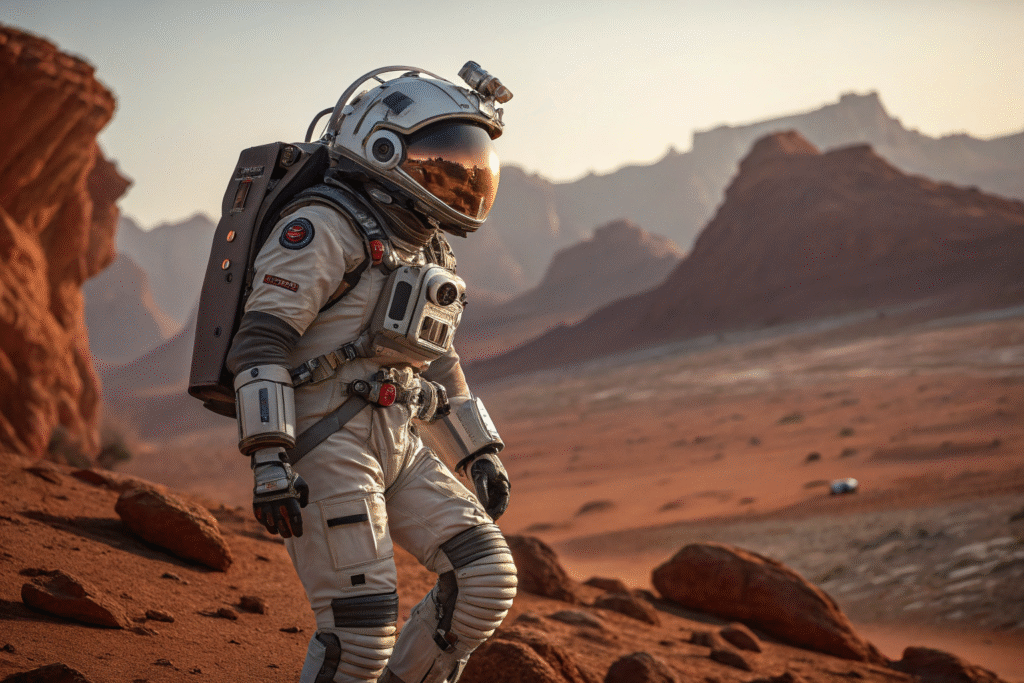

Space exploration pushes the limits of human safety. Astronauts face extreme temperatures, radiation, and the constant danger of micrometeoroids and sharp equipment edges that can tear through protective clothing. Traditional materials like Kevlar® and Nomex® offer high levels of durability, but they have limits in flexibility and cut-resistance. This is where Vectran® fiber becomes an essential innovation.

Vectran® fiber is a high-performance multifilament yarn spun from liquid crystal polymer (LCP), known for its superior cut resistance, abrasion durability, and thermal stability. These qualities make it a top choice for designing safer and more reliable cut-resistant space suits.

Space agencies and textile innovators look for the perfect balance between strength, flexibility, and long-term reliability. Let’s explore why Vectran® is becoming a cornerstone material in astronaut protective gear.

What Makes Vectran® Fiber Unique?

Vectran® is not just another synthetic fiber. Its unique liquid crystal polymer (LCP) structure sets it apart from common fibers used in aerospace textiles.

Vectran® fiber delivers a remarkable combination of strength, cut resistance, and thermal stability, making it ideal for space suit applications.

How Does Its Strength Compare to Other Fibers?

Vectran® has a tensile strength five times stronger than steel on an equal weight basis, rivaling materials like Kevlar®. However, unlike Kevlar, Vectran does not lose strength when exposed to moisture, which is a crucial factor for long-duration space missions. It also resists fatigue, offering long-lasting performance in the extreme environment of space.

Why Is Flexibility Important for Astronauts?

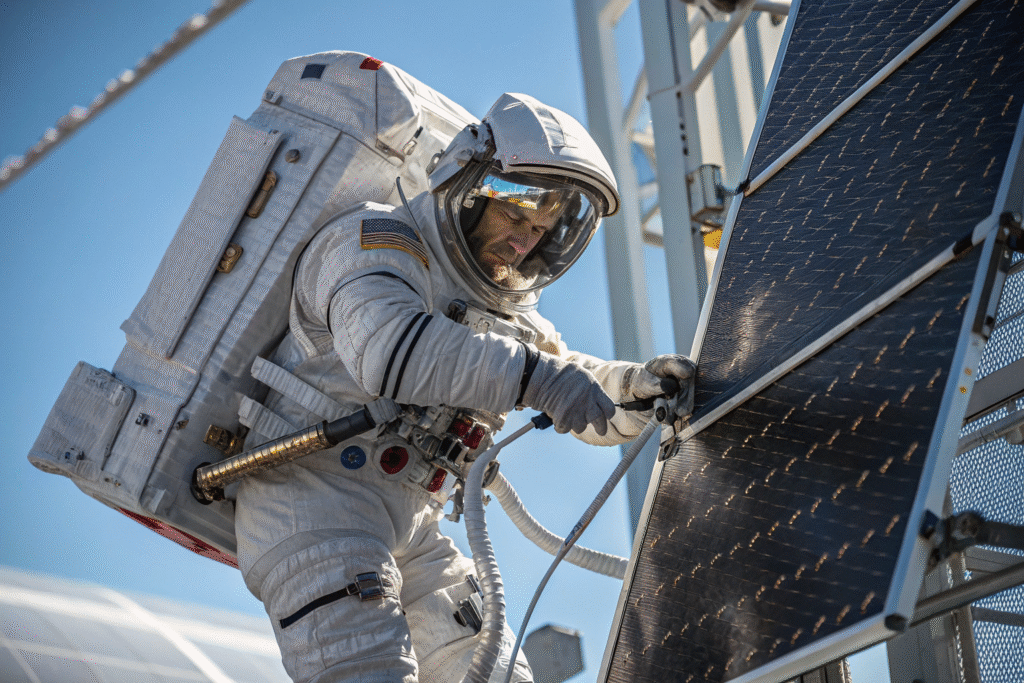

Astronauts need to move freely while working outside spacecraft. Compared to ultra-stiff fibers, Vectran maintains cut resistance while allowing improved mobility. NASA has tested Vectran in spacesuit gloves to reduce hand fatigue, ensuring astronauts can handle tools with better grip and flexibility than older designs that relied solely on Nomex®.

How Does Vectran® Improve Cut Resistance?

One of the greatest risks astronauts face is accidental cuts from sharp tools or micrometeoroid fragments. A small tear can compromise the entire suit’s pressure integrity.

Vectran® offers superior cut resistance that surpasses many traditional aerospace fibers, making it a reliable choice for outer protective layers of space suits.

What Role Does Cut Resistance Play in Safety?

Cut resistance is critical because even a millimeter-wide tear can cause depressurization. Vectran provides a barrier against sharp surfaces, protecting astronauts when they handle space tools, panels, or fasteners. Studies published by NASA have shown that gloves reinforced with Vectran layers drastically reduce the number of glove puncture incidents during extravehicular activities (EVAs).

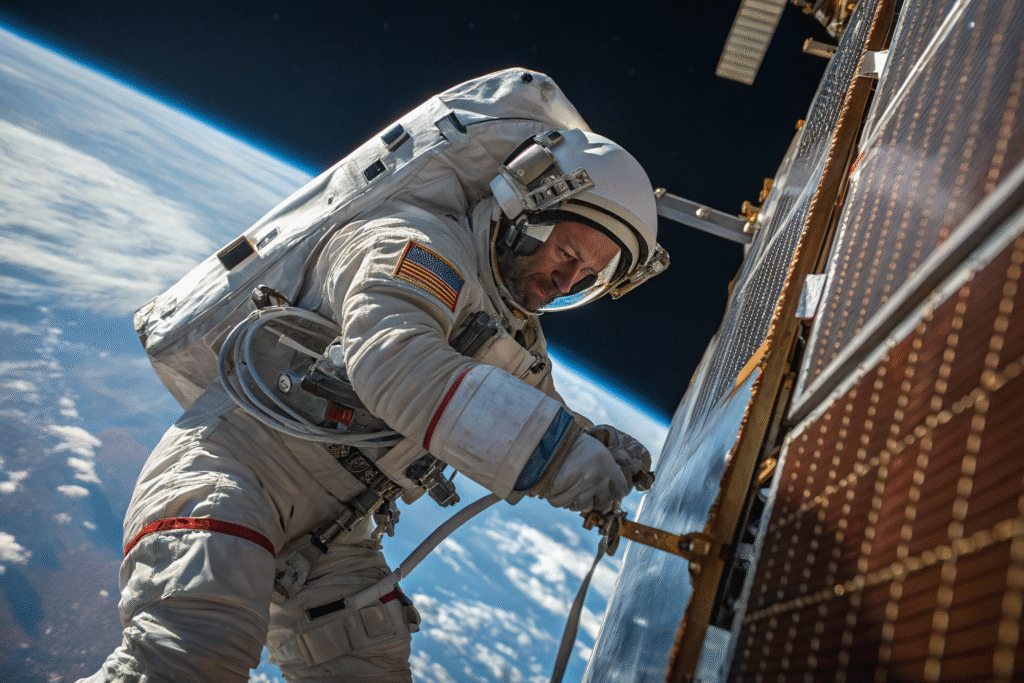

How Does Vectran Perform in Space Conditions?

Vectran retains its cut resistance even in the vacuum of space and under drastic temperature swings ranging from -150°C to +120°C. Unlike weaker synthetic fibers that become brittle in such extremes, Vectran remains tough and dependable, making it a crucial element in advanced suit design.

Is Vectran® Resistant to Space Environment Challenges?

Space is unforgiving. Suits must withstand radiation, UV exposure, and repeated flexing.

Vectran® demonstrates excellent stability against UV radiation and minimal creep, which means it holds its shape and strength even under constant stress.

How Does It Handle UV and Radiation Exposure?

Many fibers weaken under prolonged UV exposure, but Vectran shows better endurance than materials like nylon or polyester. This makes it suitable for the harsh solar radiation astronauts encounter during EVAs. Its resistance to degradation ensures longer operational life and fewer suit replacements.

Can Vectran Withstand Thermal Cycling?

Space suits face continuous thermal cycling when astronauts orbit from sunlight into shadow. Vectran’s liquid crystal polymer structure allows it to maintain consistent strength, unlike some fibers that expand, shrink, or lose resilience under repetitive cycles. This property enhances safety and reliability in long missions.

Why Is Vectran® Preferred for Future Space Missions?

As space exploration expands to longer lunar stays and Mars missions, safety requirements become stricter.

Vectran® offers unmatched durability, making it a preferred fiber for next-generation space suits that demand higher levels of reliability and adaptability.

How Has NASA Used Vectran in Space Suit Prototypes?

NASA has already used Vectran in suit gloves to reduce injuries and enhance performance during EVAs. The lessons learned from these applications are being integrated into advanced prototypes for lunar missions under the Artemis program.

What Makes Vectran Suitable for Mars Missions?

Mars exploration will expose astronauts to rough surfaces, dust storms, and long-term mission timelines. Vectran’s abrasion resistance and long-term durability provide reliable protection against these conditions. Combined with other materials, it can help engineers design multi-layer suits that balance cut resistance, thermal insulation, and flexibility.

Conclusion

Vectran® fiber stands out as one of the most promising materials for enhancing astronaut safety. Its superior cut resistance, flexibility, UV stability, and thermal endurance make it ideal for the extreme conditions of space. As missions extend beyond Earth orbit, fibers like Vectran will continue to play a vital role in protecting human explorers.

If you are in the advanced textiles or aerospace sector and want to explore high-performance fiber applications, our company Shanghai Fumao specializes in custom technical fabrics and fiber integration. To discuss collaboration on next-generation cut-resistant textiles, please contact our Business Director Elaine at elaine@fumaoclothing.com.