The combination creates a more comprehensive cooling experience that adapts to changing conditions. Production challenges include ensuring even distribution of both technologies and maintaining fabric hand feel. We've developed a proprietary hybrid application that maintains fabric drape and comfort while providing superior cooling performance across diverse conditions.

What Sustainable Options Are Emerging?

Sustainability concerns drive development of eco-friendly cooling technologies. Bio-based PCMs from renewable sources offer comparable performance to petroleum-based versions with better environmental profiles. Graphene production methods are evolving to reduce energy consumption and chemical usage. Some manufacturers offer recycled graphene from industrial waste streams. Additionally, new application methods reduce water and energy consumption during fabric treatment. A Scandinavian sustainable brand successfully marketed bio-PCM summer wear as part of their circular economy initiative, achieving premium pricing while maintaining performance standards.

Conclusion

Choosing between graphene and PCM cooling technologies requires careful consideration of your specific product requirements, target market, and performance expectations. Graphene excels for consistent, durable cooling in prolonged warm conditions, while PCM provides intense, temporary cooling ideal for intermittent heat exposure. Hybrid systems offer the most comprehensive solution but at higher cost and complexity.

The optimal choice depends on your customers' typical usage patterns, environmental conditions, and performance expectations. Consider conducting pilot tests with both technologies before full commitment to ensure the selected solution meets your specific needs. If you need guidance selecting the right cooling technology for your summer collection, our technical team can provide data-driven recommendations based on your specific requirements. We've helped numerous brands successfully implement cooling technologies that enhance customer satisfaction and brand value. For personalized advice and technical support, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let us help you create summer wear that genuinely keeps customers cool and comfortable.