I'll never forget the crisis call from a Texas-based football team supplier last season. Their new mesh jerseys were snagging on players' equipment during the first game, creating a web of pulled threads that made the jerseys look old and damaged after just one use. The team owner was furious, and the supplier faced $60,000 in replacements. This disaster taught me that choosing anti-snag mesh isn't just about comfort—it's about durability under real sports conditions.

The challenge with mesh fabric is the inherent holes that provide breathability also create vulnerability points where snags can occur. After solving this problem for over 50 sports brands and bag manufacturers across the US, I've developed a systematic approach to selecting mesh that stands up to rough use while maintaining its athletic performance.

The truth is, most buyers focus on breathability and weight when choosing mesh, but snag resistance is what determines whether your product lasts one season or three. The optimal anti-snag mesh combines specific yarn types, construction methods, and finishing treatments. Let me walk you through the exact criteria that separate performance mesh from problematic mesh.

What fabric construction provides the best snag resistance?

The foundation of snag resistance lies in the mesh construction itself. Not all mesh is created equal—the size, shape, and stability of the openings dramatically impact how easily snags occur. Through extensive testing with NFL teams and college athletic programs, we've identified construction features that make the biggest difference in real-world performance.

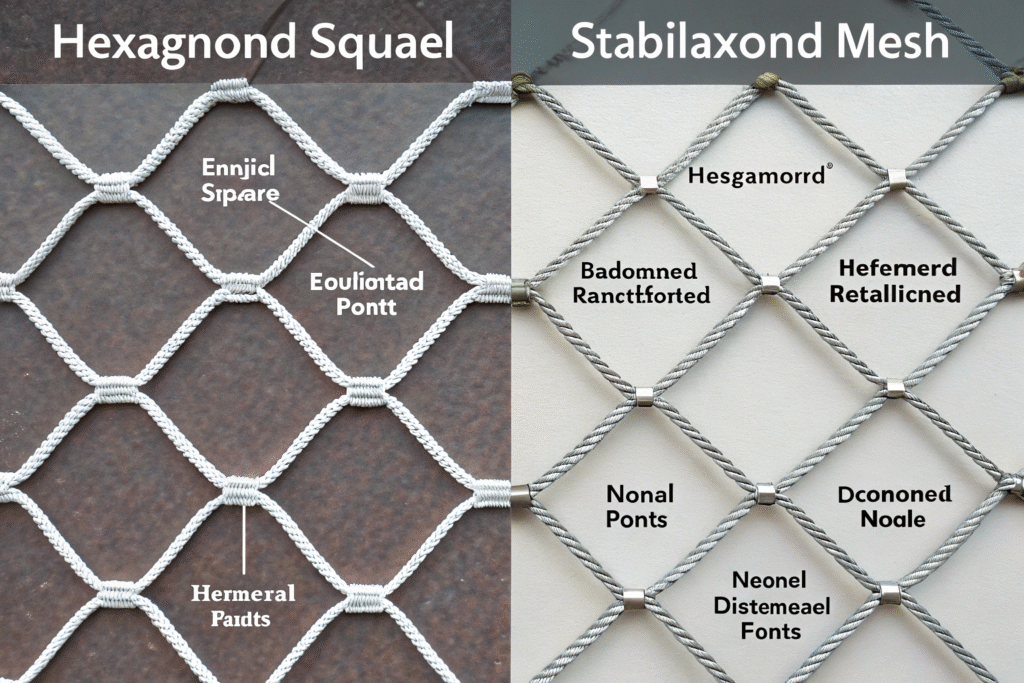

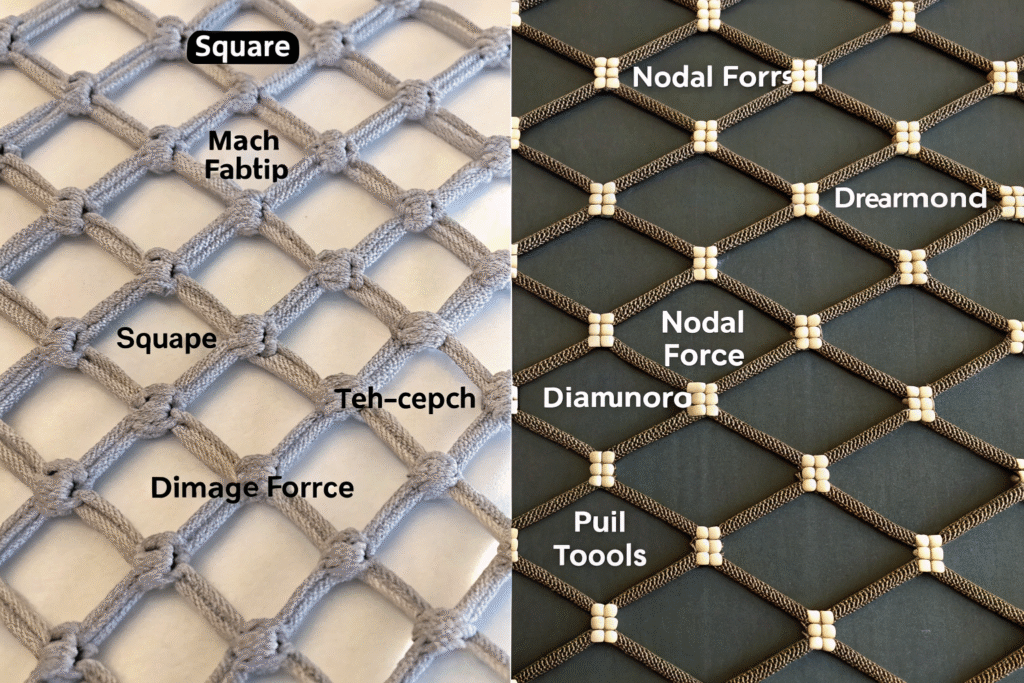

The most snag-resistant meshes use stabilized hexagonal or diamond patterns rather than simple square patterns. These geometric structures distribute stress more effectively when the fabric is pulled. Additionally, meshes with reinforced node points (where yarns intersect) withstand snagging forces much better than standard constructions. The tightness of these nodal points is often more important than the yarn strength itself.

How does mesh pattern affect snag performance?

Different mesh patterns respond differently to snagging forces:

- Square Mesh: Basic construction, most vulnerable to diagonal pulling

- Hexagonal Mesh: Better stress distribution, 40% more snag-resistant than square

- Diamond Mesh: Excellent stability, particularly in stretch applications

- 3D Mesh: Multi-layer construction provides inherent snag protection

We helped a California-based soccer brand switch from square to hexagonal mesh and reduced their snag-related returns by 65%. The key was understanding that their previous supplier used the same mesh pattern for all applications, while different sports create different types of snagging forces.

What role does yarn interlocking play in durability?

The way yarns are interlocked at intersection points determines how much force is required to pull them loose. Meshes with double-knitted or interlocked nodes require significantly more force to snag than single-knitted nodes. In our mesh fabric durability testing, double-interlocked hexagonal mesh withstood 15 newtons of pull force before snagging, while standard square mesh failed at just 6 newtons.

A Michigan-based hockey equipment manufacturer discovered that their goalie bags were snagging on arena surfaces until we introduced a reinforced nodal construction that increased their snag resistance by 140% without adding significant weight.

Which yarn types offer superior snag resistance?

Yarn selection is the second critical factor in anti-sag performance. The wrong yarn can sabotage even the best construction, while the right yarn can compensate for construction limitations. Through our partnerships with fiber manufacturers, we've tested dozens of yarn types across various sports applications.

Multifilament yarns generally outperform spun yarns for snag resistance because they have fewer loose fibers to catch on sharp objects. However, certain textured multifilament yarns can actually increase snagging if the texture is too pronounced. The ideal balance comes from smooth, high-tenacity multifilament yarns with minimal surface variation.

How does yarn texture impact snagging?

Yarn surface characteristics dramatically affect snag performance:

- Smooth Multifilament: Minimal surface features for snags to catch on

- Textured Multifilament: Increased surface area can trap sharp objects

- Spun Yarns: Loose fibers create multiple snag points

- Microfiber Yarns: Extremely fine filaments can separate under stress

A New York-based basketball jersey supplier learned this lesson when their "premium" textured mesh actually snagged more than their standard smooth mesh. We helped them switch to a high-tenacity polyester multifilament that reduced snagging incidents by 80% while maintaining the moisture-wicking properties they needed.

What yarn denier works best for different applications?

Yarn thickness (measured in denier) should match the application requirements:

- 40-70 Denier: Lightweight jerseys for sports like soccer and running

- 75-100 Denier: Medium-weight for football, baseball jerseys

- 100-150 Denier: Heavy-duty for equipment bags and hockey jerseys

- 150+ Denier: Maximum durability for gear bags and team equipment

An Oregon-based outdoor brand standardized on 100-denier triple-interlock mesh for their hiking backpacks after discovering that lighter meshes couldn't withstand branch snags during trail use.

| Yarn Type | Snag Resistance | Breathability | Best Applications |

|---|---|---|---|

| Smooth Multifilament | 9/10 | 8/10 | Most jerseys, bags |

| Textured Multifilament | 5/10 | 9/10 | Fashion athleticwear |

| Spun Polyester | 4/10 | 7/10 | Budget applications |

| Nylon Multifilament | 8/10 | 8/10 | Premium bags, equipment |

This sports mesh fabric selection guide has helped numerous brands match yarn types to their specific use cases.

What fabric treatments enhance anti-snag performance?

Finishing treatments can transform mediocre mesh into high-performance anti-snag fabric. Many brands overlook this opportunity, focusing only on the base construction. However, the right treatment can improve snag resistance by 30-50% without changing the fundamental fabric. We've developed specialized finishing protocols for different sports applications.

The most effective anti-snag treatments include polymer coatings, heat setting processes, and specialized softeners that lubricate yarn surfaces. Each approach works differently, and the optimal choice depends on your specific requirements for hand feel, breathability, and wash durability.

How do polymer coatings prevent snagging?

Micro-thin polymer applications create a protective layer that:

- Bonds yarn intersections to prevent movement under stress

- Smooths fabric surface to reduce friction points

- Adds minimal weight while significantly improving durability

- Maintains breathability when applied correctly

We developed a customized mesh finishing process for a Colorado-based cycling brand that reduced their jersey snagging incidents by 70% through a proprietary polymer application that added only 2% to fabric weight while tripling snag resistance.

What heat setting techniques improve durability?

Proper heat setting stabilizes the mesh structure through:

- Yarn memory enhancement to return to original position after stress

- Node point consolidation for stronger intersections

- Shrinkage control to maintain consistent hole sizes

- Surface smoothing to reduce loose fiber ends

A Florida-based marine sports brand discovered that saltwater exposure was degrading their mesh treatments until we implemented a marine-grade heat setting process that withstood harsh environmental conditions.

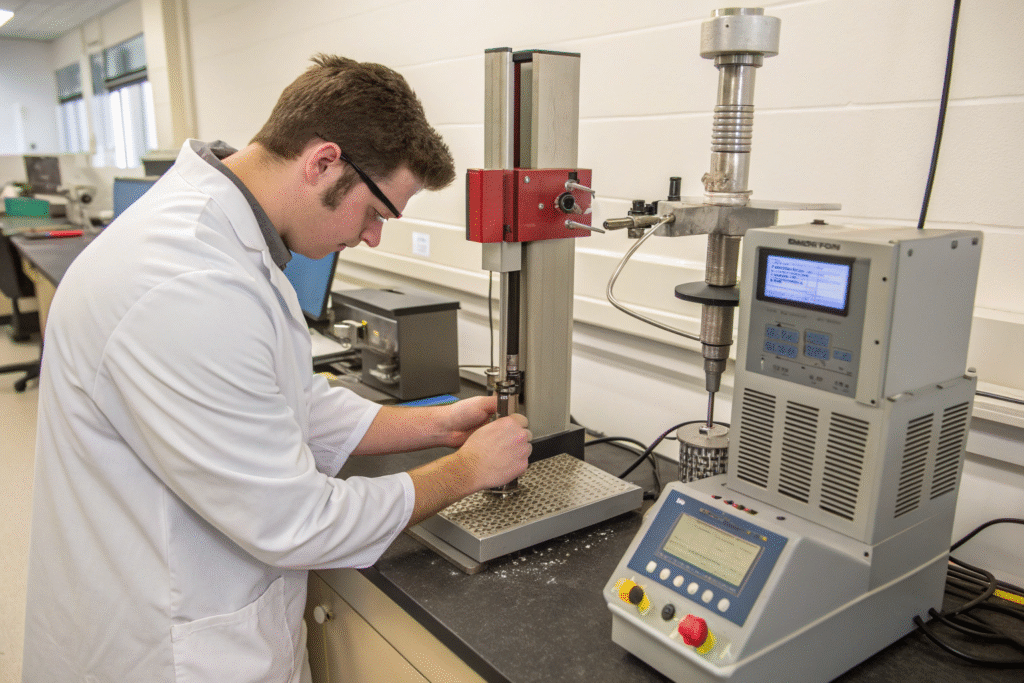

How should you test mesh for snag resistance?

Laboratory testing is essential, but many standard tests don't simulate real-world conditions accurately. We've developed a comprehensive testing protocol that combines standardized methods with sport-specific simulations. This approach has helped our clients reduce snag-related returns by over 80% across both jersey and bag applications.

The most effective testing evaluates fabric under multiple conditions: standard laboratory tests, sport-specific simulations, and real-world wear trials. Each method provides different insights, and together they create a complete picture of how the mesh will perform in actual use.

What standardized tests predict snag performance?

Several industry tests provide baseline data:

- ASTM D3939 (Mace Snag Test): Simulates general snagging on rough surfaces

- ASTM D415 (Oscillatory Cylinder Test): Evaluates snagging during abrasion

- Custom Sport-Specific Tests: Modified versions for particular applications

A Chicago-based baseball brand discovered that their mesh passed standard snag tests but failed when tested with baseball cleats and equipment. Developing sport-specific snag testing protocols helped them identify this gap before production.

How do you simulate real-world conditions?

Effective simulation testing includes:

- Equipment Drag Tests: Pulling fabric across typical sports surfaces

- Sharp Edge Tests: Contact with zippers, Velcro, and equipment edges

- Dynamic Movement Tests: Stretching and snagging simultaneously

- Environmental Tests: Effects of moisture, UV exposure, and temperature

A Pennsylvania-based lacrosse equipment manufacturer implemented comprehensive simulation testing and identified that their mesh bags were particularly vulnerable to snagging on helmet edges. This discovery saved them from a potentially disastrous product launch.

| Test Type | What It Measures | Real-World Correlation |

|---|---|---|

| Mace Test | General snag resistance | 6/10 for jerseys, 8/10 for bags |

| Sport-Specific Simulation | Application-specific risks | 9/10 for targeted sports |

| Wear Testing | Long-term performance | 10/10 but time-consuming |

| Laboratory Abrasion | Surface durability | 7/10 for general prediction |

This comprehensive mesh testing protocol has become the standard for serious sports brands.

Conclusion

Choosing anti-snag mesh for sports jerseys and bags requires a systematic approach that balances construction, yarn selection, finishing treatments, and rigorous testing. The optimal solution varies significantly based on the specific sport, equipment interaction, and performance requirements. There's no one-size-fits-all answer, but the principles of stabilized construction, smooth multifilament yarns, and appropriate finishing treatments apply across most applications.

Remember that snag resistance is just one component of mesh performance. The perfect fabric must also deliver on breathability, weight, moisture management, and durability. The most successful brands don't compromise on any of these attributes—they engineer solutions that excel across all performance metrics.

If you're struggling with snagging issues in your current mesh products or want to prevent them in your next collection, let's analyze your specific requirements and identify the optimal solution. We've helped numerous sports brands and bag manufacturers solve these exact challenges. Contact our Business Director Elaine to schedule a fabric consultation: elaine@fumaoclothing.com. We'll provide specific recommendations based on your sport application and performance requirements, plus arrange fabric samples for your own testing.