Outside the nuclear field, fabric means cotton or silk. In fusion research, it refers to plasma-facing materials (PFMs) that protect reactor walls. These fabrics must withstand extreme heat, resist erosion, and minimize tritium retention to keep plasma stable.

The best fabrics for plasma confinement are tungsten, liquid lithium, ceramics, and engineered composites. Each offers strengths and challenges, and the choice depends on balancing durability, safety, and engineering feasibility.

Why Is Tungsten Considered the Gold Standard?

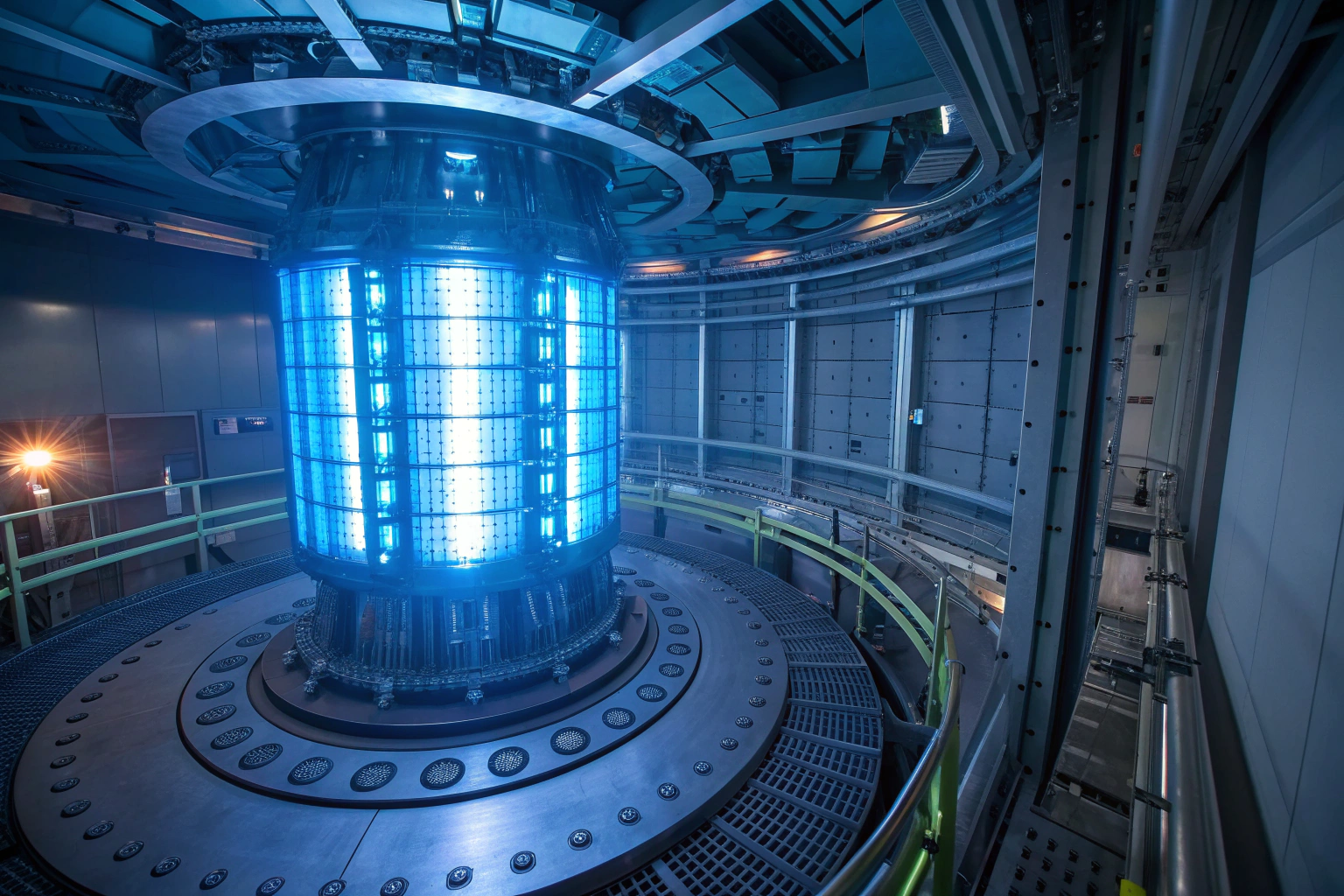

Fusion walls face heat fluxes hotter than the sun and constant neutron bombardment. Tungsten has emerged as the most reliable fabric because it resists both extreme temperatures and erosion.

Tungsten is preferred for its very high melting point, strong thermal conductivity, and low sputtering rate, making it central to ITER and other projects.

Tungsten withstands more than 3,400°C and holds less tritium than carbon, improving safety. Its weaknesses are neutron-induced embrittlement and surface “fuzz” formation. To solve this, researchers are developing tungsten alloys, nanoporous structures, and composites for improved resilience.

Are Liquid Metals the Future of Plasma Fabrics?

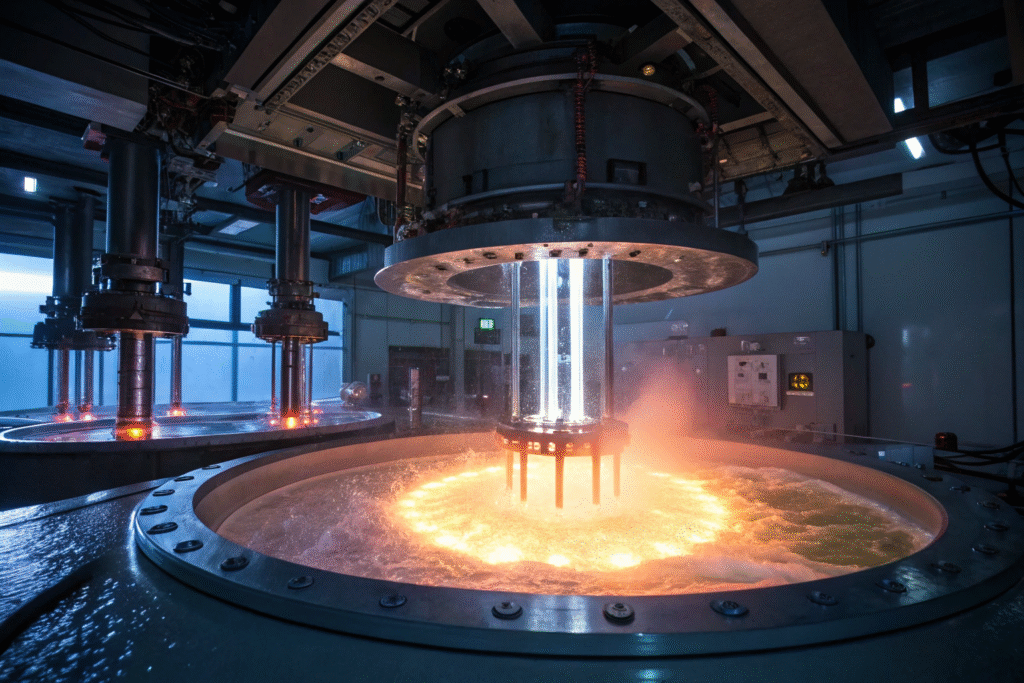

Unlike solid walls, liquid metals such as lithium can flow, absorb heat, and repair damage, making them highly attractive for next-generation reactors.

Liquid lithium lowers hydrogen recycling, improves confinement, and manages heat loads better than most solids.

Lithium’s low atomic number reduces radiation losses, and experiments confirm its stabilizing effect on plasma. The challenge lies in handling its chemical reactivity and designing pumps and flow systems that work reliably in a reactor environment. Despite this, liquid lithium is one of the strongest candidates for future DEMO reactors.

Why Was Graphite Abandoned as a Plasma Fabric?

Graphite was once widely used because it was cheap and easy to produce. But its drawbacks soon outweighed its advantages.

Graphite erodes rapidly and traps large amounts of tritium, creating safety and efficiency problems.

Trapped tritium makes fuel recovery harder and raises safety concerns. For this reason, graphite is no longer used in large-scale reactors, although smaller experiments may still adopt it for cost reasons. With stricter safety demands, its role in future devices is very limited.

Can Advanced Ceramics and Composites Replace Metals?

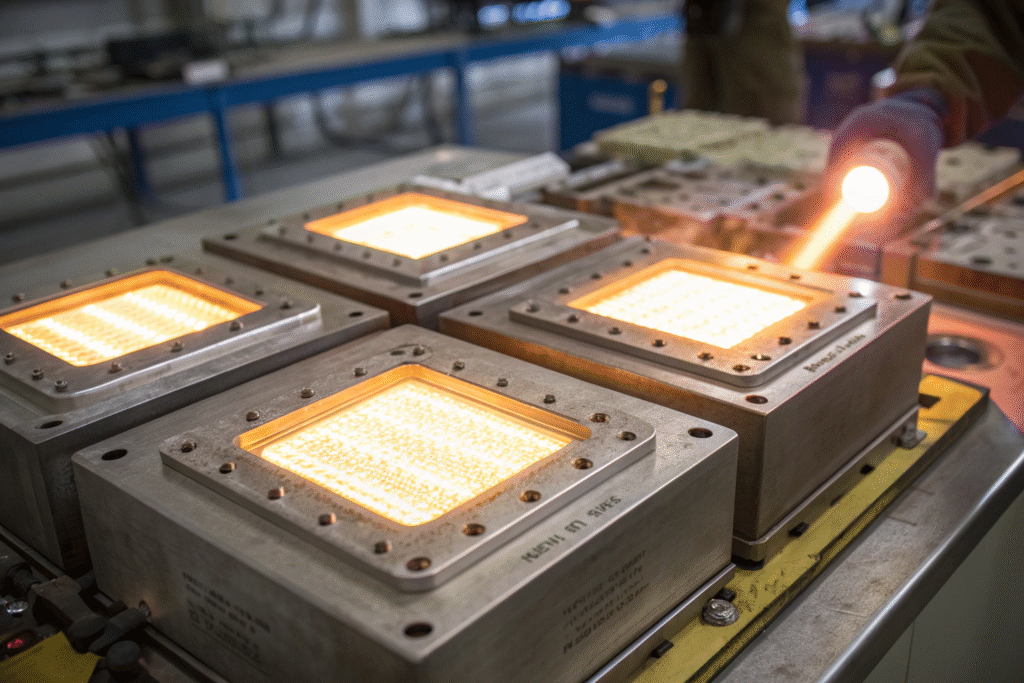

New solutions are being explored beyond metals. Ceramics and composites offer high heat resistance and lower activation under neutron exposure.

Materials like silicon carbide, borides, and nanoporous tungsten composites show strong potential but remain experimental.

Ceramics are stable at high temperatures, and some become less radioactive after neutron exposure. Tungsten composites with borides resist cracking and neutron flux better than pure tungsten. Nanoporous structures also improve durability by absorbing stress. These innovations are not yet ready for ITER but may define DEMO and future reactors.

Conclusion

The best fabrics for plasma confinement are advanced materials designed for extreme conditions. Tungsten is the most proven option, lithium offers self-healing potential, graphite has been phased out, and ceramics with composites represent the next frontier.

Fusion’s future depends on these fabrics as much as on magnetic fields. Every new material tested brings us closer to making fusion energy practical.

If you are interested in how advanced material manufacturing can shape the future of clean energy, you can also contact our company, Shanghai Fumao, to explore collaborations. For fabric development partnerships, reach out directly to our Business Director, Elaine, at elaine@fumaoclothing.com.