To be honest, after twenty years in this business right here in Keqiao, I've noticed something interesting. The same question keeps coming up from our international clients – especially those focused on outerwear. They ask about peached microfiber. Sounds technical, I know. But understanding it? Honestly, it can completely change what you offer in your lightweight jacket line. If you're out there sourcing fabrics that need to balance comfort, style, and pure performance... well, you've definitely landed in the right place.

So, what is it? Personally, I think it's one of the cleverest fabric innovations. Peached microfiber is a synthetic fabric, right? Made from those ultra-fine polyester or polyamide fibers. But the magic is in a special finishing process it goes through. This process—they call it "peaching"—gently works the fabric surface. The result? A soft, fuzzy texture, honestly, just like a peach skin. Is it good for lightweight jackets? Let me be direct: absolutely. Its exceptional softness, its water repellency, its wind resistance, and how ridiculously packable it is... all that makes it a standout choice. You get stylish, functional, comfortable outerwear that, to be honest, appeals to just about everyone.

Let's just peel back the layers on this material, shall we? We're going to explore what makes it so unique. And why it might just be the smartest solution for your very next collection. By the time you're done reading, you'll have a solid grip on its properties, its benefits—and how it really stacks up against the other usual suspects in the jacket world.

What is the peaching process in microfiber, really?

That unique feel—it doesn't just appear. It’s not from the fiber itself, no. It comes from this specific mechanical technique. A lot of buyers, they seek out this fabric for that premium hand-feel. But the engineering behind that luxury? Honestly, few ever really get to see it.

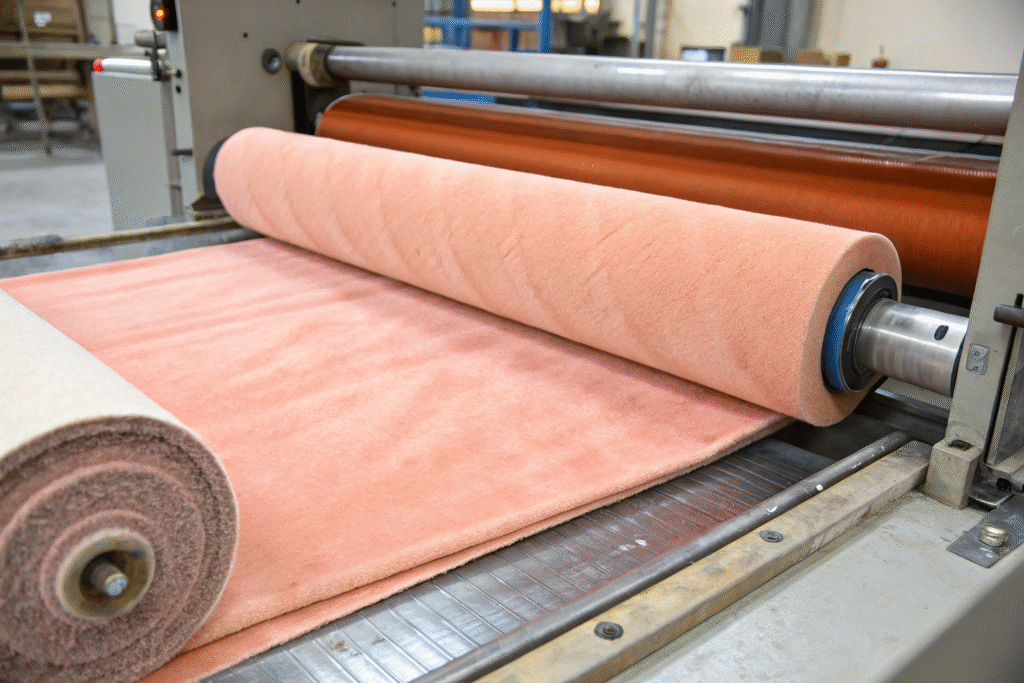

Here’s the thing. The peaching process is a mechanical finish. The fabric gets brushed, see? Brushed with these fine, rotating rollers. That action—it raises the ultra-fine fibers on the surface. Creates a short, dense, uniform nap. The result is that signature texture. Soft, suede-like, peach-skin... incredibly pleasant to touch. It’s different from sanding, you know? Sanding can be more aggressive. This is controlled. A controlled abrasion that just makes the fabric feel better without wrecking its strength. A key value-add, personally I think, for any brand wanting to offer a real tactile experience.

How does peaching actually alter the fabric?

It’s a transformation, a fundamental one. The main change is tactile, no question. It dramatically increases softness, creates this warm, dry hand-feel customers love. But the benefits—they go beyond just touch. Beyond mere touch. The raised nap... it creates countless tiny air pockets. Enhances the fabric's insulation, honestly, without adding any weight. Perfect for those transitional-season jackets. That same structure, it can also improve how the fabric wicks moisture. Now, does the process make the fabric weaker? Not inherently, no. But it is crucial—absolutely crucial—to source from a supplier with rigorous control. At our place, every single batch gets tested. For pilling, for abrasion resistance, all in our CNAS-certified lab. We make sure the finish is beautiful, yes, but also durable. Built to last.

So why is this finish so popular now?

Popularity stems from demand, simple as that. Consumer demand for comfort, for perceived quality. In a market saturated with basic polyester... a peached finish offers a point of difference. A difference your customers can actually feel. This tactile advantage is a powerful tool. A powerful tool at point of sale. It elevates a simple jacket. From a basic item to a desirable piece. Furthermore, the look—the matte, non-shiny appearance—it lends a sophisticated, minimalist aesthetic. Aligns with current trends. Both athleisure and urban fashion. Its versatility? Lets it be used for everything. Sporty anoraks, fashionable bombers. Gives your brand the flexibility to cater to multiple segments. All with one, high-performance fabric.

What are the real benefits for jacket makers?

When you're developing a new line, you need fabrics that deliver. A compelling mix, performance and comfort. Peached microfiber... it hits several key marks. Directly addresses modern consumer needs, to be honest.

The key benefits? Let’s list them. Unparalleled softness. Excellent wind resistance. Reliable water repellency. And lightweight packability. These properties... they make jackets from this material not just comfortable to wear, but highly functional. For everyday use, for travel. The fabric provides a barrier—a superior barrier—against the elements. While still being breathable. Prevents that clammy feel. The clammy feel common in cheaper shells. For you, the buyer, this translates into jackets that are easy to sell. They meet a wide range of expectations. All with a single fabric.

How does it feel for the person wearing it?

Comfort is king. And here, peached microfiber reigns. The peach-skin surface feels warm. Soft against the skin. It eliminates that cold, plasticky feel of standard polyester. Makes the jacket pleasant to put on. Comfortable to wear, even over a simple t-shirt. Then there's the moisture management. The raised nap, the properties of the yarns... they work together. The vast surface area of the fibers wicks perspiration away. More effectively than conventional fabrics, honestly. Keeps the wearer dry. Comfortable during light activity. This combination—thermal and sensorial comfort—ensures the jacket is worn. Not just carried. That increases satisfaction. Makes repeat purchases for your brand far more likely.

What about the performance, the real-world use?

Beyond comfort, it delivers tangible features. Critical for outerwear. First, the dense weave, the brushed surface... they block wind. Effectively. Makes the jacket a great windbreaker. Second, most of these fabrics get a DWR finish. A Durable Water Repellent. Causes water to bead up. Roll right off the surface. Protection against light rain, against drizzle. A third advantage? Packability. The fabric is lightweight. Exceptionally so. Can be compressed into a tiny space. Its own pocket, often. Makes it an ideal travel companion. These traits are highly marketable. Easy to communicate to your customers. They add real value to your product.

How does it really compare? An honest look.

Choosing the right fabric is a comparison. A comparative exercise. Understanding how this one stacks up against alternatives... it helps you decide. An informed decision for your specific line.

| Feature | Peached Microfiber | Nylon Taslan | Standard Polyester | Cotton Twill |

|---|---|---|---|---|

| Weight & Packability | Very Lightweight, Highly Packable | Lightweight, Packable | Lightweight, Packable | Heavy, Bulky |

| Weather Resistance | Good Wind & Light Water Resistance | Excellent Wind & Water Resistance | Fair Wind & Water Resistance | Poor, Absorbs Water |

| Durability | Good | Excellent | Good | Very Good |

| Comfort & Hand-Feel | Exceptionally Soft, Warm Feel | Rough, Technical Feel | Crisp, Can Feel Plastic | Soft, but Stiff when new |

| Care & Wrinkle Resistance | Easy Care, Wrinkle-Resistant | Easy Care, Wrinkle-Resistant | Easy Care, Wrinkle-Resistant | Wrinkles Easily, Shrinks |

Is it more durable, honestly? Than nylon or cotton?

Durability... it depends on the context. For its weight, it's remarkably durable. Those fine fibers are woven tightly. Creates a strong fabric. But heavyweight nylons—like Cordura—will generally offer more. More abrasion resistance for extreme conditions. Now, compared to cotton twill? It’s significantly more resistant. To pilling, to tearing, to mildew. And it doesn’t absorb water. Won't become heavy. Soggy. Won't develop a musty smell like cotton can. Practically speaking, this means jackets keep their new look. Their performance. For longer, with less care. A key selling point, personally I think, for consumers today.

And the cost? The real value?

It sits at a mid-range price, typically. More expensive than standard polyester, sure. But comparable to—sometimes even less than—specialized high-performance nylons. The value, though? Exceptional. You get a fabric that feels more luxurious than it is. More expensive. That perceived value is a powerful advantage for your brand. Lets you position jackets as premium. Without a prohibitive cost. The fabric's versatility also means you can use it across styles. Simplifies your sourcing. Could qualify you for volume discounts. Improves your overall margin structure, to be honest.

Sourcing this fabric? What you must consider.

Sourcing this material... it goes beyond just finding a supplier. A supplier who has it. To ensure quality—real consistency for your brand—you need to dig deeper. Into the specifics of the material, and the supplier's capabilities. Their real capabilities.

The most critical factors? The fabric's density—the GSM. The quality of the DWR finish. The colorfastness of that peached surface. You must partner with a supplier that provides transparency. Reliable test reports for these things. Furthermore, consider their ability to support your speed. Your development speed. And their experience... in handling logistics. The complexities of international shipping. Especially with things like US tariffs, which are always evolving.

What technical specs are non-negotiable?

Two are most important. GSM and hydrostatic head rating. The GSM indicates weight. And indirectly, density, durability. For lightweight jackets, 80-120 GSM is typical. The sweet spot. A balance of substance and packability. The hydrostatic head rating—often with a spray test—quantifies water resistance. 1000-3000mm is suitable. Suitable for weather-resistant urban jackets. Always, always ask for verification. From an international service like SGS. At Fumao, we provide QR codes. They link directly to the test reports. Gives you and your customers full confidence. Confidence in the performance claims.

How to ensure consistency? And timely delivery?

Consistency is the hallmark. The hallmark of a professional. The peaching process must be calibrated. Monitored. To ensure every meter has the same sublime hand-feel. Ask potential suppliers about their in-process control. Ask if they have a CNAS-certified lab for internal testing. For delivery, understand their lead times. Their logistics partnerships. Our integrated supply chain here in Keqiao, for example, allows for 48-hour sampling. Quick bulk delivery. We also have strategies to ship directly to the US. Avoiding tariff impacts. Provides a cost advantage—a significant one—and predictability. For American buyers like Ron. Choosing a supplier with a robust operation... it's as important as the fabric spec itself.

Conclusion

So, peached microfiber stands out. A top-tier choice for lightweight jackets. It blends a luxurious hand-feel with practical, everyday performance. Masterfully. Its resistance to wind and rain—light rain—coupled with its packability and comfort... makes it versatile. Highly marketable. However you compare it—to polyester, nylon, or cotton—it holds its own. Offers a unique combination. Attributes that consumers actively seek today. Understanding the process, the benefits, the sourcing details... it empowers you. To make informed decisions. Decisions that will truly elevate your product line.

If you're looking to develop your own line... high-quality, comfortable, stylish jackets with this material... we should talk. Our team specializes in guiding brands. Through the entire process. From fabric selection to final production. For a direct conversation—about your specific needs—please reach out. To our Business Director, Elaine. She can provide tailored solutions. Samples, too. Her email is: elaine@fumaoclothing.com.