In today’s global fabric industry, sourcing managers and brand buyers face constant challenges: fabrics that wear out too soon, functional textiles that lose properties after a few washes, and replacement cycles that cost both money and environmental resources. These pain points limit competitiveness in markets where durability and sustainability are key.

Self-healing ionic liquid embedded smart textiles provide an innovative solution by offering extended product life, automatic repair of damage, and sustainable performance. This technology integrates ionic liquids into fibers, giving fabrics the ability to self-repair micro-tears, maintain conductivity, and resist moisture stress.

As a fabric manufacturer with over 20 years of professional experience in Keqiao—the hub of the world’s textile cluster—I have witnessed how advanced textiles reshape buyer expectations. In this article, I explain why this next generation of smart fabrics is worth your consideration.

Benefits of Self-Healing Textiles

The first question many buyers ask is simple: “Why should I care about self-healing fabrics?” The answer lies in their ability to extend durability while lowering replacement costs.

Self-healing ionic liquid fabrics repair micro-damage automatically, keeping garments intact for longer usage cycles. This allows fashion, sportswear, and industrial buyers to save on sourcing budgets while reducing textile waste.

How Do These Fabrics Repair Themselves?

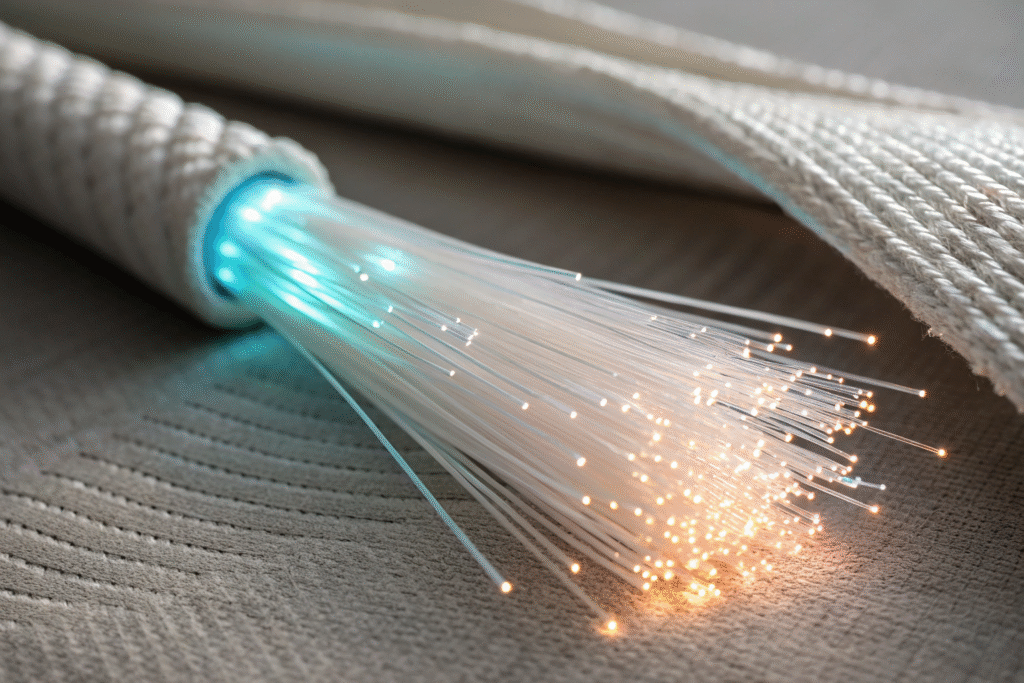

Self-healing fabrics use ionic liquids that flow within the fiber matrix. When surface scratches occur, the ionic components realign to close gaps. Studies on ScienceDirect textile innovations confirm that ionic liquids improve both conductivity and repair performance. Meanwhile, Nature Materials research demonstrates how ionic interactions allow long-lasting mechanical strength.

Can They Help Reduce Textile Waste?

Yes. The EPA estimates over 11 million tons of textiles are discarded annually in the U.S. Self-healing fabrics extend garment life, lowering disposal rates. Combined with recycled polyester or organic cotton, this approach supports circular production. Circular fashion strategies align perfectly with these textiles.

Applications Across Industries

Buyers across sectors—from sports brands to medical institutions—want materials that perform better and last longer.

Ionic liquid embedded fabrics are applied in sportswear, medical garments, uniforms, and fashion apparel. Their adaptability gives brands new ways to integrate performance features into daily products.

How Are They Used in Sportswear?

Sportswear demands elasticity, durability, and moisture management. Ionic fabrics maintain moisture-wicking properties while self-repairing from abrasions. Their conductivity also supports integration with wearable technology, making them ideal for connected fitness gear.

What About Medical or Protective Textiles?

Healthcare uniforms and protective gear require antibacterial properties and resilience. According to NIH studies, ionic smart fabrics deliver antibacterial benefits and enhanced durability. In defense gear, longer service life reduces procurement costs, while NIOSH standards ensure compliance with safety regulations.

Sustainability and Environmental Impact

Today’s global buyers prioritize fabrics that meet eco-certifications. Self-healing ionic fabrics bring both durability and environmental responsibility.

By extending garment lifespans, these textiles help reduce waste and carbon emissions. They also align with sustainable sourcing standards widely recognized in Europe and the U.S.

How Do They Fit Into Circular Fashion?

Self-healing fabrics reduce disposal needs and support Ellen MacArthur Foundation’s circular economy. When combined with recycled fibers, they improve ESG scores, an important factor for global apparel buyers.

Are Ionic Liquids Safe for the Environment?

Many ionic liquids are recyclable and non-toxic. According to OEKO-TEX, fabrics can be tested and certified safe for consumers. Their recyclability makes them compatible with sustainable production models. Global organic textile standards further ensure compliance for eco-conscious buyers.

Challenges and Future Outlook

Every innovation faces adoption barriers. For self-healing fabrics, costs and production scaling remain the main concerns.

While current prices are higher, the long-term savings from reduced waste and extended use make them a strong investment.

Are They Expensive to Produce Now?

Yes. As Textile World reports, production costs are higher today. But prices are expected to fall with scaling and new processing techniques. Brands investing now secure early adoption advantages.

What Is the Future Potential?

According to MarketsandMarkets, smart textiles are projected to grow at double-digit rates. In China’s Keqiao cluster, factories are expanding capacity for these fabrics. With continued R&D, wider adoption in global fashion and technical textiles is inevitable.

Conclusion

Self-healing ionic liquid embedded smart textiles are more than an academic concept. They are practical, scalable, and ready to solve real-world problems of durability, sustainability, and performance. For buyers in fashion, sportswear, and industrial sectors, this innovation provides a clear competitive edge.

If you are considering integrating such textiles into your product line, Shanghai Fumao offers comprehensive support—from laboratory development to bulk production and global logistics. Please connect with our Business Director Elaine at elaine@fumaoclothing.com to begin your own journey into self-healing smart fabrics.