If you appreciate quality clothing or work in the fashion industry, you've probably heard about selvedge denim. It's known for being premium and durable, but what makes it different from regular denim, and is it really worth the higher cost? As an experienced textile manufacturer from China's main fabric district, I'll explain the real benefits of this special denim. We work with clients worldwide who care about both quality and smart spending.

Yes, selvedge denim is more durable than regular denim because of how it's made. The secret is in the old-style looms used to weave it. These looms create a finished edge that doesn't fray and produce a tighter, stronger fabric. But the full story includes the quality of cotton used and the dyeing methods. Together, these elements create denim that can last for many years while developing a unique look with wear.

Let's explore what makes selvedge denim special. We'll look at how it's made, why it's stronger, how it compares to other denim, and how to find good quality selvedge for your needs.

What Makes Selvedge Denim Different?

Selvedge denim is recognized by its neat, finished edges that don't unravel. The word "selvedge" comes from "self-edge," which describes this special finished edge. This edge is created using traditional shuttles that weave fabric more slowly than modern machines. The continuous weaving process creates a tight, closed edge that's both practical and attractive. The colored thread often seen in this edge is a signature detail that shows quality craftsmanship.

The way selvedge denim is woven makes it special. While most denim today is made on fast, wide machines, selvedge uses slower, traditional methods. This slower process creates a denser, more substantial fabric that many consider higher quality. This traditional approach appeals to those who appreciate craftsmanship and lasting quality in their clothing.

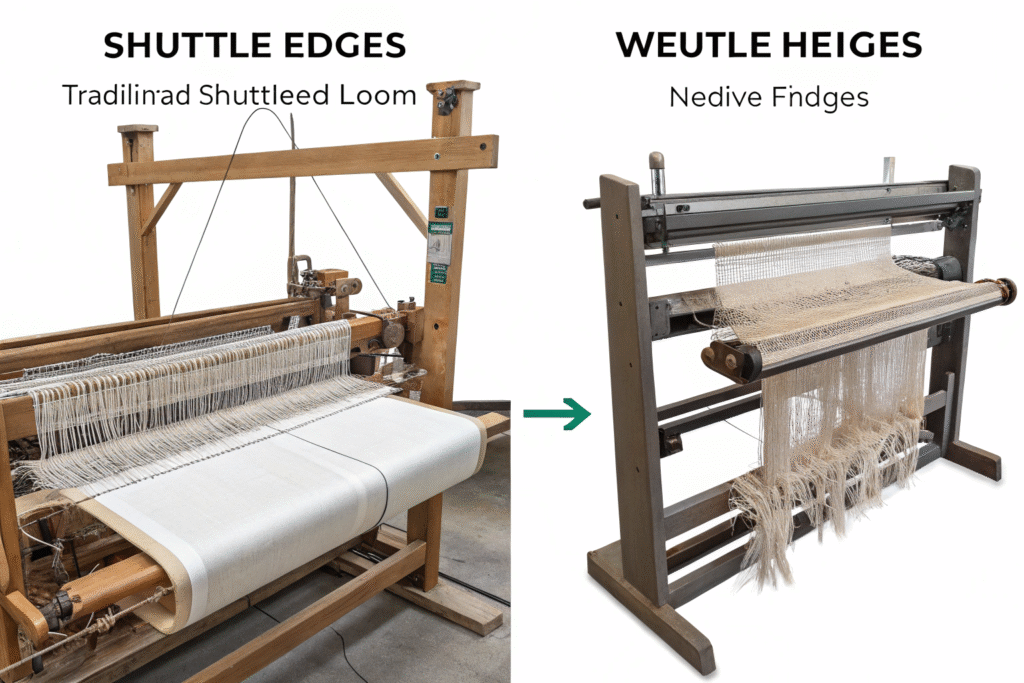

How is the Weaving Process Different?

The main difference is in the equipment. Traditional shuttle looms weave fabric by moving the cross-threads back and forth continuously. This creates finished edges on both sides of the fabric. While this method is slower and produces narrower fabric, it results in stronger edges that don't fray. Most regular denim is made on high-speed machines that create unfinished edges. These edges must be sewn or finished later to prevent fraying, which can weaken over time.

What's the Significance of the Colored Edge?

The colored thread in the edge, usually red but sometimes other colors, originally helped identify which factory made the fabric. While it still serves this purpose for experts, it has become a mark of quality and attention to detail. For buyers and consumers, it's a visual sign that they're getting genuine selvedge denim made with care.

Why Does Selvedge Denim Last Longer?

The durability of selvedge denim comes from several factors working together. First, the tight weave from the traditional looms creates a dense fabric that resists wear and tear. Think of it like a tightly woven basket versus a loosely woven one - the tight one is naturally stronger. Second, selvedge denim often uses better quality cotton with longer fibers. These longer fibers create stronger threads that are less likely to break or pill over time.

The dyeing process also contributes to durability. Rope dyeing, commonly used for selvedge, involves dipping the threads multiple times in indigo before weaving. This allows the color to penetrate deeper into the fibers compared to faster dyeing methods. Deeper dye penetration means the cotton fibers are better protected, and the color fades more gradually rather than wearing off quickly. This careful attention to every production step is what makes selvedge denim so long-lasting.

How Does Tight Weaving Increase Strength?

The closeness of the weave directly affects how strong the fabric is. Selvedge denim typically has more threads per inch woven more tightly together than regular denim.

| Fabric Type | Weave Tightness | Durability Impact |

|---|---|---|

| Selvedge Denim | Very Tight | Resists wear and tearing well |

| Regular Denim | Medium to Loose | Wears out more quickly |

Tight weaving means the threads support each other better, spreading any stress across the fabric instead of letting it concentrate in one area. This makes the fabric less likely to develop weak spots or tears.

Does Cotton Quality Matter for Longevity?

Absolutely. The length of cotton fibers makes a big difference in how strong the final fabric will be. Longer fibers, like those in premium cotton types, can be spun into smoother, stronger threads. When these strong threads are woven tightly using selvedge methods, the result is exceptionally durable fabric. Shorter cotton fibers, often used in mass-produced denim, create weaker threads that are more likely to pill, break, or wear thin in areas of stress.

Selvedge and Shrinkage: What Should You Know?

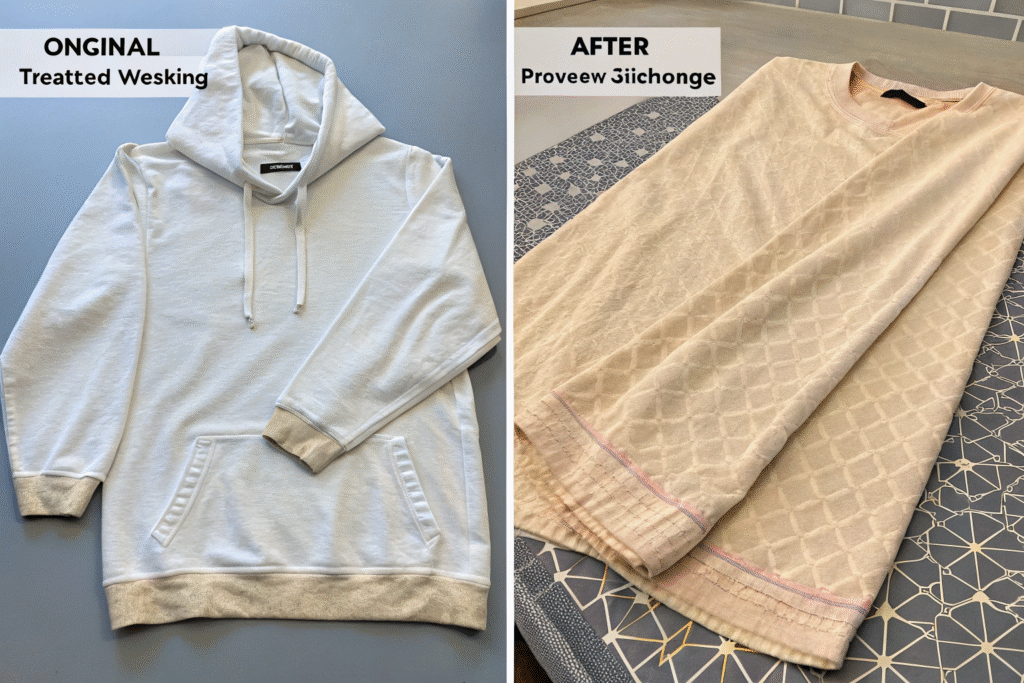

It's important to understand that selvedge refers to the edge finish, while shrinkage control is a separate process. Most selvedge denim available today has been treated to minimize shrinkage. The shrink-resistant treatment involves stretching and heating the fabric to remove most of its natural shrinkage, usually limiting it to 1-3%. This makes the fabric predictable for clothing manufacturers and consumers alike.

Some selvedge denim is sold without this treatment, meant to shrink to fit the wearer's body after the first wash. While this can create a perfect custom fit, it requires careful handling and knowledge. For most clothing brands and consumers, shrink-treated selvedge denim offers the best combination of traditional quality and modern convenience.

What are the Benefits of Shrink-Treated Denim?

Advantages:

- Consistent Sizing: Clothes keep their size after washing

- Easier Manufacturing: Simplifies pattern making and production

- User-Friendly: No special washing instructions needed

Considerations:

- Different Fading Pattern: May fade differently than untreated denim

- Less Traditional: Some experts prefer completely natural denim

When Should You Choose Untreated Selvedge?

Choose untreated selvedge only if you're experienced with premium denim and understand the shrinking process. It works best for custom clothing or limited editions where the unique fit and fading process are valued. For everyday wear or commercial clothing lines, shrink-treated selvedge is usually the better choice.

How to Find Quality Selvedge Denim Manufacturers?

Finding reliable selvedge denim suppliers requires careful research. Look for manufacturers who are transparent about their production methods and quality standards. Ask potential suppliers about their quality checking processes - how they ensure consistent weaving, even coloring, and proper edge finishing. Good suppliers will have thorough inspection systems at each production stage.

Also check what kind of quality verification they provide. Reputable manufacturers can supply test results for important qualities like shrinkage, color fastness, and fabric strength. These objective measurements help guarantee the denim will perform as expected. Finally, consider the supplier's experience with international shipping and understanding of requirements for different markets.

What Should You Check for Quality?

When evaluating selvedge denim quality, focus on these aspects:

- Edge Quality: The finished edge should be straight and consistent with clean, colored threads

- Weave Consistency: The fabric surface should have even texture without thin spots or flaws

- Color Evenness: The indigo dye should be consistent across the fabric

How to Verify Manufacturer Quality Claims?

Ask for independent test reports from recognized testing organizations. These reports provide objective data about fabric performance. Also request fabric samples to examine personally. A trustworthy manufacturer will be happy to provide samples and answer detailed questions about their production methods and quality standards.

Conclusion

Selvedge denim offers genuine durability advantages through its traditional weaving methods, tight construction, and often superior materials. The finished edge is both a quality mark and a functional benefit. While it costs more than regular denim, the investment makes sense for those who value long-lasting quality and unique character that develops over time.

If you're interested in working with selvedge denim for your clothing line, we'd be happy to help. Our company specializes in producing quality selvedge denim with complete quality control from weaving to finishing. We understand the needs of international markets and can help you navigate fabric selection and shipping logistics. For more information, please contact our Business Director, Elaine, at elaine@fumaoclothing.com.