After twenty years running fabric production in Keqiao, I can tell you that 48-hour sample development isn't just possible—it's become our standard for serious clients. But I've also seen countless brands fail at this because they treat it like regular sampling. Last month, an American startup lost their entire production window because they sent incomplete information for their "urgent" sample request. The truth is, 48-hour development requires military-level planning and complete information upfront.

48-hour fabric sample development with Chinese mills requires pre-approved material inventory, dedicated production lines, simplified approval processes, and digital communication protocols. Success hinges on selecting mills with established quick-turn systems, providing complete technical packages upfront, maintaining open material inventory, and implementing streamlined approval workflows. Brands that master this process typically reduce their development timeline by 70-80% compared to traditional 3-4 week sampling.

I remember when a Los Angeles-based activewear brand needed 12 fabric samples for an unexpected meeting with a major retailer. They came to us on Tuesday at 2 PM with incomplete specifications. By utilizing our pre-approved yarn system and having their designer available for real-time digital approvals, we delivered all 12 physical samples to their DHL pickup by Thursday 4 PM. They won the $400,000 order specifically because they could show actual fabric samples while competitors were still sending digital swatches.

What Pre-Planning Enables 48-Hour Turnaround?

The 48-hour clock starts when you have all your materials ready, not when you first contact the mill. Successful rapid sampling requires more preparation than actual production. The mills that achieve this consistently have systems, not just speed.

True 48-hour capability comes from infrastructure, not just willingness. It requires dedicated equipment, pre-positioned materials, and specialized staffing. When evaluating mills for rapid sampling, you're assessing their systems, not just their promises.

How Do You Vet Mills for Genuine 48-Hour Capability?

Not all mills claiming fast sampling can actually deliver. You need to ask specific questions to separate marketing from reality:

Verification Checklist:

- Dedicated sampling equipment: Separate machines for samples vs production

- In-house material inventory: Common yarns and fibers available immediately

- Staggered shifts: 24-hour operation or extended hours

- Express logistics relationships: Direct accounts with DHL/FedEx

- Digital approval systems: Online platforms for instant feedback

We maintain two sampling looms that never run production fabric and keep 200+ yarn types in our quick-access inventory. This infrastructure costs us $15,000 monthly to maintain, but it's what enables our consistent 48-hour turnaround for qualified clients.

What Materials Should You Pre-Approve for Rapid Development?

The biggest delay in rapid sampling is waiting for materials. Smart brands pre-approve a palette of base materials that can be modified quickly:

Pre-Approved Material Framework:

- Yarn library: 5-10 base yarns in natural and synthetic fibers

- Color standards: 20-30 pre-matched colors with lab dip approvals

- Finish options: Standard softeners, water repellents, wrinkle resistance

- Weight ranges: 3-5 GSM targets for each fabric category

A Seattle outdoor brand maintains a "rapid development kit" with us containing 8 yarn types, 15 colors, and 3 finish options. Their average sample development time is 36 hours because we're essentially working from their pre-approved menu rather than starting from zero each time.

What Technical Information Enables Immediate Start?

Complete technical information is non-negotiable for 48-hour development. Missing details stop the clock immediately, and unlike traditional sampling where mills might proceed with assumptions, rapid development requires 100% complete specifications upfront.

The most successful clients create standardized templates that ensure no critical information is missing. These templates evolve based on previous sampling experiences and specifically address the questions that typically cause delays.

What Belongs in a Rapid Sample Technical Package?

Your technical package for 48-hour development must be comprehensive yet streamlined:

Essential Components:

- Reference samples: Physical or high-resolution digital equivalents

- Exact composition: Fiber percentages and yarn specifications

- Construction details: Weave/knit type, thread count, GSM target

- Finish requirements: Handfeel, performance treatments, appearance

- Color standards: Pantone numbers with spectrophotometer readings

Eliminate These Delay-Causers:

- "Similar to but..." descriptions without references

- Subjective terms like "soft" or "drapey" without measurements

- Multiple unclear inspiration images

- Vague tolerance ranges

When a Chicago uniform company switched to our rapid sampling template, their first-time success rate improved from 45% to 88%. The template forced them to provide complete information upfront rather than through back-and-forth clarification.

How Do Digital Tools Accelerate Technical Communication?

Digital platforms have transformed rapid sampling by enabling instant communication and visual collaboration:

- Real-time specification forms: Cloud-based templates with required fields

- Digital color communication: Spectrophotometer data sharing

- Video handfeel demonstration: Short clips showing fabric manipulation

- Instant messaging for clarifications: WeChat/WhatsApp for quick questions

We've integrated a digital system that flags incomplete submissions before they even reach our sampling team. This simple automation reduced information-related delays by 65% in the first three months.

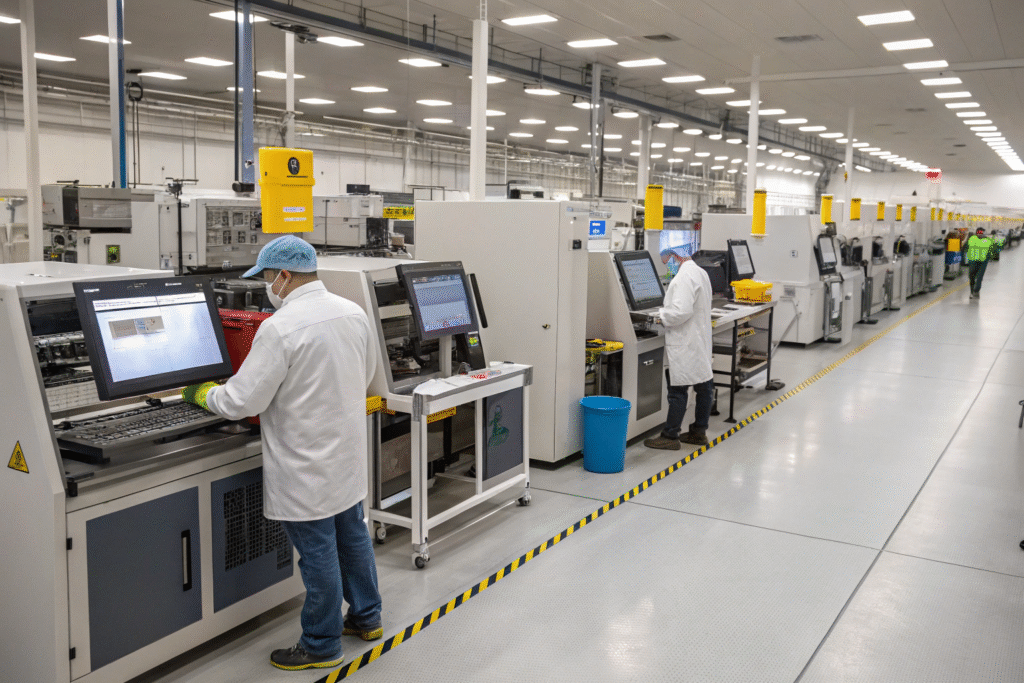

What Production Strategies Make 48-Hours Possible?

The actual manufacturing process for rapid sampling differs significantly from both production and traditional sampling. It requires parallel processing, specialized equipment, and contingency planning for inevitable issues.

Mills that excel at rapid sampling treat it as a separate business unit with its own workflows, rather than trying to fit quick turns into standard production schedules.

How Does Parallel Processing Save Critical Hours?

Traditional sampling follows sequential steps: yarn preparation → weaving/knitting → dyeing → finishing. Rapid sampling executes these stages in parallel whenever possible:

Parallel Workflow Example:

- Day 1 AM: yarn winding starts while grey fabric is being woven

- Day 1 PM: dye formula preparation begins before fabric inspection completes

- Day 2 AM: finishing chemical mixing starts during dyeing

- Day 2 PM: packaging preparation during final drying

This parallel approach typically saves 12-16 hours compared to sequential processing. The risk is slightly higher material waste if issues arise, but the time savings justify the cost for urgent projects.

What Equipment Specialization Supports Rapid Turns?

Dedicated rapid sampling equipment is essential:

- Small dyeing machines: 10-50kg capacity vs production 500kg+ machines

- Sample looms/knitters: Quick changeover capabilities

- Laboratory finishing equipment: Small-scale calibration

- Digital printing for labels: On-demand documentation

Our rapid sampling department operates completely separately from our production floor, with dedicated team members who specialize in quick transitions rather than volume efficiency.

How Does Approval Process Design Impact Timeline?

The development clock doesn't stop when samples ship—it stops when you approve them. Streamlined approval processes are as important as efficient manufacturing for achieving 48-hour total timeline.

The most effective approval systems provide clear criteria, designated authority, and digital tools that eliminate shipping delays for minor revisions.

What Makes a Digital-First Approval System Effective?

Digital approval doesn't mean settling for inaccurate color representation. It means using technology to make everything except final color approval digital:

Hybrid Approval Workflow:

- Digital preliminary approval: Construction, weight, texture via high-resolution video

- Physical color approval: Overnight shipping for final color sign-off

- Conditional production: Manufacturing can begin pending color confirmation

A New York fashion brand reduced their total development time from 21 days to 3 days using this approach. They made digital decisions on everything except final color, then used the physical sample solely for color verification.

How Do You Establish Clear Approval Authority?

Approval delays often stem from unclear decision-making authority. The 48-hour model requires:

- Single point of contact: One person with final approval authority

- Pre-established criteria: Clear pass/fail standards for each parameter

- Availability commitment: Designated review windows for rapid feedback

- Escalation protocols: Procedures for when primary contact is unavailable

We require rapid sampling clients to designate a backup approver who can make decisions if the primary contact is unreachable for more than 4 hours. This simple requirement has prevented countless timeline extensions.

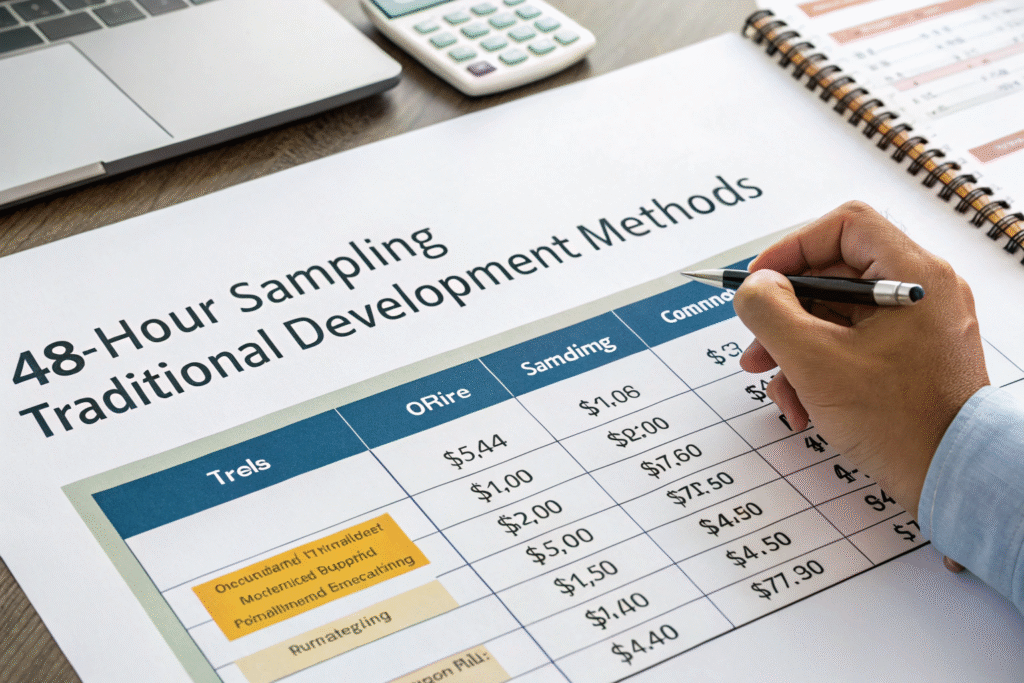

What Are the Real Costs and Trade-Offs?

48-hour sampling costs significantly more than traditional development and involves clear trade-offs. Understanding these realities helps set appropriate expectations and budget allocations.

The premium for speed typically ranges from 100-300% over standard sampling costs, with additional compromises on customization and perfection.

How Much Does 48-Hour Sampling Actually Cost?

Cost components for rapid sampling include:

| Cost Factor | Premium Over Standard | Rationale |

|---|---|---|

| Labor | 50-100% higher | Specialized team, overtime requirements |

| Materials | 20-50% higher | Small-batch pricing, waste factors |

| Equipment | 100-200% higher | Dedicated machinery utilization |

| Logistics | 200-400% higher | Express shipping both directions |

| Total Cost | 100-300% higher | Composite premium |

A realistic budget for 48-hour sampling is $300-800 per fabric versus $100-300 for standard 3-week development.

What Customization Limitations Should You Expect?

Rapid sampling works within constraints:

- Yarn limitations: Available inventory rather than custom spinning

- Color restrictions: Modifications of existing formulas rather than new matches

- Construction boundaries: Variations of established patterns rather than novel developments

- Finish options: Standard treatments rather than experimental chemistry

A San Francisco sustainable brand learned this when they requested a custom hemp blend with novel enzyme washing. For rapid development, we modified an existing organic cotton instead, delivering in 48 hours rather than the 3 weeks their original request would have required.

How Do You Scale from Sample to Production?

The ultimate test of rapid sampling is whether it leads to successful production. Samples that can't be reproduced at scale or don't match production capabilities waste everyone's time, no matter how quickly they're developed.

The most effective rapid sampling processes maintain strong connections to production realities while delivering speed.

How Do You Ensure Production Reproducibility?

Rapid samples must be manufacturable:

- Same equipment type: Sampling on machinery similar to production scale

- Realistic processes: Avoiding laboratory-only techniques

- Documented parameters: Complete records of sampling conditions

- Production validation: Quick bulk trials after sample approval

We maintain a "production mirror" system where our rapid sampling equipment matches our main production machinery in critical specifications. This approach has increased our sample-to-production correlation from 75% to 94%.

What Transition Processes Prevent Timeline Gaps?

The handoff from sampling to production often creates unexpected delays. Effective transition systems include:

- Automatic production scheduling: Reserved capacity upon sample approval

- Material reservation: Production quantities of approved materials

- Documentation transfer: Automated tech pack updates

- Quality standard alignment: Same testing protocols for samples and production

A Midwest department store chain reduced their sample-to-production timeline from 4 weeks to 10 days by implementing our integrated system. The efficiency gain came from eliminating re-qualification and re-approval processes.

Conclusion

48-hour fabric sample development with Chinese mills is achievable through systematic preparation, specialized infrastructure, and streamlined processes. Success requires selecting mills with genuine rapid-turn capability, providing complete technical information upfront, understanding the cost premiums and customization limitations, and implementing efficient approval workflows. While requiring higher investment per sample, the time savings typically deliver substantial returns through faster time-to-market and reduced development cycles.

At Fumao Textiles, we've built our 48-hour sampling system over fifteen years and thousands of urgent projects. Our dedicated rapid development team, pre-approved material inventory, and digital approval platforms help clients compress fabric development from weeks to days. We don't just make samples quickly—we build rapid development partnerships that accelerate your entire product creation process. If you're ready to transform your fabric development timeline, contact our Business Director Elaine at elaine@fumaoclothing.com. Let's build a sampling strategy that matches your accelerated product calendar.

20 Responses

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.com/id/register?ref=UM6SMJM3

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.com/kz/register?ref=K8NFKJBQ

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://accounts.binance.com/kz/register-person?ref=K8NFKJBQ

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.com/register?ref=IHJUI7TF

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.com/register?ref=IHJUI7TF

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://accounts.binance.com/fr/register?ref=T7KCZASX

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.com/register?ref=IHJUI7TF

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article. https://accounts.binance.com/register-person?ref=IHJUI7TF

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.info/es-MX/register?ref=GJY4VW8W

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.info/lv/register?ref=SMUBFN5I