Hydrogen fuel cells are transforming clean energy, but what most people overlook is how much the right choice of fabric materials can influence safety, performance, and efficiency. Choosing the wrong fabrics can lead to poor conductivity, gas leakage, or even system failure. Buyers, engineers, and developers often struggle with identifying which fabrics deliver the best balance of durability, chemical stability, and conductivity.

The best fabrics for hydrogen fuel cells are typically advanced carbon-based and polymer-based textiles, such as carbon paper or cloth for gas diffusion layers, and fluoropolymer membranes like Nafion® for proton exchange membranes. These materials combine conductivity, chemical resistance, and long-term durability.

If you are considering hydrogen projects, understanding the role of fabrics in proton exchange membranes, gas diffusion layers, sealing, and hydrogen storage will help you make the best sourcing and design decisions.

Which Fabrics Are Used in Proton Exchange Membranes (PEM)?

Many challenges in hydrogen fuel cells come from the proton exchange membrane (PEM). If the membrane fabric is weak, it will degrade quickly and lead to high costs. This problem frustrates engineers and project managers trying to scale hydrogen systems.

In PEM fuel cells, perfluorosulfonic acid membranes like Nafion® are the most widely used fabrics, often reinforced with expanded PTFE (ePTFE) for added mechanical strength. These fabrics deliver high conductivity and strong chemical resistance.

The truth is, Nafion has been the gold standard for decades. But new competitors are developing membranes that are cheaper and more stable at higher temperatures.

Why is Nafion so widely used?

Nafion stands out because of its strong fluoropolymer structure. It resists chemical damage, which makes it last longer. The U.S. Department of Energy Hydrogen Program explains that reinforced Nafion membranes improve both efficiency and durability. Expanded PTFE membranes are often used to strengthen Nafion, ensuring it can handle pressure cycles.

Are there alternatives to Nafion membranes?

Yes. Newer hydrocarbon ionomers like polybenzimidazole (PBI) offer better thermal stability. Composite membranes that include inorganic fillers also help reduce costs. A review in the Journal of Power Sources shows that alternatives are becoming more competitive. 3M Fuel Cell Components also develops membranes that cut costs by using fewer fluoropolymers.

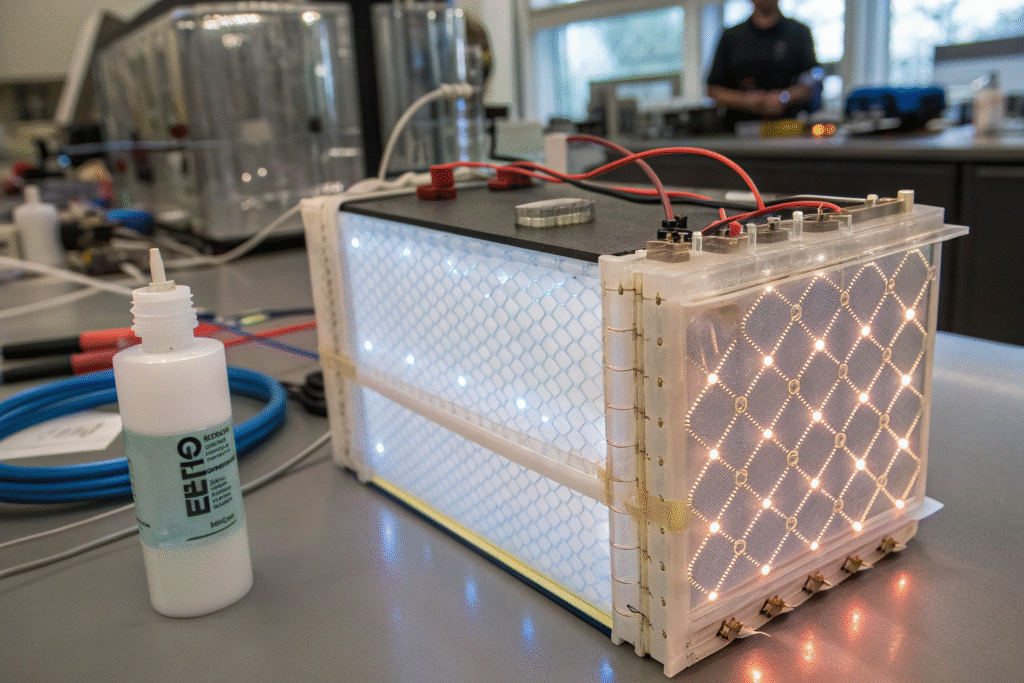

What Fabrics Are Used in Gas Diffusion Layers (GDLs)?

Hydrogen fuel cells cannot function well if gases do not spread evenly. Many systems fail because of poor gas distribution, and the choice of gas diffusion layer (GDL) fabrics is the key solution.

The best fabrics for GDLs are carbon fiber paper and carbon cloth. These fabrics combine porosity, conductivity, and water management properties, which are all vital for stable hydrogen fuel cell performance.

Carbon fabrics not only spread gases but also prevent water buildup. Without them, cells would flood and fail.

--

Why is carbon cloth effective for fuel cells?

Carbon cloth is flexible and customizable. Manufacturers weave it with different densities to manage gas and water flow. Companies such as Toray Carbon Paper and SGL Carbon Cloth provide widely used materials for PEMFCs. PTFE treatments make them hydrophobic, helping water move efficiently.

Are there performance differences between carbon paper and carbon cloth?

Yes. Carbon paper offers uniform thickness and works well in automotive fuel cells. On the other hand, carbon cloth provides flexibility and strength for research or stationary applications. Ballard Power Systems explains how the choice depends on the target system. Uniformity favors carbon paper, while flexibility makes carbon cloth attractive.

What Fabrics Ensure Safety and Sealing in Fuel Cells?

Even the best membranes and diffusion layers will fail if gases leak. Many hydrogen projects collapse because of poor sealing fabrics. This is why gasket and insulation materials are so important.

Fluoropolymer-coated fabrics such as PTFE, FEP, and PVDF, along with silicone-coated fiberglass, are commonly used for seals and gaskets. These ensure leak-tight and heat-resistant operation in hydrogen fuel cells.

These sealing fabrics are the silent heroes of hydrogen systems. Without them, leaks would make fuel cells dangerous.

--

Why are fluoropolymers ideal for sealing layers?

Fluoropolymers resist acid and heat. They remain stable even inside harsh hydrogen environments. Chemours PTFE Solutions lists many fuel cell sealing applications. Reinforced PTFE gaskets are also promoted by Parker Sealing Solutions.

Are there textile reinforcements for seals?

Yes. Silicone-coated fiberglass fabrics improve dimensional stability. These reinforcements prevent failure under pressure. Saint-Gobain High-Performance Fabrics and Flexitallic Gasket Materials provide several options for sealing layers.

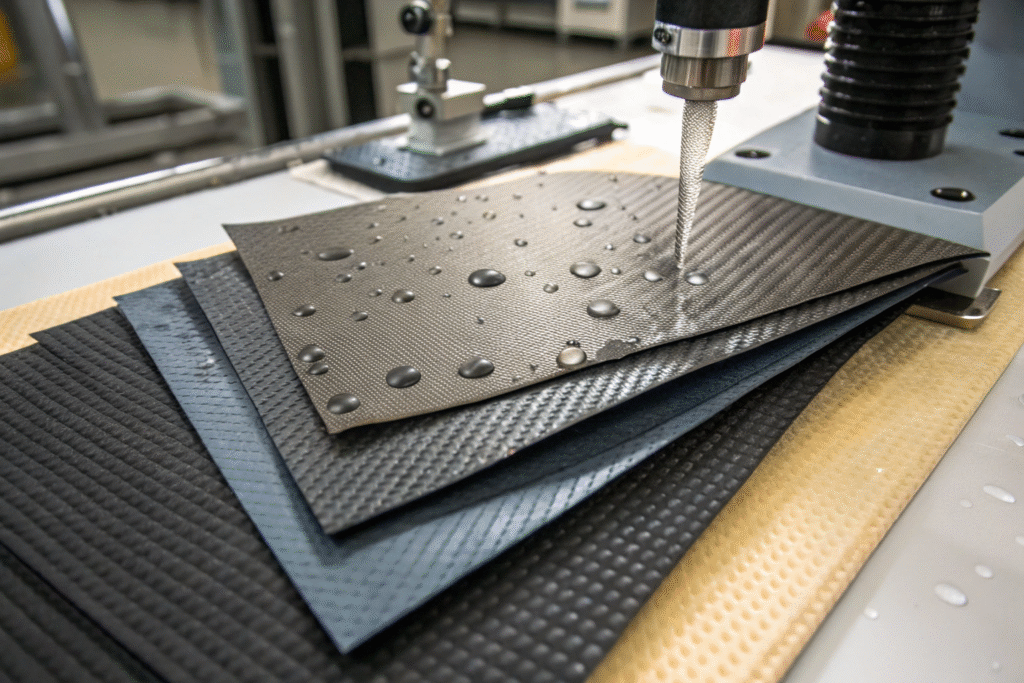

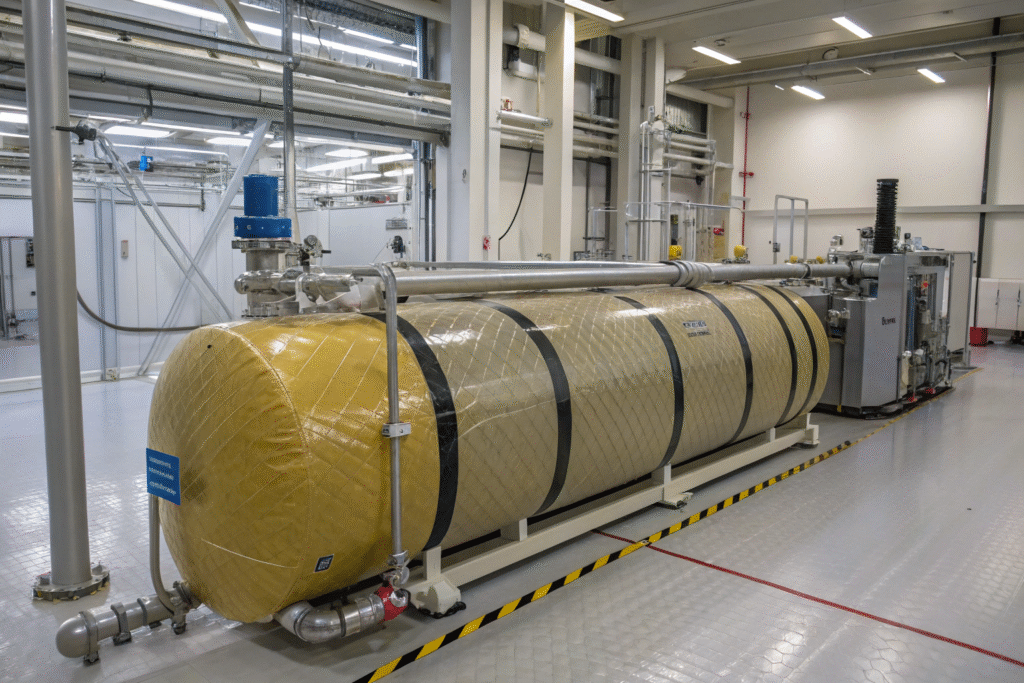

What Fabrics Are Used in Storage and Balance-of-Plant Components?

Hydrogen fuel cells extend beyond the stack. Tanks, pipes, and other support systems also need strong fabrics. Many failures happen because storage fabrics are weak under pressure.

Aramid (Kevlar®), carbon fiber composites, and PVDF-coated fabrics are essential for hydrogen storage vessels, piping, and balance-of-plant components. They keep systems safe under extreme pressure and chemical exposure.

With rising hydrogen demand, these fabrics ensure reliability in daily operation.

--

Why is aramid fabric important for hydrogen tanks?

Aramid fibers such as Kevlar® are strong and impact-resistant. They protect hydrogen tanks storing gases at 700 bar. Safety rules like SAE J2579 standards explain why aramid fabrics are necessary.

What role does PVDF play in balance-of-plant?

PVDF-coated fabrics resist chemicals and keep pumps and valves stable. Arkema Kynar® PVDF and Solvay Solef PVDF provide proven solutions. These materials extend the service life of hydrogen plants.

Conclusion

The right fabrics make hydrogen fuel cells work better and safer. From Nafion membranes to carbon diffusion layers, from fluoropolymer sealing fabrics to Kevlar composites, every layer matters. Choosing the right textile ensures safety, conductivity, and durability.

If you want to source advanced fabrics for hydrogen fuel cells or clean energy projects, we at Shanghai Fumao are ready to work with you. With our weaving, dyeing, coating, and inspection facilities, we can produce custom fabric solutions. Contact our Business Director Elaine at elaine@fumaoclothing.com to begin developing your hydrogen energy materials today.