As a garment manufacturer with years of experience, I've seen fabric trends come and go. But one question we consistently get from our American brand partners is about bonded fabric. Many have heard the term, especially when looking for high-performance outerwear or sophisticated structured garments, but they are not always clear on what it entails or why it might benefit their collection. Understanding the materials you use is fundamental to creating quality apparel that stands out in a competitive market.

Bonded fabric is a composite material created by permanently adhering two or more separate layers of fabric together using an adhesive or thermal process. This production method enhances the fabric's properties, resulting in a material that is more stable, durable, and often functionally superior to single-layer textiles. The bonding technique allows designers to combine different materials, like a fashion outer shell with a warm insulating lining, into a single, easier-to-work-with fabric. This process is crucial for achieving the specific performance and aesthetic characteristics demanded by today's discerning consumers.

Let's delve into the world of bonded fabrics. We will explore its definition, the detailed production process, its significant advantages for your brand, and how to select the right partner for your bonded fabric needs.

What Exactly is Bonded Fabric?

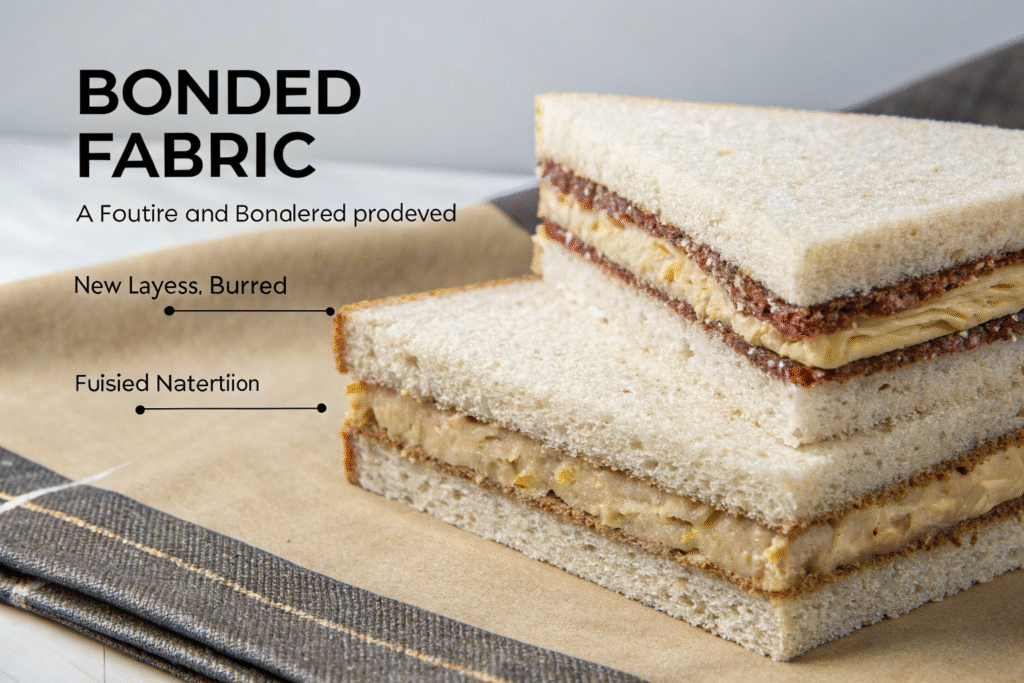

Bonded fabric is not a specific type of fiber like cotton or polyester, but rather a construction method. Think of it as a sandwich. You have two (or more) layers of fabric that are fused together to create a new, unified material. This is different from a simple lining that is stitched in; bonded layers are inseparable under normal conditions. This technology is widely used in applications where fabric performance is critical.

The primary purpose of bonding is to combine the beneficial properties of different materials. For instance, a common combination is a outer shell made of durable nylon for weather resistance, bonded to a soft, breathable polyester mesh on the inside. This creates a single fabric that offers both protection and comfort. The technical textiles industry heavily relies on bonding to achieve specific functional goals, such as waterproofing, insulation, and enhanced durability.

How does bonded fabric differ from laminated fabric?

This is a common point of confusion. While both involve layering, the key difference lies in the result and application. Fabric lamination typically involves applying a very thin film or coating to a single fabric layer to impart a specific property, like creating a waterproof fabric barrier. The laminate is a coating. Bonding, however, joins two complete layers of fabric. Lamination is often about adding a function to a base cloth, while bonding is about creating a new composite structure with the combined attributes of two distinct fabrics.

What are the most common types of bonded fabrics?

Bonded fabrics can be categorized by their composition and intended use. The main types include foam-bonded fabrics (where a layer of foam is adhered to fabric for insulation and loft), film-bonded fabrics (which incorporate a membrane for waterproofness), and fabric-to-fabric bonding (which combines two woven or knitted materials for structure and stability). Many high-performance athletic apparel products use a form of fabric-to-fabric bonding to manage moisture and provide support without adding bulk.

The Step-by-Step Bonded Fabric Production Process

The production of bonded fabric is a precise and technical process that requires specialized machinery and strict quality control. At our factory, we follow a meticulous multi-stage procedure to ensure every meter of bonded fabric meets the highest standards. The process can be broken down into three key stages: preparation, bonding, and curing.

First, the separate fabric layers are prepared. They are inspected for defects and fed onto the bonding machine. An adhesive is then applied to one of the fabric layers. The type of adhesive is critical—it can be a water-based paste, a thermoplastic powder, or a heat-activated web. The choice depends on the fiber content of the fabrics and the desired final hand feel and performance. For example, a polyurethane coating is often used for a flexible and durable bond on a wide range of materials.

What happens during the actual bonding stage?

In the bonding stage, the two fabric layers are carefully brought together under controlled heat and pressure. They pass through a series of heated rollers or a large press. The heat activates the adhesive, causing it to melt and flow between the fibers of both fabrics. The pressure ensures uniform contact and a consistent bond across the entire surface. This step is where the magic happens, transforming two independent pieces into one cohesive unit. The machinery settings must be perfectly calibrated to avoid issues like delamination or stiffening.

Why is curing and finishing so important?

After bonding, the fabric enters a curing chamber. Here, it is subjected to a specific temperature for a set duration. This curing process allows the adhesive to fully set and achieve its maximum strength. Once cured, the bonded fabric is cooled and inspected. Quality checks are vital. We test for bond strength, colorfastness after heat exposure, and overall durability. Only after passing these rigorous tests does the fabric move to the cutting room for garment production. Skipping or rushing these steps is a primary reason some suppliers deliver substandard bonded materials.

Key Advantages of Using Bonded Fabric in Your Apparel Line

Choosing bonded fabric for your clothing line offers tangible benefits that can enhance your product's market appeal and performance. The advantages extend beyond just the functional aspects to include significant improvements in manufacturing efficiency and final garment quality. This is why many leading brands are increasingly incorporating bonded materials into their collections.

The most immediate benefit is the superior structure and stability it provides. Bonding prevents the inner and outer layers of a garment from shifting against each other. This eliminates issues like lining twist in jackets or bunching in skirts, resulting in a cleaner drape and a more premium look. The fabric itself becomes more resilient to wrinkling and stretching, which is a key selling point for professional wear and travel clothing. The improved durability means the garment maintains its shape and appearance over a longer lifespan, increasing customer satisfaction.

How does bonding enhance aesthetic and design possibilities?

Bonding opens up new avenues for design innovation. Designers can create sharp, defined silhouettes that are difficult to achieve with traditional unlined fabrics. It allows for the use of delicate or sheer outer fabrics by backing them with a more substantial layer, adding opacity and body without compromising the intended aesthetic. This technique is revolutionary for high fashion pieces that require a unique texture or form. Furthermore, by eliminating the need for separate lining and the associated stitching, designers can often create cleaner, more minimalist designs with fewer seams.

What are the functional and production efficiencies?

From a functional standpoint, bonding is key to weatherproofing. It creates a windproof and often waterproof barrier, making it ideal for outerwear manufacturing. From a production perspective, it streamlines the manufacturing process. Handling a single piece of bonded fabric is faster and easier than handling and sewing two separate layers. This can lead to reduced labor costs and shorter production times. However, it requires a factory with expertise in working with these materials to avoid pitfalls like needle gumming from adhesive.

How to Choose a Reliable Bonded Fabric Manufacturer

Selecting the right manufacturing partner for your bonded fabric garments is perhaps the most critical step. The complexity of the bonding process means that not all factories possess the necessary equipment, technical knowledge, or quality control standards. A poor choice can lead to delayed shipments, inferior quality, and ultimately, a failed product line. Based on my experience, here are the key factors to consider.

First and foremost, verify the factory's technical capability. Do they have in-house bonding machines, or do they outsource this step? In-house control is always preferable as it allows for better quality oversight. Ask about their experience with different types of adhesives and fabrics. A competent manufacturer will not only execute the process but also advise you on the best combination of materials for your design and budget. They should have a clear understanding of international quality control standards for bonded fabrics.

What questions should you ask about quality assurance?

Directly ask about their testing protocols. A reliable partner will have a dedicated lab for testing bond strength (e.g., peel test), wash durability, and colorfastness. They should be transparent about their results and willing to provide pre-production samples for your approval. Inquire about their experience with relevant social compliance and material certifications, which indicate a well-managed factory. Be wary of suppliers who are vague about their processes or unable to provide verifiable documentation.

Why are communication and logistics crucial?

As you know, inefficient communication is a major pain point. Your manufacturer must have a responsive, English-fluent team that provides regular updates. They should understand the importance of your timeline, especially for seasonal goods. Discuss their logistics management capabilities upfront. Do they handle documentation and shipping? Can they offer DDP (Delivered Duty Paid) terms to simplify the process for you? A partner that manages the entire process from fabric bonding to delivery to your door minimizes risk and saves you valuable time.

Conclusion

Bonded fabric is a powerful tool in the apparel industry, offering a unique blend of structure, functionality, and design potential. Understanding what it is and how it is produced empowers you to make informed decisions for your brand. From creating sleek, modern silhouettes to developing high-performance outerwear, the applications are vast. The key to success lies in partnering with a manufacturer that has the technical expertise, rigorous quality control, and reliable communication channels to bring your vision to life accurately and on time.

If you are looking to explore the possibilities of bonded fabric for your next collection, we invite you to partner with us. Our team is equipped with the technology and experience to guide you through every step. For a consultation on your specific needs, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let us help you create garments that stand out for their quality and innovation.