As a fabric manufacturer with over two decades in the textile hub of Keqiao, I often hear clients ask about dyeing methods. The choice between fiber-dyed, top-dyed, and solution-dyed fabrics can be confusing. Yet, it is one of the most critical decisions affecting your fabric's colorfastness, cost, and environmental impact. Understanding these methods helps you source the right material for your fashion line, sportswear, or home textiles. It ensures you meet quality standards and satisfy your customers' demands for durable, vibrant colors.

Fiber-dyed, top-dyed, and solution-dyed are three distinct methods of adding color to textiles at different stages of production. Fiber-dyeing colors the raw fibers before spinning, offering superior color penetration and rich, deep shades. Top-dyeing is similar but applies to wool fibers after they are combed into a sliver. Solution-dyeing, also known as dope-dyeing, incorporates pigments directly into the synthetic polymer before it is extruded into a fiber, resulting in exceptional colorfastness and UV resistance. Each method has unique advantages for color longevity, production speed, cost, and environmental footprint, making them suitable for different applications in the textile industry.

Choosing the right dyeing technique is essential for your product's success. It influences everything from lead times to color consistency across large orders. Let's break down these three methods so you can make an informed decision for your next fabric purchase.

What is fiber-dyed fabric?

Fiber-dyed fabric begins with coloring the raw, loose fibers. Think of cotton, wool, or silk in their natural state before they are spun into yarn. This method is one of the oldest and most revered for achieving deep, lasting colors. The dye penetrates the entire fiber core, resulting in exceptional colorfastness. This means the color is less likely to fade from washing or sunlight. For brands focused on heirloom quality or rich, saturated hues, fiber-dyeing is often the gold standard.

The process involves immersing the loose fibers into large dye baths. After dyeing, the colored fibers are spun into yarn and then woven or knitted into fabric. A key advantage is the ability to create heathered or melange effects by blending different colored fibers before spinning. This method is common for high-quality cotton shirts and luxurious wool suiting. However, it requires significant water, energy, and time. It is also less flexible for small orders, as the minimum dyeing quantity is usually large.

Why choose fiber-dyed fabric for color richness?

The number one reason to choose fiber-dyed fabric is its unparalleled color richness and depth. Because the dye permeates the entire fiber, the color is integral to the material. It does not just sit on the surface. This leads to a vibrant, long-lasting hue that maintains its integrity even with abrasion. For products where color is a critical selling point, such as luxury fashion essentials or high-end upholstery, this depth of color is a major value-add. The fabric has a rich, sophisticated look that is hard to replicate with other methods.

How does fiber-dyeing impact production lead times?

Fiber-dyeing significantly impacts production lead times, usually extending them. The process adds multiple steps before spinning can even begin. Sourcing raw fibers, dyeing them, and then drying them takes considerable time. Furthermore, color matching and achieving consistency across different dye batches can be complex. While our agile supply chain in Keqiao helps streamline this, you should plan for a longer timeline compared to piece-dyeing. This method is best for large, planned orders rather than last-minute, fast-fashion needs.

What is top-dyed fabric?

Top-dyed fabric is a specific term used primarily in the wool industry. "Top" refers to the long, combed wool fibers that have been aligned and formed into a loose rope or sliver. Top-dyeing involves coloring this sliver after the combing process but before it is spun into yarn. It shares many benefits with fiber-dyeing, such as excellent color penetration and the ability to create blended colors. This method is essential for producing high-quality, uniform-colored woolen fabrics like those used in fine sweaters and suiting.

The top-dyeing process ensures the color is locked into the wool fibers, leading to superior colorfastness. It allows for precise color consistency across large production runs, which is crucial for major brands. A key advantage is the efficiency in producing melange yarns. Different colored tops can be blended in specific ratios to achieve a vast spectrum of heathered shades without holding massive inventories of every possible color. This supports our capability for small-batch customization even for complex colors.

Is top-dyed fabric better for wool blends?

Yes, top-dyed fabric is particularly advantageous for wool blends. While the "top" itself is often 100% wool, the dyed top can be blended with other fibers like polyester or acrylic during the spinning stage. This allows manufacturers to combine the luxurious feel and color depth of dyed wool with the durability, cost-effectiveness, or functional properties of synthetic fibers. The result is a high-performance blend that maintains a rich, heathered appearance, ideal for athleisure and outdoor wear that demands both aesthetics and function.

What are the cost implications of top-dyeing?

The cost implications of top-dyeing are generally on the higher end. The process itself is resource-intensive, requiring specialized equipment and skilled labor. The raw material—high-quality combed wool top—is also more expensive than raw wool. However, it can be cost-effective for larger orders by ensuring impeccable color consistency and reducing the risk of shade variation between batches. This minimizes costly rejections. For businesses targeting the premium market, the investment in top-dyed fabrics pays off through a superior final product that justifies a higher price point.

What is solution-dyed fabric?

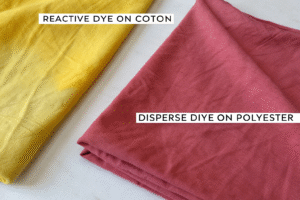

Solution-dyed fabric is a modern, innovative dyeing method used for synthetic fibers like polyester, nylon, and acrylic. The color is added at the very beginning of the fiber-making process. Pigments are infused directly into the liquid chemical solution (the "dope") before it is forced through a spinneret to create solid-colored filaments. This integrates the color at a molecular level, making it an intrinsic part of the fiber itself. This method is revolutionizing industries that demand extreme colorfastness and durability.

The benefits of solution-dyeing are profound. It offers exceptional resistance to fading from UV light, chlorine, and repeated washing. The process is also incredibly eco-friendly, as it uses significantly less water and energy compared to traditional dyeing. There are no wastewater issues associated with dye baths. At Fumao, we use this method for our eco-friendly innovations and high-performance fabrics, including those for outdoor furniture, awnings, and sportswear. It ensures vibrant colors that last for years, even in harsh conditions.

Why is solution-dyed fabric more UV resistant?

Solution-dyed fabric is inherently more UV resistant because the pigments are embedded throughout the entire fiber, not just applied to the surface. When UV rays hit the fabric, they have to penetrate through this solid, continuous color layer. This makes it extremely difficult for sunlight to break down the color molecules. In contrast, the surface dyes on conventionally dyed fabrics are more directly exposed and vulnerable to fading. This makes solution-dyed materials the best choice for outdoor wear and home textiles like curtains and cushions that receive constant sun exposure.

How does solution-dyeing support sustainable fashion?

Solution-dyeing is a cornerstone of sustainable fashion. Its environmental benefits are substantial. The process can reduce water consumption by up to 90% and cut energy use and carbon emissions by nearly 50% compared to traditional dyeing. It completely eliminates the toxic dye effluent that pollutes waterways. By using solution-dyed recycled polyester (rPET), we double down on sustainability, creating fabrics with a minimal environmental footprint. This aligns perfectly with global trends and certifications like OEKO-TEX, helping brands meet their sustainability goals and appeal to eco-conscious consumers.

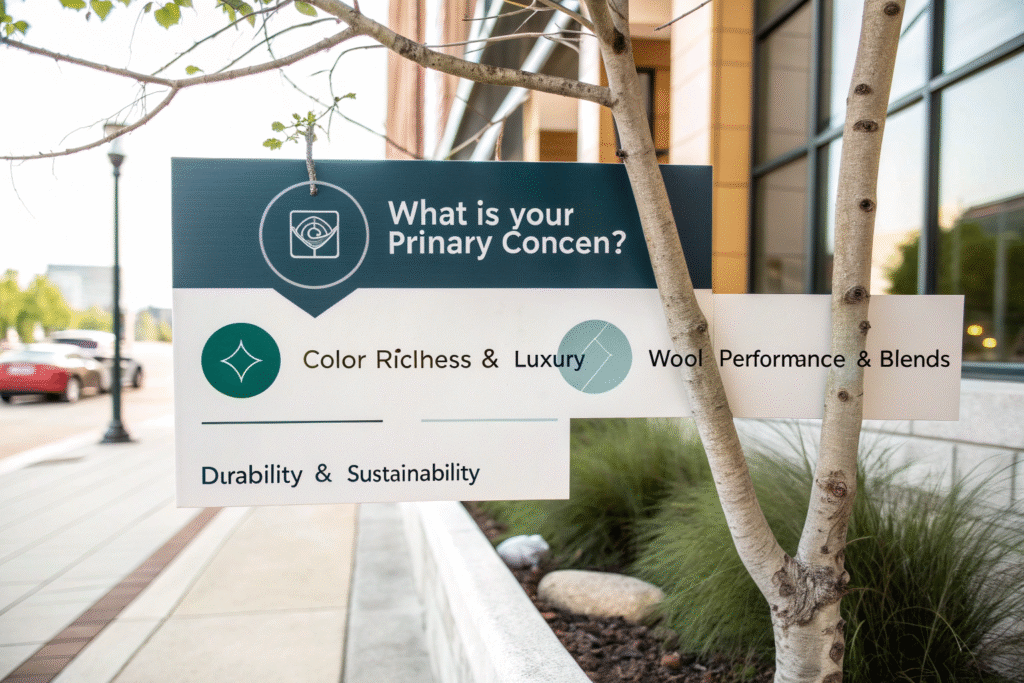

How to choose the right dyeing method for your project?

Choosing the right dyeing method depends on a careful balance of your project's priorities. You need to consider fiber content, desired aesthetic, performance requirements, budget, and lead time. There is no one-size-fits-all answer. The best choice is the one that aligns with your brand's values and your product's specific needs. Making the wrong choice can lead to product failure, returns, and brand damage. Let's compare the key factors to guide your decision.

| Factor | Fiber-Dyed | Top-Dyed | Solution-Dyed |

|---|---|---|---|

| Best For | Natural fibers (Cotton, Wool) | Wool & Wool Blends | Synthetic fibers (Polyester, Nylon) |

| Colorfastness | Excellent | Excellent | Superior (UV, Chlorine) |

| Lead Time | Longest | Long | Shortest |

| Cost | High | High | Competitive (at scale) |

| Sustainability | High water/energy use | High water/energy use | Low water/energy use |

| Minimum Order | High | Medium-High | Medium (for custom colors) |

What are the key questions to ask your supplier?

Before finalizing your choice, you must ask your supplier specific questions. Their answers will reveal their expertise and reliability. First, ask about quality control and certifications for colorfastness. Do they have test reports from SGS or other international standards? Second, inquire about their minimum order quantity (MOQ) for each dyeing method. Third, ask for lead time details, including sampling. Finally, discuss their experience with your specific fiber type and the end-use of your product. A professional supplier like Fumao will provide clear, transparent answers and data to support their recommendations.

Can dyeing methods be combined in one fabric?

Yes, dyeing methods can be creatively combined in a single fabric to leverage the strengths of each. A common example is a fabric made from a blend of solution-dyed yarn and fiber-dyed yarn. For instance, a denim might use a solution-dyed black polyester yarn for the warp (providing durability and fade resistance) and a fiber-dyed indigo cotton yarn for the weft (providing the classic denim look and feel). This hybrid approach allows designers to achieve unique aesthetic and performance characteristics that would be impossible with a single dyeing method.

Conclusion

Understanding the differences between fiber-dyed, top-dyed, and solution-dyed fabrics is more than a technical exercise—it's a strategic business decision. Fiber-dyeing offers unmatched color depth for natural fibers, top-dyeing is the gold standard for premium wool, and solution-dyeing provides unparalleled durability and sustainability for synthetics. Your choice directly impacts your product's quality, cost, and environmental footprint. In today's competitive market, leveraging the right dyeing technique can become your unique selling point, setting your brand apart.

We at Fumao Textiles International have over 20 years of experience guiding global clients through these exact choices. Our integrated supply chain, from our CNAS-certified lab to our weaving and dyeing partners, allows us to execute all these methods with precision and efficiency. We don't just sell fabrics; we co-create value by ensuring you get the right material for your success. If you are ready to produce your next clothing order with expertly dyed fabrics, contact our Business Director, Elaine. She will connect you with the right solutions for your needs. Reach out to Elaine at elaine@fumaoclothing.com.