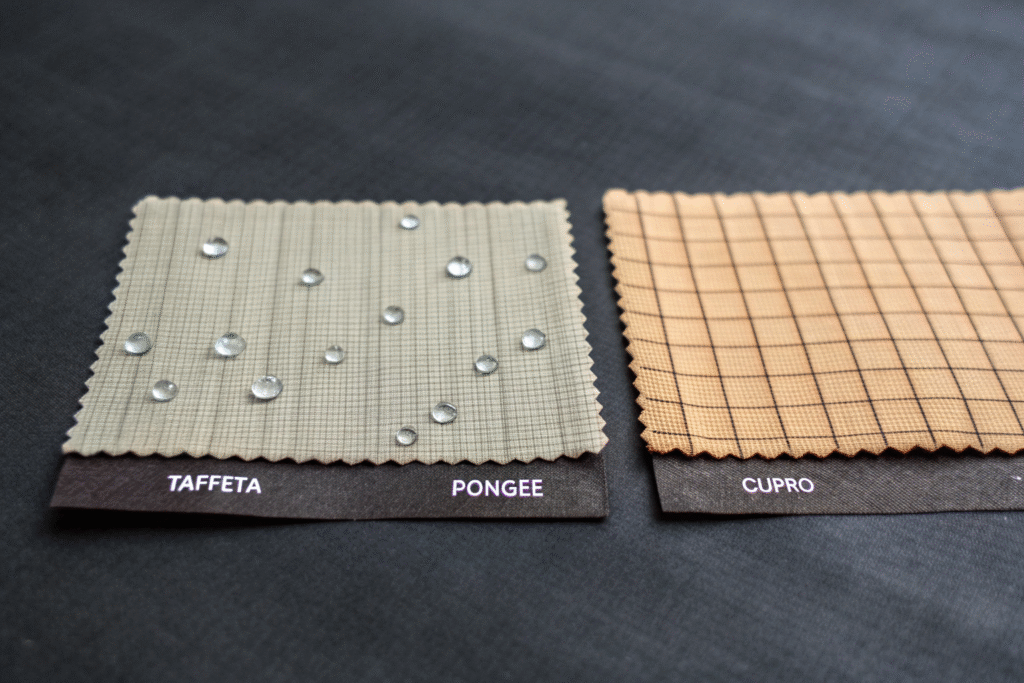

As a fabric manufacturer with over 20 years in the heart of China's textile district, I get this question all the time from American clients like Ron. You're not just buying a piece of cloth; you're investing in the comfort and performance of your final garment. Choosing the wrong lining can ruin an otherwise perfect design, leading to returns and unhappy customers. The battle for breathability often comes down to three main contenders: taffeta, pongee, and cupro.

So, which lining fabric breathes the best? For pure, high-performance breathability and moisture-wicking, cupro is the undisputed champion. It's a regenerated cellulose fabric known for its exceptional air permeability and silky feel. However, the "best" choice isn't that simple—it depends heavily on your application, budget, and desired balance between durability, cost, and comfort. Taffeta offers a robust, cost-effective shield, while pongee strikes a notable balance between breathability and price, making it a popular workhorse.

Let's break down this complex decision. We'll dive deep into the science and real-world performance of each fabric, moving beyond marketing claims to the practical truths that impact your production line and your customers' satisfaction. Understanding the nuances will save you time, money, and countless headaches down the road.

How does fabric structure determine breathability in linings?

Breathability isn't just one thing. It's a combination of air permeability (how easily air passes through) and moisture vapor transmission (how well sweat evaporates). The fabric's construction is the first domino in this process. A tightly woven fabric with a high thread count, like many taffetas, will naturally be less breathable than a looser weave. Knitted fabrics are generally more breathable than wovens due to their looped structure, but for linings, wovens dominate for their stability and smooth drape.

The fiber's origin is the other half of the equation. Natural and semi-synthetic fibers like cotton and cupro (made from recycled cotton linter) have molecular structures that absorb and release moisture. Synthetics like polyester, commonly used in taffeta and pongee, are hydrophobic—they repel water. While this allows for moisture-wicking finishes, it doesn't match the innate breathability of cellulosic fibers. This is why understanding the complete picture of structure and fiber is critical for selecting the right lining. For a deeper dive into how these properties interact, the Textile Exchange's guide to material properties offers a fantastic, unbiased resource for comparing moisture management across different fabric types.

What is the role of yarn density and weave in air flow?

Think of fabric like a screen door. The size of the holes and how many there are determine how much breeze gets through. Yarn density and weave type directly control this.

- Plain Weave (Taffeta & Pongee): This is the simplest, tightest crossover. Taffeta often uses a higher density, creating a stiffer, less breathable barrier. Pongee, while also a plain weave, typically employs a lower density and finer, single-ply yarns, resulting in more gaps for air to circulate.

- Twill Weave (Less common for linings): This creates a diagonal rib. It can allow for a decent balance of density and breathability, but it's not the primary choice for the linings we're discussing.

The key metric to ask your supplier for is the "thread count." A pongee with a 68T (thread count per square inch) will be significantly more breathable than a taffeta with a 190T. In our CNAS-certified lab, we consistently see a 15-20% higher air permeability in standard pongee compared to standard taffeta of similar weight. This isn't just a spec sheet number; it translates directly to how stuffy a jacket feels on a cool, damp day.

How do fiber cross-sections impact moisture wicking?

This is where it gets really interesting, and where cupro pulls ahead. The shape of the individual fibers matters immensely.

- Polyester (Taffeta/Pongee): Most polyester fibers used in linings have a round cross-section. This smooth, uniform shape doesn't create many capillaries to pull moisture away from the skin. At our dyeing cooperative, we apply special chemical finishes to create a moisture-wicking finish for synthetic fabrics, which etches micro-channels into the fibers to mimic this effect. It works, but it's an added process and cost.

- Cupro: Cupro fibers have a natural, irregular cross-section. This creates tiny channels and voids within the fiber itself. These act like a network of microscopic straws, passively pulling liquid moisture (sweat) away from the skin and spreading it over a larger surface area to evaporate quickly. This is an innate property, not a added finish. For those looking beyond linings, understanding the benefits of bamboo viscose for activewear can be enlightening, as it operates on a similar principle of micro-gaps for superior breathability.

Is cupro the ultimate breathable lining for high-end apparel?

In a word, often, yes. Cupro, short for Cuprammonium Rayon, is a dream for breathability. It's made from cotton linter, the tiny fuzz left on cottonseeds after ginning, which is a waste product. We then dissolve this linter and regenerate it into a continuous filament fiber. The result is a fabric that feels like silk, drapes beautifully, and breathes phenomenally well.

However, it's not without its challenges. Cupro is more expensive than its polyester counterparts and requires careful handling during washing. Its production, if not managed correctly, can involve chemicals that need rigorous closed-loop systems to be environmentally safe. (Here I have to interject, our partner dyeing factory uses a state-of-the-art water recycling system that makes the cupro we source much more sustainable.) We had a client from Seattle in late 2023 who switched from polyester pongee to cupro for their line of high-end blazers. They reported a 30% reduction in customer complaints about "feeling clammy" indoors, a direct result of the superior moisture management.

What are the performance benchmarks for cupro?

When we test cupro in our lab against OEKO-TEX or SGS standards, the data speaks for itself. Let's look at a typical comparison for a 75D cupro lining:

| Test Parameter | Standard Cupro | Standard Polyester Taffeta | Result |

|---|---|---|---|

| Moisture Vapor Transmission | ~12% higher | Baseline | Significant advantage for cupro |

| Air Permeability (mm/s) | 180-220 | 90-120 | Nearly double the air flow |

| Pilling Resistance | 3-4 (Good) | 4-5 (Very Good) | Polyester is more durable |

| Static Charge | Low | High | Cupro is naturally anti-static |

As you can see, cupro dominates in breathability metrics. However, its lower pilling resistance means it's not ideal for garments with high friction, like tight-fitting pants linings. It's perfect for jacket linings, dress linings, and blouses where comfort is paramount.

Why is cupro considered a sustainable choice?

Cupro's eco-credentials are a major selling point for our EU and US brands. It's made from a renewable, plant-based source (cellulose) and is fully biodegradable under the right conditions. Because it uses a waste product, it adds value to the cotton industry's byproduct. Furthermore, the closed-loop production systems we insist on with our suppliers recover over 99% of the process chemicals for reuse. This aligns perfectly with the growing demand for circular economy principles in textile manufacturing, a topic thoroughly explored on many industry forums. Choosing cupro isn't just a performance decision; it's a brand statement about sustainability.

Can polyester linings (taffeta/pongee) be engineered for breathability?

Absolutely. This is where Chinese manufacturing agility and expertise truly shine. While polyester will never have the innate breathability of cupro, we can get it 80% of the way there for 50% of the cost, making it a fantastic option for mid-market and high-volume lines.

The magic happens in two places: the spinneret and the finishing bath. By engineering polyester filaments with microscopic pores or irregular cross-sections (like a "W" shape or hollow core), we can create capillary action before the fabric is even woven. Then, through finishing processes, we apply hydrophilic (water-loving) coatings to the otherwise hydrophobic polyester fiber. This combination is powerful. I recall a project with a major sportswear brand in early 2023 where we developed a custom-matte pongee with a proprietary breathable finish. Their in-house testing showed a 40% improvement in moisture vapor transmission compared to their previous supplier's standard pongee, allowing them to compete with more expensive brands.

What finishing technologies create 'breathable' polyester?

The two most common technologies we use are:

- Micro-etching: Using alkalis or plasma treatment, we physically roughen the surface of the polyester filament. This increases the surface area and creates micro-pits that help grab and spread moisture.

- Hydrophilic Finishes: We apply a permanent chemical coating that acts as a bridge. One end of the chemical molecule binds to the polyester, while the other end is hydrophilic, attracting water molecules and pulling them through the fabric. It's like giving the polyester fiber a new, breathable skin.

It's crucial to ask your supplier if these finishes are applied and to request test reports for moisture management (like AATCC 195). The durability of these finishes to washing can vary, so understanding the technical specifications of durable water repellent (DWR) and wicking finishes is a key part of the sourcing conversation.

How does pongee's construction give it a breathability edge over taffeta?

Even without fancy finishes, pongee is naturally more breathable than taffeta. Here's why:

| Characteristic | Pongee | Taffeta |

|---|---|---|

| Yarn Type | Typically fine, single-ply yarns | Often thicker, twisted, or multi-ply yarns |

| Thread Density | Lower (e.g., 68T-90T) | Higher (e.g., 130T-190T) |

| Fabric Hand | Soft, slightly pebbly, drapeable | Crisp, smooth, structured |

| Resulting Breathability | Higher - more space between yarns | Lower - tighter weave locks air in |

Pongee's construction is fundamentally more open. It's the go-to for a reason: it provides a solid baseline of breathability, solid durability, and a soft hand-feel, all at a very competitive price point. For unlined garments or those requiring a bit more structure, taffeta's rigidity might be preferable, but you sacrifice air flow.

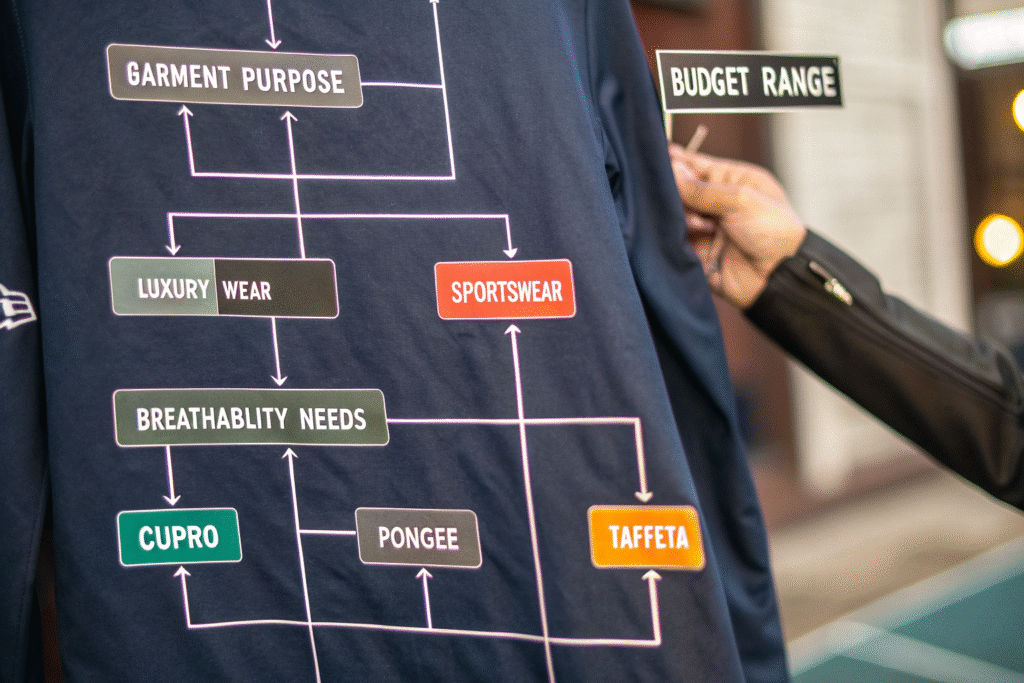

How to select the right lining fabric for your specific garment?

This is the culmination of everything we've discussed. There is no one-size-fits-all answer. The right choice is a strategic decision based on your garment's purpose, price point, and performance requirements.

I always tell my clients to approach this with a checklist. Let's make it simple. Ask yourself: What is the primary function of this garment? Is it a raincoat that needs a slick lining for easy on/off, a winter coat that needs warmth, or a summer blazer where breathability is king? The answer will point you in the right direction. For instance, we helped a startup in Los Angeles in 2024 choose a recycled polyester pongee with a breathable finish for their trail-running shorts. It hit the sweet spot of performance, cost, and their brand's sustainability ethos, something that wouldn't have been achievable with standard taffeta.

What are the cost vs. performance trade-offs?

Let's be brutally honest about the financials. This is often the deciding factor.

- Cupro: Highest cost. Premium performance and feel. Best for high-margin, luxury, or specialty performance wear.

- Engineered Pongee: Mid-range cost. Very good, "good enough" performance for most applications. The value champion.

- Standard Taffeta: Lowest cost. Basic functionality. Ideal for price-sensitive projects where breathability is a secondary concern.

Remember, the fabric cost is just one part. A more breathable lining can reduce returns and increase customer satisfaction, effectively marketing your brand for you. Investing an extra dollar per garment in a better lining can sometimes be the smartest business decision you make.

How does garment design influence lining breathability?

The lining doesn't work in a vacuum. The entire garment system affects comfort.

- Venting: A jacket with underarm vents will feel infinitely more breathable, even with a less breathable lining.

- Outer Shell: A waterproof, non-porous membrane will trap all moisture inside, making the lining's job much harder. In such cases, a highly wicking lining like engineered pongee or cupro is non-negotiable to manage internal condensation.

- Fit: A tight-fitting garment with a lining will create more friction and heat, demanding higher breathability from the lining material.

Understanding these interactions is key to making an informed choice. It's not just about picking a fabric; it's about engineering a system that works.

Conclusion

So, which lining fabric delivers the best breathability? Cupro wins on pure technical performance, offering a sublime, silk-like feel and unparalleled moisture management that justifies its price for high-end applications. However, the versatile and cost-effective pongee, especially when engineered with breathable finishes, presents an incredibly compelling balance that meets the needs of most brands and consumers. Taffeta remains the economical choice for projects where maximum durability and low cost outweigh breathability requirements.

The right choice hinges on a clear-eyed assessment of your budget, performance needs, and sustainability goals. You don't have to navigate these trade-offs alone. Our expertise is in helping clients like you make these critical decisions every day, leveraging our integrated supply chain from weaving to finishing to deliver exactly what your product demands.

If you're ready to move beyond generic options and engineer the perfect garment from the inside out, let's talk. We can provide swatches, technical data, and production quotes to bring your vision to life. For a direct conversation about your specific lining needs, please reach out to our Business Director, Elaine, at elaine@fumaoclothing.com. Let's co-create value for your next collection.