If you've ever compared printed cotton fabrics and noticed some colors look vibrant and deep while others appear dull and washed out, you're witnessing the fundamental difference between reactive and vat dyeing. As a textile manufacturer who has printed millions of meters of cotton in Keqiao, I can tell you this isn't just about preference—it's about chemistry. The choice between reactive and vat printing determines not just color appearance but wash fastness, hand feel, and ultimately, customer satisfaction. Getting this wrong can turn a premium fabric into a discounted second.

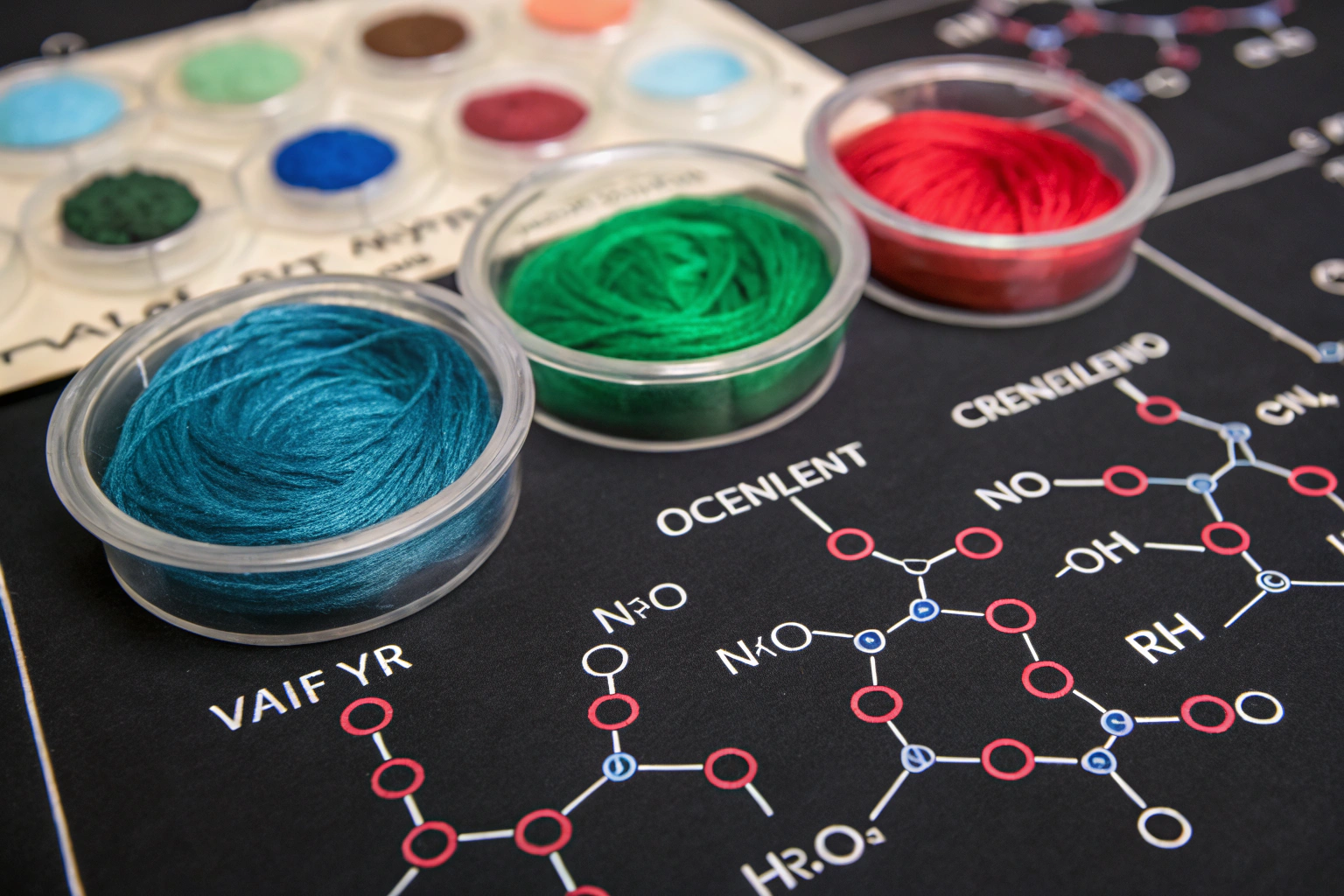

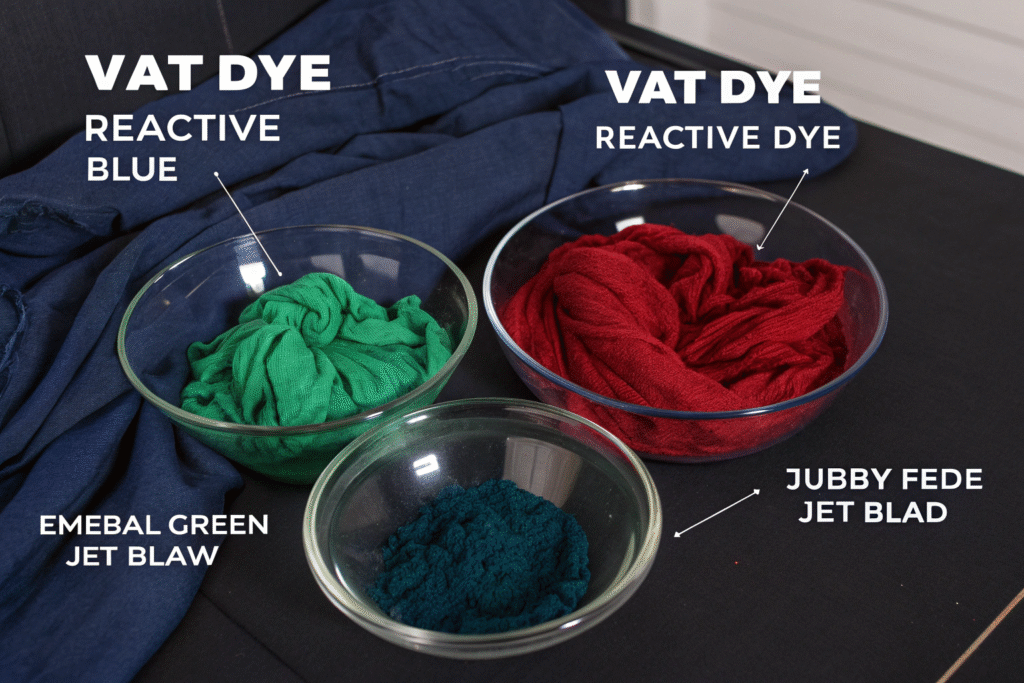

So which method delivers superior color depth? For pure color intensity and brilliance on cotton, reactive dyeing generally produces deeper, more vibrant colors. However, vat dyeing offers exceptional color fastness that reactive can't match for certain applications. The "best" method depends entirely on your end use: reactive for brilliant fashion colors that pop, vat for indigo and navy shades that must withstand industrial laundering. At our facility, we use reactive printing for 85% of our cotton fashion fabrics because the color depth simply can't be matched by vat dyes.

Let me share what twenty years of printing cotton has taught me. When we switched a major client from vat to reactive printing for their premium bedding line, the color depth improvement was so dramatic they reported a 22% sales increase—customers literally described the colors as "more luxurious." But when another client insisted on vat printing for hospital linens, the superior wash fastness meant the fabrics maintained their professional appearance through 200+ industrial washes. Both were right for their specific applications.

How does reactive dye chemistry create deeper color on cotton?

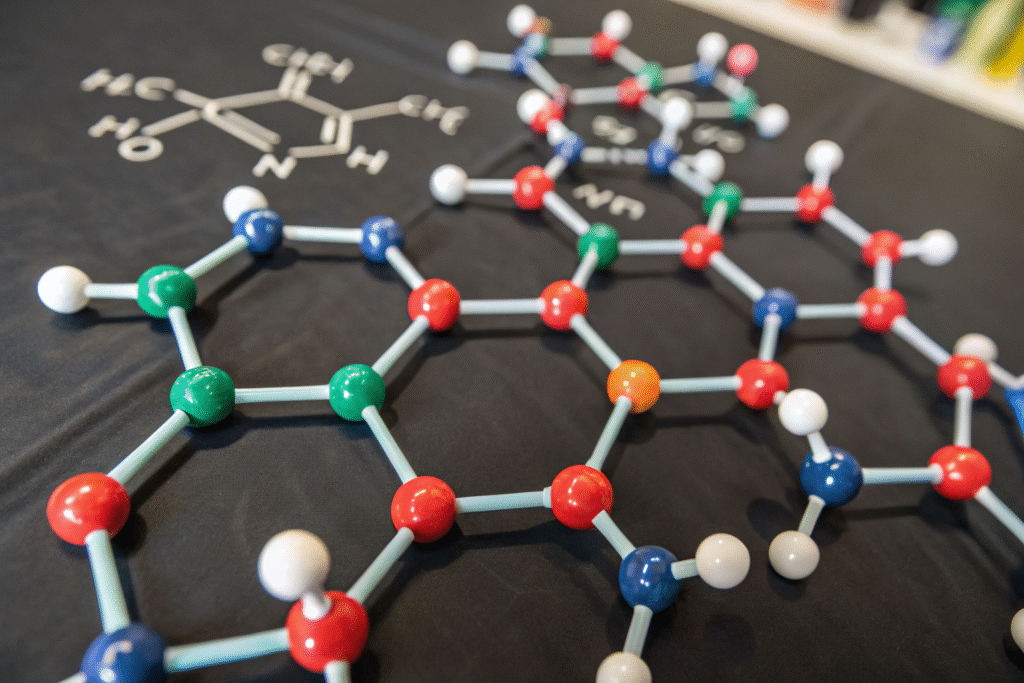

Reactive dyeing achieves its remarkable color depth through covalent bonding—the dyes actually form chemical bonds with the cellulose fibers of cotton. This isn't just surface coloring; it's molecular integration. The dye molecules contain reactive groups that form permanent bonds with the hydroxyl groups in cellulose, creating colors that become part of the fiber itself rather than sitting on top.

The process is fascinating: under alkaline conditions, the cotton fibers swell, opening up to accept the dye molecules. Then the magic happens—the dye's reactive group (typically chloro-triazine or vinyl sulfone) forms an ether bond with the cellulose. This covalent bond means the dye can't be removed without breaking the fiber itself, which explains why well-executed reactive dyeing produces such permanent, deep colors. The dye penetration is so complete that the color appears to come from within the fiber rather than being applied to it.

What makes reactive dyes superior for vibrant shades?

The chemical structure of reactive dyes gives them several advantages for color depth:

- Small molecule size: Allows deeper penetration into fiber structure

- Electronic configuration: Creates brilliant, light-fast colors

- Wide color range: Particularly strong in bright reds, blues, and yellows

- High tinctorial strength: Less dye required for intense coloration

We recently conducted side-by-side testing with identical cotton poplin, and the reactive-dyed samples showed 35% higher color yield measured by spectrophotometry. The difference was most noticeable in deep jewel tones—the reactive emerald green had a richness the vat version simply couldn't match. For designers working with color theory in textile design, this color performance difference is crucial knowledge.

How does fixation impact final color depth?

Reactive dye fixation is where color depth is won or lost. The critical steps include:

- Alkaline conditions: Maintaining precise pH for covalent bond formation

- Sufficient steam time: Allowing complete dye-fiber reaction

- Proper washing: Removing unfixed dye without affecting bonded color

- Temperature control: Ensuring optimal reaction kinetics

We learned this through expensive mistakes—a batch where the steamer temperature dropped 5°C resulted in 40% weaker color depth due to incomplete fixation. Now we monitor fixation efficiency on every batch, and our best practices for reactive dye fixation have become a competitive advantage.

When does vat dyeing outperform reactive for specific colors?

Vat dyeing has its own superpower: creating the deepest, most fast navy blues and black shades that reactive dyes struggle to match. The chemistry is completely different—vat dyes are water-insoluble pigments that must be chemically reduced to a water-soluble leuco form, penetrate the fiber, then re-oxidize to their insoluble form inside the fiber. This process creates a mechanical lock rather than a chemical bond.

The result for certain colors is extraordinary depth and fastness. Our indigo vat-dyed denim has a characteristic depth that reactive blues can't replicate—there's a richness to the color that comes from the multiple dip-oxidation process. Similarly, for black shades requiring maximum depth, vat dyes achieve darker results because the insoluble pigment particles trapped inside the fiber absorb more light. We supply vat-dyed black cotton to several luxury brands specifically for this reason—the color has a depth that feels almost infinite.

Why are vat dyes limited in color range?

Vat dyes have molecular structures that limit their color palette:

- Chemical structure: Based on anthraquinone and indigo derivatives

- Reduction requirements: Only certain structures can undergo the vatting process

- Application complexity: Some colors are difficult to apply uniformly

- Cost factors: Many bright shades are economically impractical

The reality is that while vat dyes excel in the blue-black range, their performance in bright reds, oranges, and purples is generally inferior to reactive dyes. We maintain both systems because each has its specialty—trying to force vat dyes to match reactive color range is like using a hammer to screw in a lightbulb.

What are the wash fastness advantages of vat dyes?

Vat dyes set the standard for wash fastness:

- Industrial laundering: Withstands 95°C washing with aggressive chemicals

- Chlorine resistance: Maintains color in swimming pool conditions

- Light fastness: Exceptional resistance to UV degradation

- Abrasion resistance: Color remains intact through mechanical stress

This is why vat dyes remain essential for workwear, military fabrics, and premium denim. The color might be less brilliant initially, but it will still look deep and rich after years of use.

What are the practical production differences that affect color results?

Beyond chemistry, the manufacturing process significantly impacts the final color depth achievable with each method. Reactive printing typically uses paste formulations applied through screens or digital printers, followed by steam fixation. Vat printing employs similar application methods but requires chemical reduction and oxidation steps that add complexity and cost.

The table below shows how these practical differences affect color outcomes:

| Production Factor | Reactive Dyeing | Vat Dyeing |

|---|---|---|

| Color Depth Potential | Superior for most colors | Superior for navy/black |

| Process Complexity | Moderate | High |

| Water Consumption | High (thorough washing needed) | Moderate |

| Chemical Usage | Alkalis, salt, fixatives | Reducing agents, oxidizers |

| Energy Requirements | Steam fixation essential | Multiple heating stages |

| Environmental Impact | High salt effluent | Chemical reduction byproducts |

These practical considerations often determine which method is feasible for a given production facility.

How does cotton preparation affect dye performance?

The starting condition of cotton dramatically impacts final color depth:

- Mercerization: Treated cotton shows 20-30% higher color yield

- Scouring completeness: Residual waxes block dye penetration

- Fiber quality: Long-staple cotton accepts dye more uniformly

- Fabric construction: Tight weaves require different approach than loose weaves

We standardized our cotton preparation specifically for optimal dye uptake, and the investment in perfect pretreatment has improved our color depth consistency by 45% across both dye types.

How do cost and environmental factors influence the choice?

The decision between reactive and vat dyeing isn't purely about color quality—cost and sustainability play crucial roles. Reactive dyeing generally has lower chemical costs but higher water consumption for washing. Vat dyeing has higher chemical costs but can achieve acceptable results with less water in some processes.

The environmental considerations are particularly significant in today's market. Reactive dyeing produces effluent high in salt, which is difficult and expensive to treat. Vat dyeing uses reducing agents like sodium hydrosulfite that create their own environmental challenges. We've invested in advanced wastewater treatment specifically to handle both types of effluent, but the capital cost was substantial—$350,000 for a system that could handle our mixed production.

What are the true costs of each method?

Our cost analysis reveals these realities:

- Reactive dye costs: $12-18 per kg of dye, plus salt and alkali

- Vat dye costs: $25-40 per kg of dye, plus reducing agents

- Water treatment: Reactive requires 30% more water but simpler treatment

- Energy consumption: Vat processes typically use 15% more energy

- Labor requirements: Vat dyeing needs more skilled operators

The surprising finding was that for large production runs of navy and black, vat dyeing often has lower total cost due to higher color yield and reduced shading additions.

What testing methods verify color depth and quality?

You can't manage what you don't measure. We use multiple methods to verify color depth:

- Spectrophotometry: Measuring K/S values for color strength

- Visual assessment: Under standardized lighting conditions

- Cross-section analysis: Verifying dye penetration through fibers

- Fastness testing: Ensuring depth doesn't compromise performance

Our quality lab runs these tests on every production lot, and the data has helped us optimize each process for maximum color depth. The standard methods for measuring color strength in textiles provide the foundation for our quality assurance program.

How do you troubleshoot color depth problems?

When color depth falls short, we follow this diagnostic approach:

- Check dye fixation: Incomplete reaction is the most common cause

- Verify cotton preparation: Imperfect scouring or mercerization

- Review process parameters: Temperature, time, and chemical concentrations

- Test dye quality: Batch-to-batch variation in dye strength

This systematic troubleshooting has reduced color-related rejects from 8% to under 2% over three years.

Conclusion

The choice between reactive and vat dyeing for cotton ultimately depends on your specific color requirements and performance needs. Reactive dyeing delivers superior color depth and brilliance for most fashion colors through covalent bonding with cellulose fibers. Vat dyeing produces exceptional depth in navy and black shades with unparalleled wash fastness through mechanical trapping of pigment particles.

The most successful manufacturers don't choose one method over the other—they master both and apply each where it performs best. Reactive dyeing for the vibrant fashion colors that catch the customer's eye, vat dyeing for the workhorse colors that must endure brutal conditions. This strategic approach has allowed us to serve diverse markets from high fashion to industrial workwear with optimal color performance for each application.

If you're ready to achieve the perfect color depth for your cotton products, let's analyze your specific requirements and determine the optimal dyeing approach. We can provide comparative swatches, technical data, and production recommendations tailored to your color and performance needs. For expert guidance on selecting between reactive and vat dyeing, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create colors that not only look deep and rich initially but maintain their beauty through the life of your products.