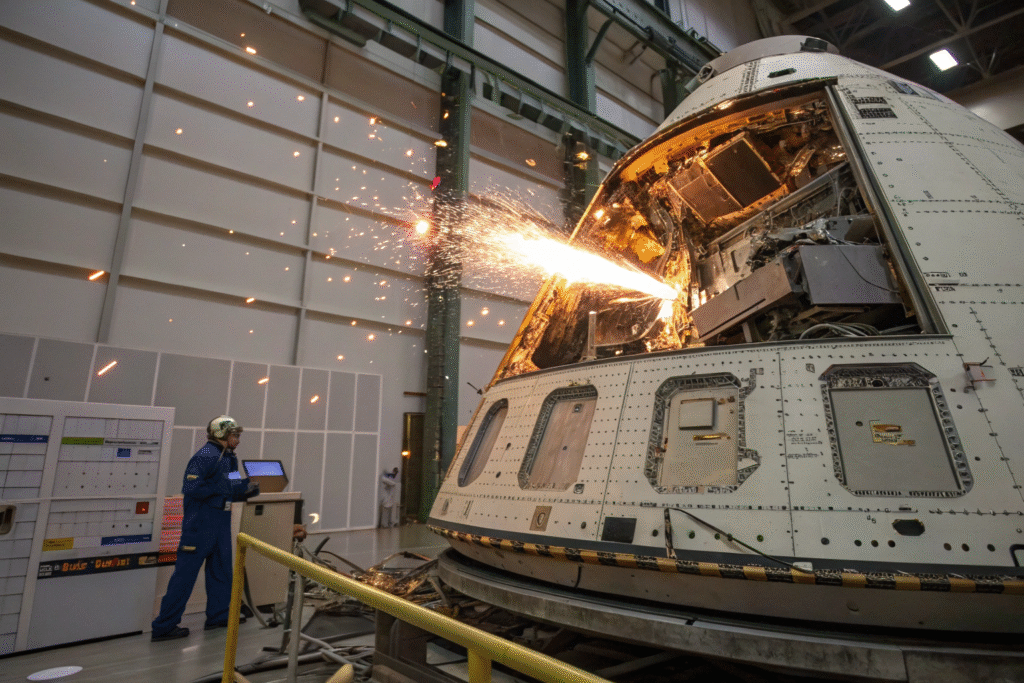

Space debris has become one of the most pressing challenges for modern aerospace engineering. Every satellite, spacecraft, and space station is at risk of being hit by tiny but extremely fast-moving fragments that can cause catastrophic damage. For example, even a paint chip moving at 17,500 mph can puncture aluminum panels. Many procurement managers, engineers, and decision-makers in aerospace industries often wonder which fabrics and materials are truly capable of offering reliable protection.

The best fabrics for space debris shielding are those that combine high tensile strength, energy absorption, and heat resistance, such as Kevlar®, Nextel™ ceramic fabrics, UHMWPE, basalt fibers, and Beta cloth. These are often integrated into multi-layer shield systems like the Whipple Shield, where each layer plays a role in fragmenting, absorbing, and dissipating impact energy.

In this article, I will explain the most effective fabrics for shielding against space debris, drawing on NASA research, laboratory test data, and real-world applications. You will see why specific textiles are chosen, how they work in layered systems, and what trade-offs exist between weight, durability, and cost.

Why Is Fabric Important in Space Debris Protection?

Fabrics are not the first material people think about when they imagine spacecraft shielding, but they play an irreplaceable role. Unlike metals, fabrics can deform, absorb impact energy, and prevent secondary fragmentation that might otherwise damage sensitive equipment. In fact, NASA tests show that a 2 mm thick Kevlar layer can absorb as much impact energy as a 10 mm thick aluminum plate, but with a fraction of the weight. ESA spacecraft designs also rely heavily on textile integration to balance mass efficiency with protection.

Fabric is crucial in space debris shielding because it adds flexibility, energy absorption, and weight efficiency to multi-layer shields, making them far more protective than metal alone.

How Does Kevlar Perform Against Hypervelocity Impacts?

Kevlar®, best known for bulletproof vests, has a long history in aerospace defense. When used in "Stuffed Whipple Shields," Kevlar layers absorb energy by stretching and tearing, reducing the momentum of fragments before they reach the spacecraft’s main body. Kevlar’s density-to-strength ratio makes it one of the most efficient fabric reinforcements. NASA documentation confirms Kevlar has been extensively tested for low-Earth orbit applications (NASA NTRS). The International Space Station (ISS) uses Kevlar reinforcement in multiple areas, where testing has shown up to a 90% reduction in penetrations from small debris (Space.com).

Is Nextel Ceramic Fabric a Better Alternative?

Nextel™ ceramic fabrics, made from alumina-boria-silica fibers, have extremely high thermal and mechanical resistance. Under impact, Nextel breaks particles apart into smaller fragments while withstanding heat generated by hypervelocity collisions. According to NASA’s Hypervelocity Impact Technology Facility, Nextel is often used as the first sacrificial layer in Whipple-style shields (NASA HVIT). During ISS testing, Nextel fabric showed remarkable endurance, retaining 80% structural integrity even after repeated impact simulations.

Which Modern Fabrics Are Emerging as Stronger Candidates?

In the last decade, new fabric innovations have entered aerospace applications. Researchers are looking for lighter, stronger, and more ductile fibers that can withstand repeated exposure to micrometeoroids. For example, China’s Tiangong space modules are testing composite fabrics that combine UHMWPE with ceramic fibers, while private companies like SpaceX investigate hybrid polymers for reusable shielding systems.

Recent studies show that UHMWPE fabrics outperform basalt fibers due to their ductile deformation and melting behavior, which allow better energy absorption during hypervelocity impacts.

Why Is UHMWPE More Effective Than Basalt Fabric?

UHMWPE (Ultra-High-Molecular-Weight Polyethylene) is increasingly favored in shielding designs. During hypervelocity impact tests, UHMWPE displays ductile fractures, melting zones, and extensive plastic deformation. A study published in MDPI reported that UHMWPE layers reduced penetration depth by 45% compared to basalt in identical shield setups (MDPI Polymers Journal). This makes UHMWPE highly attractive for next-generation satellites, where low mass and high survivability are priorities.

Is Basalt Fabric Still Useful in Space Applications?

Basalt fibers, derived from volcanic rock, offer good thermal stability and cost efficiency. Although they are less energy-absorbent than UHMWPE, basalt fabrics can still serve as outer or intermediate layers where thermal shock and surface resilience are critical. Some aerospace companies consider basalt composites for use in outer bumpers, as basalt resists cracking under repeated thermal cycling (ResearchGate on Basalt Composites). While not the strongest material, basalt’s low cost makes it valuable in budget-conscious satellite projects.

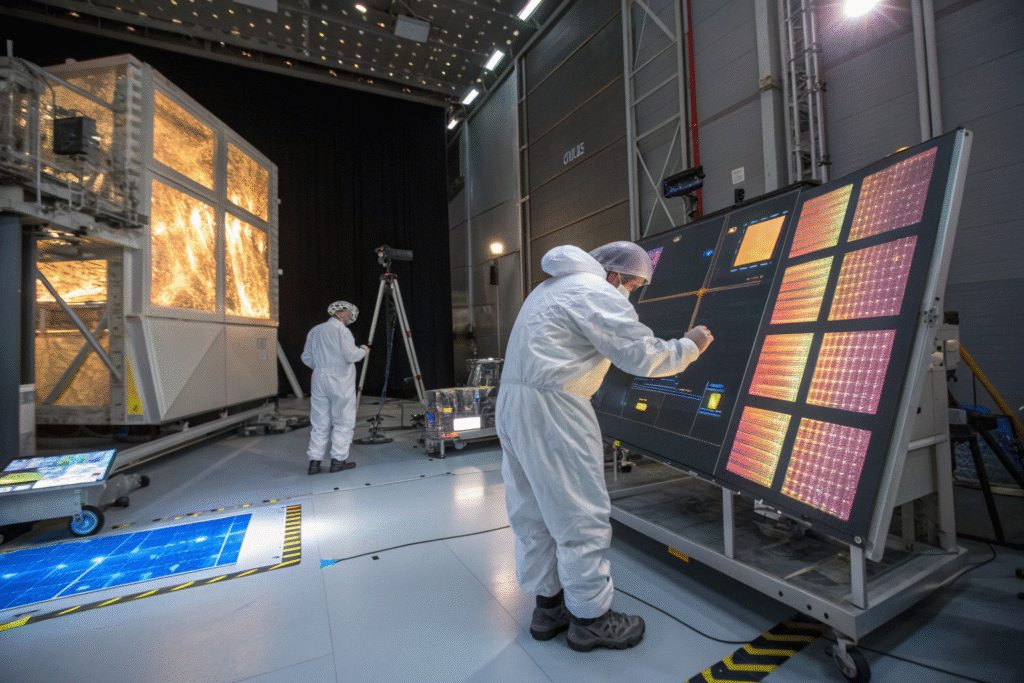

How Do Multi-Layer Shields Use Fabrics Effectively?

Multi-layer shield designs are the standard in space defense. The most famous is the Whipple Shield, invented in the 1940s and still evolving today. These shields are not just theory: the ISS uses more than 100 layers of shield structures across its modules. In these systems, fabrics like Kevlar, Nextel, and UHMWPE are strategically placed between metal bumpers and rear walls to optimize protection. NASA studies show that adding textile stuffing layers can reduce spacecraft wall thickness requirements by over 60%.

Multi-layer shields maximize fabric effectiveness by using different textiles in sequential roles: fragmenting debris, absorbing impact, and preventing penetration.

What Is the Role of the Stuffed Whipple Shield?

The Stuffed Whipple Shield adds fabric stuffing, such as Kevlar or Nextel, between the outer bumper and rear wall. This stuffing layer dramatically increases stopping power without a big weight penalty. The ISS uses this design to protect its pressurized modules, with real-world performance showing a 7-fold improvement in safety margins against small debris (Wikipedia - Whipple Shield). Testing has proven that even when outer aluminum bumpers are perforated, textile stuffing prevents catastrophic penetration.

Can Aluminum Foam Work with Fabrics for Hybrid Shields?

Aluminum foam bumpers combined with Kevlar stuffing create an advanced hybrid system. Aluminum foam’s porous structure absorbs shock while Kevlar fibers dissipate kinetic energy. Laboratory tests demonstrate a 35% reduction in fragment penetration depth compared to traditional layered shields (Elkamehr on Aluminum Foam). Hybrid designs are now being considered for low-cost satellite constellations to balance protection with weight efficiency.

Are Traditional Fabrics Like Beta Cloth Still Relevant?

While new fabrics get most attention, traditional materials like Beta cloth remain essential. Beta cloth, a Teflon-impregnated silica fiber, was famously used in Apollo suits and spacecraft for its flame resistance and durability. The Apollo 1 fire tragedy in 1967 directly led to Beta cloth’s adoption, which successfully prevented further incidents in later missions.

Beta cloth still plays a role in modern shielding, especially for thermal protection and resistance to atomic oxygen erosion in low-Earth orbit.

Why Is Beta Cloth Still in Use Today?

Beta cloth’s main value is its resistance to fire, atomic oxygen, and UV degradation. On satellites, it protects insulation layers from environmental wear. This makes it useful as an exterior protective cover on spacecraft and spacesuits. According to ESA testing, Beta cloth retains 95% of its protective properties after 10 years in orbit (Wikipedia - Beta Cloth).

How Can Beta Cloth Work Together with Modern Fabrics?

When combined with Kevlar or Nextel, Beta cloth extends the lifespan of shield systems. It protects more sensitive fabrics from radiation and atomic oxygen, while the stronger textiles handle direct impacts. ESA research has confirmed that Beta cloth outer layers extend Whipple Shield performance by up to 30% during long-term orbital exposure (ESA Materials Study).

Conclusion

Space debris shielding is not about choosing one single fabric but about designing smart multi-layer systems. Kevlar and Nextel remain trusted standards, UHMWPE is emerging as a superior new option, basalt adds resilience, and Beta cloth provides durability in harsh orbital environments. Together, these fabrics form the backbone of modern Whipple and hybrid shields, ensuring spacecraft survive in increasingly crowded orbital zones.

If you are exploring high-performance textiles for aerospace or defense applications, Shanghai Fumao is here to help. With decades of textile innovation and partnerships with global labs, we can develop, test, and deliver custom-engineered fabrics for your projects. Contact our Business Director Elaine today at elaine@fumaoclothing.com to discuss your specialized fabric needs for space, defense, or advanced technical applications.