Lace is the crown jewel of fashion, adding elegance and intricate detail to everything from bridal gowns to everyday apparel. But for buyers and designers, not all lace is created equal. The choice between different types, like Raschel and Crochet lace, can significantly impact your garment's cost, durability, and overall aesthetic. Making the wrong choice can lead to production delays, budget overruns, and a final product that doesn't meet your quality expectations. So, how do you navigate this delicate decision?

Understanding the fundamental differences between Raschel and Crochet lace is the first step to making an informed choice for your collection. Raschel lace is a machine-made fabric known for its efficiency and versatility, while Crochet lace is a hand-crafted textile prized for its unique, artisanal quality. The core distinction lies in their production method: one is industrialized for scale and speed, and the other is manual, emphasizing craftsmanship. This difference dictates everything from price and texture to design possibilities and lead times.

As a fabric supplier with over two decades in the heart of China's textile district, I've seen how this knowledge empowers our clients. Let's unravel the specifics of these two popular laces, ensuring your next design is both beautiful and commercially smart.

What is Raschel lace fabric?

If you've ever purchased a garment with intricate lace detailing at an accessible price point, you've likely encountered Raschel lace. This type of lace is a cornerstone of modern mass production, allowing designers to incorporate complex patterns without the exorbitant cost of handcrafted alternatives. But what exactly is it, and why is it so prevalent in today's market?

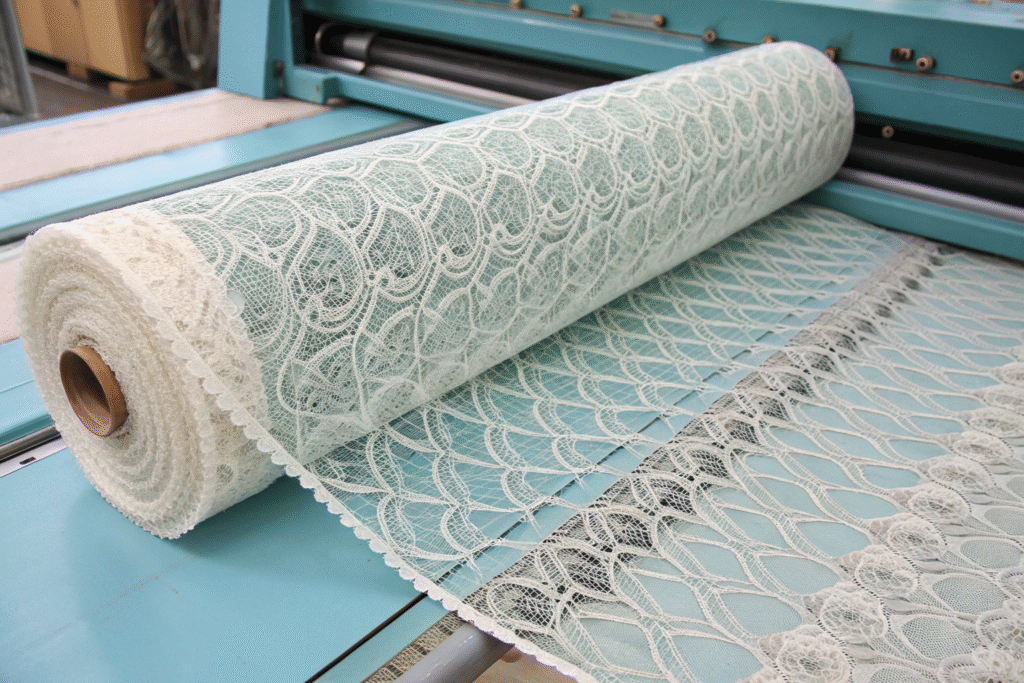

Raschel lace is a type of warp-knitted fabric produced on a specialized Raschel machine. Unlike weaving, which involves interlacing yarns at right angles, warp knitting loops yarns vertically, creating a stable and often elastic fabric. This method allows for the creation of large, continuous rolls of lace with elaborate patterns at a remarkably fast pace. Its efficiency makes it a go-to choice for large-scale fashion brands, lingerie, and home textiles.

How is Raschel lace manufactured?

The production of Raschel lace begins with a technical design fed into a computer-controlled Raschel knitting machine. These machines use multiple guide bars, each controlling a set of warp yarns. The bars move in complex, pre-programmed sequences to loop the yarns around the needles, forming the lace's net background and the denser pattern simultaneously in one integrated process. This is a key advantage, as it eliminates the need for separate construction and embroidery steps. The resulting fabric is characterized by a distinct, often geometric pattern on a ground mesh. The process is highly efficient, enabling the production of vast quantities of lace with consistent quality, which is crucial for meeting tight deadlines for major retailers.

What are the common uses of Raschel lace?

Due to its durability and cost-effectiveness, Raschel lace has a wide range of applications. It is extensively used in the lingerie industry for bras, panties, and teddies, where its slight stretch provides comfort and fit. In apparel, it is a popular choice for overlays on dresses, sleeves on blouses, and trims on evening gowns. Beyond fashion, its robustness makes it suitable for home furnishings such as curtain panels, tablecloths, and decorative pillow trims. The ability to incorporate synthetic fibers like polyester and nylon also makes it resilient for items that require frequent washing, aligning with the demands of fast fashion and functional home decor.

What is Crochet lace fabric?

Crochet lace stands in stark contrast to its machine-made counterpart, representing a tradition of handicraft that dates back centuries. It is the embodiment of artistry and patience in the textile world. For buyers seeking a unique, high-end, or bohemian look for their collections, Crochet lace offers an irreplaceable charm that machines cannot replicate.

Crochet lace is a handcrafted fabric created using a single crochet hook to interloop yarn or thread. The artisan builds the lace one stitch at a time, forming chains and loops into intricate patterns. This manual process allows for incredible flexibility and organic variation, meaning no two pieces are exactly identical. This uniqueness is its greatest selling point, appealing to designers of luxury, artisan, and niche boutique brands where individuality is prized over uniformity.

How is traditional Crochet lace made?

The creation of traditional Crochet lace is a meticulous and time-intensive artisanal process. An artisan uses a single crochet hook to pull a loop of thread through another loop, building a chain. By varying the type and placement of stitches—such as single, double, or treble crochet—complex motifs like flowers, leaves, and scalloped edges are formed. Unlike the integrated production of Raschel lace, Crochet often involves creating individual motifs that are later joined together with a connecting mesh or thread. This hands-on approach requires significant skill and time, making it a more expensive option. However, it results in a highly textured, three-dimensional fabric with a soft, irregular drape that is difficult to achieve by machine.

Where is Crochet lace typically applied?

Crochet lace is favored in applications where its artisanal quality can be showcased. It is a hallmark of high-end bohemian fashion, seen on designer blouses, festival wear, and premium resort collections. Its classic, romantic feel makes it a perennial favorite for bridal wear, particularly on veils, sleeves, and appliqués. In the realm of accessories, it is used for delicate shawls, gloves, and trims on linen tableware, adding a touch of handmade luxury. Because of its delicate nature and higher cost, it is less common in mass-market apparel but is a key differentiator for brands targeting a discerning, value-conscious clientele who appreciate craftsmanship.

Raschel vs Crochet lace: A detailed comparison for buyers

Choosing between Raschel and Crochet lace is not just an aesthetic decision; it's a strategic business choice. The right selection balances design intent with practical considerations like budget, timeline, and target market. For buyers sourcing from China, understanding these differences is crucial for effective communication with suppliers and ensuring the final product meets all specifications.

The primary difference lies in production: Raschel is machine-made, offering speed, consistency, and lower cost, while Crochet is hand-made, offering uniqueness, texture, and a higher price point. This fundamental distinction cascades into every aspect of sourcing, from minimum order quantities to lead times. A clear grasp of these factors prevents misunderstandings and streamlines the production process.

What are the key differences in production and cost?

The production and cost differences are the most significant factors for buyers. The following table breaks down the key distinctions:

| Feature | Raschel Lace | Crochet Lace |

|---|---|---|

| Production Method | Machine-made, warp-knitted | Handmade with a crochet hook |

| Production Speed | Very fast (meters per hour) | Very slow (hours per meter) |

| Cost | Low to moderate | High |

| Design Consistency | High; every meter is identical | Low; each piece has unique variations |

| Minimum Order Quantity (MOQ) | Low; suitable for bulk orders | High; often requires special arrangement |

As the table shows, Raschel lace is the clear choice for large-volume orders where budget and timeline are critical. Its mechanized production allows for low MOQs and predictable pricing. Conversely, Crochet lace involves skilled labor, which is slower and more expensive. Sourcing Crochet lace often requires higher MOQs to justify the artisans' time, making it better suited for limited editions or high-margin products.

How does texture and durability compare?

The texture and durability of the two laces are direct results of their manufacturing processes. Raschel lace, being machine-knitted, has a uniform and flat texture. While it can mimic various patterns, it often lacks the pronounced three-dimensionality of crochet. Its durability is generally higher, especially when made from synthetic fibers like polyester; it can withstand machine washing and frequent wear without losing its shape.

Crochet lace, on the other hand, is inherently textured and dimensional. Each stitch is a loop that stands away from the fabric base, creating a soft, tactile surface. However, this beautiful texture comes with a trade-off in durability. The open, looped structure is more delicate and can be prone to snagging. It often requires gentle hand washing or dry cleaning to maintain its appearance over time. For buyers, this means considering the garment's end-use—Raschel for everyday durability, Crochet for special occasion luxury.

How to choose the right lace for your fashion line?

Making the final decision on which lace to use is a critical step that aligns your creative vision with your business strategy. There is no universally "better" option; the best choice depends entirely on the goals of your specific collection. By asking a few key questions, you can confidently select the lace that will bring your designs to life while meeting your commercial objectives.

The choice boils down to your brand's positioning, target price point, and production timeline. If your brand is built on fast-fashion, high-volume turnover, Raschel lace is your most practical partner. If your brand identity revolves around artisan craftsmanship, uniqueness, and luxury, then the investment in Crochet lace will pay dividends in brand perception and customer loyalty.

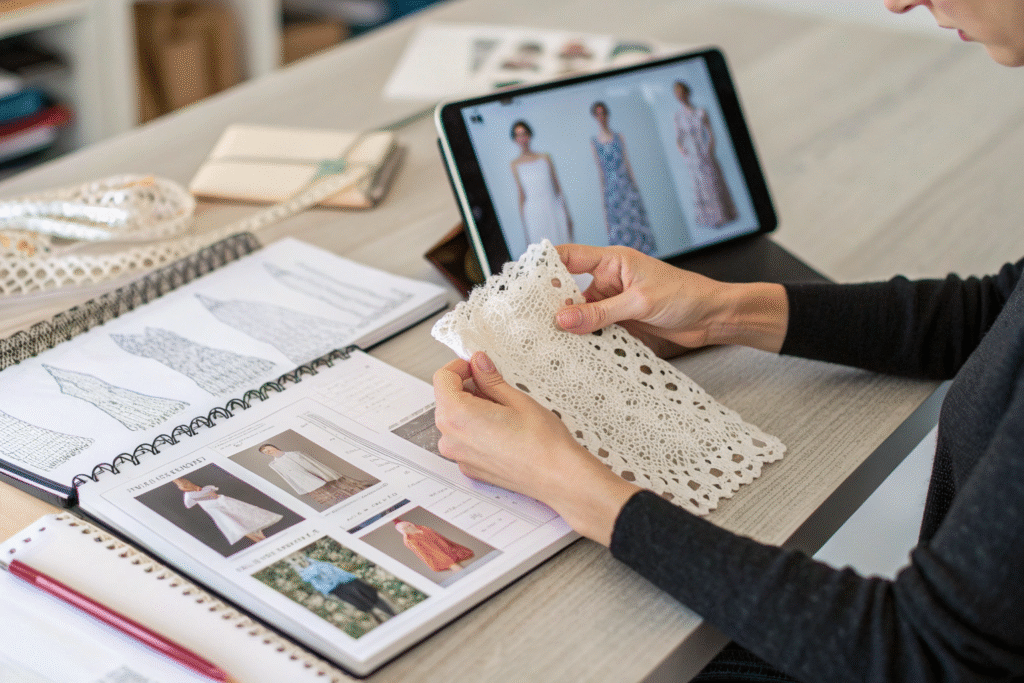

What questions should you ask your fabric supplier?

When sourcing lace, especially from an international supplier like us, clear communication is paramount. To ensure you get exactly what you need, always ask these key questions:

- "Can you provide a physical swatch?" Digital photos can be misleading. A physical sample allows you to feel the weight, drape, and texture.

- "What is the fiber content?" This affects the fabric's hand feel, dyeability, and care instructions. Is it natural cotton or synthetic polyester?

- "What are the exact MOQs for this design?" MOQs can vary significantly between Raschel and Crochet, and even within different complexities of Raschel patterns.

- "What is the production lead time for a bulk order?" This is crucial for planning your collection's launch. Raschel will have a much shorter lead time.

- "Do you have certifications for the dyes and materials?" Especially important for eco-conscious brands, ensuring compliance with standards like OEKO-TEX® or GOTS.

Asking these questions will help you avoid surprises and build a strong, transparent relationship with your supplier. A reliable partner will welcome these inquiries and provide detailed, helpful information.

When should you choose Raschel over Crochet (and vice versa)?

Let's simplify the decision-making process with clear scenarios.

Choose Raschel Lace if:

- You are producing for the mass market or large retail chains.

- Your budget is a primary constraint.

- You need a quick turnaround to catch a fashion trend.

- Consistency across thousands of garments is non-negotiable.

- The garment requires durability for frequent washing and wear.

Choose Crochet Lace if:

- Your brand is premium, boutique, or artisan-focused.

- Uniqueness and texture are key selling points for your collection.

- You are producing a limited edition or a high-value capsule collection.

- Your design is for a special occasion like bridal or evening wear where luxury is expected.

- Your customers value the story of handmade craftsmanship and are willing to pay for it.

Conclusion

In the world of textiles, understanding the distinction between Raschel and Crochet lace is a powerful tool for any fashion buyer or designer. Raschel lace offers the efficiency, affordability, and consistency required for large-scale production, making modern fashion accessible. Crochet lace provides the unparalleled texture, artistry, and uniqueness that define luxury and artisan collections. The choice isn't about which is objectively better, but which is perfectly suited to bring your specific creative and commercial vision to life.

At Fumao Textiles, nestled in China's textile hub of Keqiao, we specialize in guiding our clients through these exact decisions. With access to both advanced Raschel knitting facilities and a network of skilled artisans for Crochet work, we provide end-to-end fabric solutions. We ensure you get the right lace, with the quality, price, and lead time that matches your brand's needs. Ready to weave elegance into your next collection? Let's collaborate. Contact our Business Director, Elaine, today at elaine@fumaoclothing.com to discuss your fabric requirements and discover how we can help you create something extraordinary.