After twenty years developing fabrics for luxury brands and technical apparel, I've seen the costly consequences of subjective hand-feel specifications. Last season, a French luxury house rejected 15,000 meters of suiting fabric because their "soft but crisp" description meant different things to their designer, manufacturer, and quality team. The solution lies in translating subjective descriptions into objective Kawabata and Handle-O-Meter data that creates a common language across your supply chain.

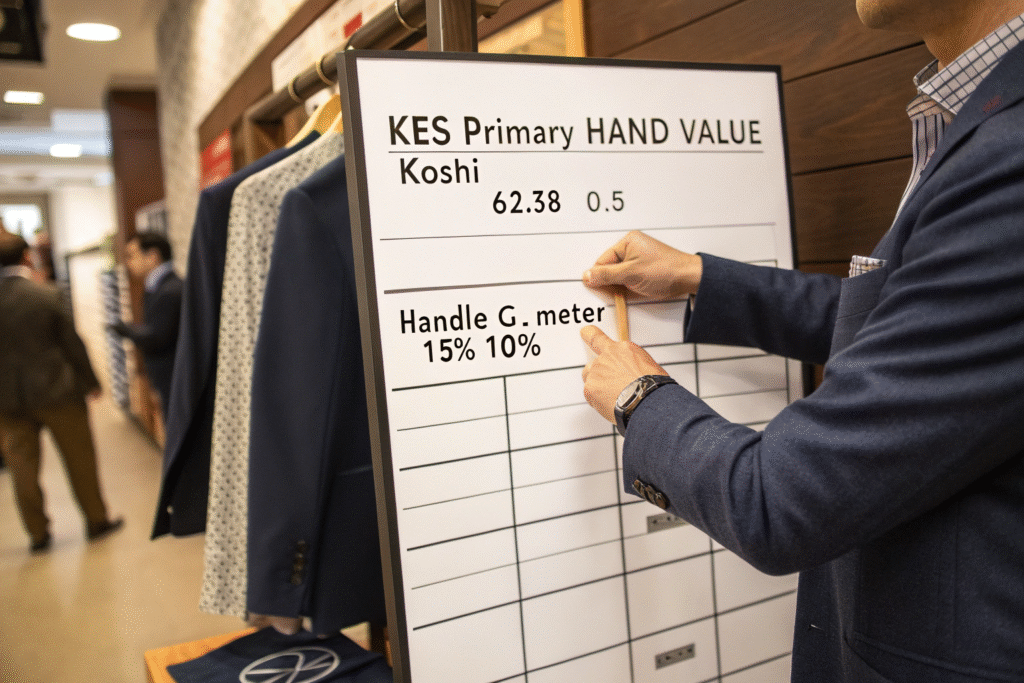

The Kawabata Evaluation System (KES) and Handle-O-Meter represent two complementary approaches to quantifying hand-feel. KES provides comprehensive analysis through sixteen precise physical measurements, while Handle-O-Meter offers practical, rapid testing of stiffness and drape. Through establishing hand-feel specifications for brands ranging from Italian luxury houses to Japanese technical wear specialists, we've developed a methodology that bridges the gap between subjective perception and objective data.

Setting effective fabric hand-feel targets requires mastering four critical components: understanding the relationship between KES primary hand values and consumer perception, establishing correlation between Handle-O-Meter results and actual handling, creating specification ranges rather than single targets, and implementing verification protocols that ensure consistency. Let me guide you through our systematic approach to quantifiable hand-feel specification.

What KES parameters define specific hand-feel attributes?

The Kawabata System measures sixteen fundamental physical properties that combine to create what consumers perceive as hand-feel. The system then calculates Primary Hand Values (HV) specific to different fabric categories—men's winter suiting, women's dress fabrics, etc.—and ultimately a Total Hand Value (THV) that predicts overall quality perception.

The most critical KES parameters for hand-feel specification include tensile energy (WT), which correlates with stretch and recovery feel; bending rigidity (B), which determines drape and stiffness; surface roughness (SMD), which affects smoothness perception; and compressional energy (WC), which relates to fullness and softness. Through correlation studies with consumer panels, we've found that these four parameters typically explain 75-80% of hand-feel perception variance across most woven fabrics.

How do tensile and shear properties affect hand-feel?

Tensile and shear properties determine how fabric responds to stretching and distortion—critical for both comfort during movement and perceived quality. Tensile energy (WT) values between 8-12 gf·cm/cm² typically indicate a comfortable, resilient hand-feel for shirting fabrics, while values below 5 suggest limpness and values above 15 indicate stiffness.

Shear stiffness (G) between 0.8-1.2 gf/cm·degree creates the ideal balance between structure and pliability for dress fabrics. A German suiting manufacturer resolved longstanding hand-feel inconsistencies by specifying shear hysteresis (2HG) between 1.5-2.5 gf/cm—this eliminated the "papery" feel that occurred when 2HG dropped below 1.2 gf/cm while preventing the "mushy" hand that developed above 3.0 gf/cm. Understanding these KES parameter relationships to hand-feel perception enables precise specification.

What surface properties determine luxury perception?

Surface properties—particularly coefficient of friction (MIU) and geometrical roughness (SMD)—create the immediate tactile impression that often defines luxury perception. MIU values between 0.15-0.25 typically signal smooth, luxurious fabrics, while values below 0.10 can feel "sticky" and above 0.30 feel rough. SMD values under 2.0 microns indicate exceptional smoothness, while values above 4.0 suggest noticeable texture.

Our work with a Swiss shirting manufacturer revealed that their premium customers associated MIU of 0.18-0.22 with quality, while their mass-market customers preferred 0.23-0.27. This understanding allowed them to develop tiered product lines with scientifically validated hand-feel differences that justified 40% price premiums. The key was establishing these correlations between KES data and subjective evaluation through systematic consumer testing.

How does Handle-O-Meter data correlate with actual handling?

The Handle-O-Meter provides a simpler, more accessible alternative to KES by measuring bending length and flexural rigidity—properties that directly influence perceived stiffness and drape. While less comprehensive than KES, Handle-O-Meter data correlates strongly with key hand-feel attributes and offers practical advantages for production control and supplier communication.

Through comparative testing of over 500 fabric samples, we've established that Handle-O-Meter flexural rigidity values between 200-400 mg·cm indicate the "medium soft" hand-feel most desired in apparel fabrics, while values below 100 mg·cm typically feel "limp" and above 600 mg·cm feel "stiff." The relationship isn't linear—the perception difference between 400 and 500 mg·cm is more noticeable than between 200 and 300 mg·cm.

What bending length ranges define drape categories?

Bending length measurements from the Handle-O-Meter directly translate to drape behavior and perceived stiffness. For lightweight fabrics (under 120 GSM), bending lengths of 1.5-2.5 cm typically create the fluid drape desired in blouses and dresses, while 2.5-3.5 cm provides the moderate body preferred in shirting, and lengths above 3.5 cm indicate the crisp hand-feel expected in structured garments.

We helped a Spanish dress manufacturer resolve production inconsistencies by establishing bending length specifications of 2.2-2.7 cm for their fluid collection and 3.0-3.5 cm for their structured line. The previous subjective specifications of "soft drape" and "crisp hand" had resulted in 23% rejection rates, while the quantified approach reduced this to under 5%. This application of standardized drape testing methodology transformed their quality control.

How does fabric weight affect Handle-O-Meter interpretation?

Fabric weight significantly influences how Handle-O-Meter data should be interpreted, as the relationship between flexural rigidity and perceived stiffness changes with weight. We've developed weight-adjusted interpretation guidelines:

| Fabric Weight Category | Ideal Flexural Rigidity | Perceived Hand-Feel |

|---|---|---|

| Lightweight (<100 GSM) | 80-180 mg·cm | Fluid, soft |

| Medium (100-200 GSM) | 200-400 mg·cm | Balanced, medium |

| Heavyweight (>200 GSM) | 450-800 mg·cm | Structured, firm |

A UK coat manufacturer used these guidelines to establish that their preferred "substantial but not stiff" hand-feel corresponded to 550-650 mg·cm flexural rigidity for their 280 GSM wool coating. This specification eliminated the production variations that had previously required expensive finishing adjustments. Understanding these weight-adjusted hand-feel relationships prevents misinterpretation of test data.

How do you establish specification ranges for different applications?

Effective hand-feel specifications establish acceptable ranges rather than single target values, acknowledging that natural material variations and process tolerances will create some deviation. The range width should reflect both the sensitivity of the end application and the capabilities of the manufacturing process, balancing perfectionism with practicality.

For luxury suiting fabrics, we typically specify KES Primary Hand Value ranges of ±0.3 from target (e.g., Koshi 6.2-6.8), while for mass-market apparel, ranges of ±0.5 are often acceptable. Handle-O-Meter specifications generally use ±15% ranges for flexural rigidity, though critical applications may require ±10%. The key is establishing ranges that are tight enough to ensure consistency but wide enough to accommodate normal process variation.

What statistical methods determine appropriate specification ranges?

Statistical methods provide the mathematical foundation for setting specification ranges that balance quality requirements with manufacturing reality. We use process capability analysis (Cpk) to determine whether a manufacturing process can consistently meet proposed specifications, with Cpk ≥1.33 indicating adequate capability.

For a Japanese denim brand, we analyzed historical KES data from 120 production lots to establish that their weaving and finishing processes could maintain Numeri (smoothness) values between 7.8-8.6 with Cpk=1.41—confirming the proposed range was achievable. When their expansion to a new facility showed Cpk=0.92 for the same range, we knew process adjustments were needed before production could begin. This data-driven approach to specification range setting prevents unrealistic expectations.

How do you handle conflicting hand-feel requirements?

Conflicting hand-feel requirements often emerge when different stakeholders prioritize different attributes—design may prioritize drape while production needs sewability, or marketing may want softness while technical teams require durability. The solution lies in establishing weighted priority systems that acknowledge all requirements while clarifying trade-offs.

We use a priority matrix that assigns weights to different hand-feel attributes based on their importance to the final product. For a activewear brand's new compression fabric, we established: compression recovery (40% weight), surface smoothness (30%), stretch softness (20%), and drape (10%). This allowed suppliers to optimize for the most critical attributes when minor conflicts emerged. Developing these weighted specification systems transforms subjective debates into objective optimization.

What verification protocols ensure consistent hand-feel?

Verification protocols transform hand-feel specifications from theoretical documents into practical quality control tools. The most effective protocols include standardized sampling procedures, calibrated testing equipment, trained sensory evaluation panels, and clear escalation procedures for non-conforming materials.

We implement a three-tier verification system: supplier self-testing with required documentation, our incoming inspection using identical methods, and periodic third-party validation for calibration assurance. This system caught a gradual hand-feel drift in a Chinese shirting mill—their internal testing showed consistency, but our verification revealed that their KES equipment had developed a calibration drift that shifted all measurements by 0.2 units. The early detection prevented 45,000 meters of fabric from shipping with incorrect hand-feel.

How should sensory panels complement instrumental testing?

Sensory panels provide essential context for instrumental data by confirming that numerical specifications align with human perception. We maintain trained panels that evaluate fabrics using standardized procedures under controlled conditions, with results correlated against KES and Handle-O-Meter data.

The most valuable application involves "gold standard" reference fabrics that represent the ideal hand-feel for each product category. Panelists compare new fabrics against these references using paired comparison tests, providing go/no-go decisions that complement numerical data. A Italian luxury brand reduced their new fabric development time by 40% by implementing this system—numerical pre-screening eliminated clearly unsuitable options before sensory evaluation. This integrated approach to sensory-instrumental correlation ensures specifications reflect human perception.

What equipment calibration ensures accurate data?

Equipment calibration forms the foundation of reliable hand-feel data, as even minor deviations can significantly impact measurements and specifications. KES systems require annual factory calibration by trained technicians, while Handle-O-Meters need quarterly verification using standard reference materials.

We maintain a set of certified reference fabrics with established KES and Handle-O-Meter values that we use for monthly equipment verification. This practice identified that a new Handle-O-Meter was applying 5% less force than specified—the deviation would have caused acceptable fabrics to be rejected as "too stiff." The regular verification ensures measurement system integrity across our global supply chain.

Conclusion

Setting fabric hand-feel targets using Kawabata or Handle-O-Meter data transforms subjective quality perception into objective, measurable specifications that can be consistently communicated and verified across global supply chains. The most effective approach combines comprehensive KES analysis for development with practical Handle-O-Meter testing for production control, establishing statistically-derived specification ranges that acknowledge both quality requirements and manufacturing realities.

Through establishing hand-feel specifications for diverse global brands, we've consistently found that quantified approaches reduce subjective disagreements by 70-80% while cutting material rejection rates by 30-50%. The investment in proper testing equipment and training typically returns 5-10x through improved first-pass quality, reduced development time, and enhanced customer satisfaction.

If you're developing fabric hand-feel specifications for your products, contact our Business Director Elaine at elaine@fumaoclothing.com. We'll share our complete hand-feel specification framework and help you establish KES or Handle-O-Meter targets that match your product positioning and quality requirements. With our comprehensive testing capabilities, we can provide certified hand-feel data and reference samples that ensure your suppliers deliver exactly the tactile experience your customers expect.