Modern consumers expect more from rainwear than just staying dry—they want it to breathe. Whether it’s for hiking, biking, or daily commuting, breathability in rainwear reduces clamminess and keeps the body dry from both external rain and internal sweat. That’s where air permeability testing becomes a critical factor.

This article explains what air permeability means, why it matters in rainwear, how it's tested (ASTM D737, ISO 9237), and where to find suppliers offering rainwear fabrics optimized for airflow without sacrificing water resistance.

What Is Air Permeability and Why It Matters?

Air permeability refers to the rate at which air passes through a fabric under controlled pressure. It’s typically measured in units like cubic feet per minute (CFM) or liters per second per square meter (L/s/m²). In rainwear, it directly influences comfort and thermoregulation.

Why Is It Crucial for Rainwear?

Without air permeability, rain jackets trap sweat, creating a sauna-like environment. This leads to:

- Overheating and excessive sweating

- Condensation build-up on inner layers

- Decreased user comfort and satisfaction

That’s why even premium waterproof-breathable fabrics like Gore-Tex®, eVent®, or Pertex® publish breathability specs derived from air permeability or MVTR tests.

Learn about waterproof-breathable principles at Outdoor Gear Lab and standards from Gore-Tex Lab Testing.

How Does It Differ from Moisture Vapor Transmission?

While MVTR (moisture vapor transmission rate) measures how fast water vapor passes through a membrane, air permeability measures actual airflow through pores or micro-gaps in the fabric. Both affect comfort—but air permeability gives immediate airflow feedback.

Compare definitions and use cases via Testex Textile Standards and OEKO-TEX testing methods.

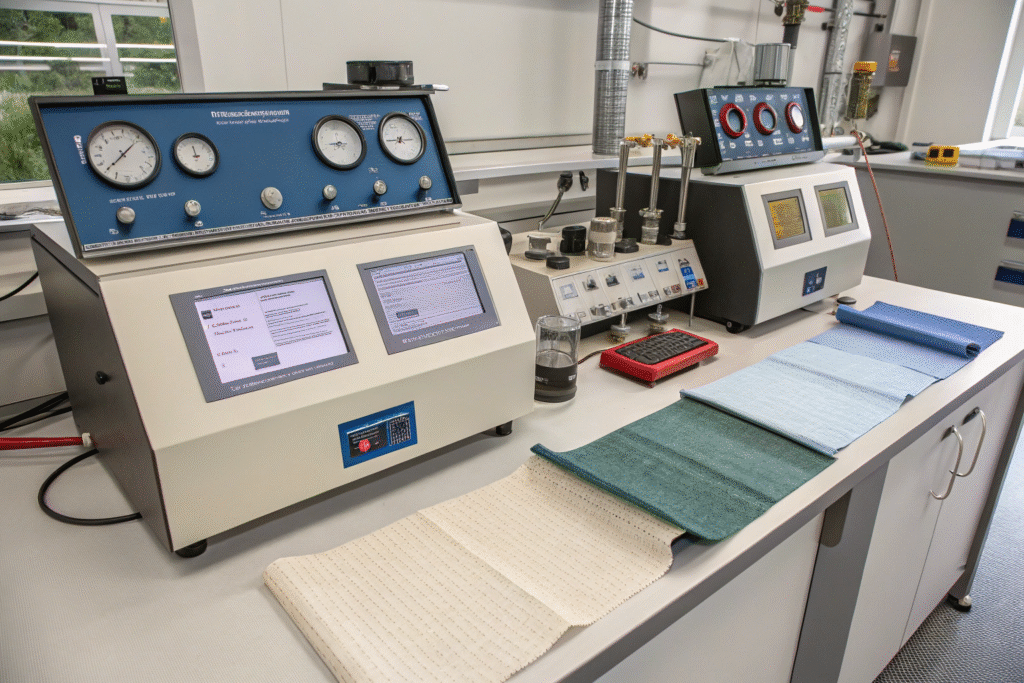

How Is Air Permeability Tested?

There are standardized test methods that quantify how breathable a fabric is. Results are used by outdoor brands, military gear manufacturers, and garment tech developers to calibrate performance levels.

ASTM D737 (US Standard)

This is the most widely accepted method for woven and knitted fabrics. Key points:

- Sample area: 38.3 cm²

- Test pressure: 125 Pa (0.5 inch H₂O)

- Result unit: CFM or L/m²/s

A high rating (e.g., >10 CFM) indicates better breathability. Ultra-tight laminates may score <1 CFM.

Detailed method: ASTM D737 PDF at ASTM.org and summary at SGS Testing.

ISO 9237 (Global/EU Standard)

Similar to ASTM but adapted for different pressure and area specifications. Used in Europe, especially in military and industrial rainwear.

- Test pressure: Typically 100 Pa

- Applications: Waterproof coatings, tents, technical linings

Find more at ISO.org and Intertek fabric test guidance.

What Fabrics Balance Waterproofing with Breathability?

The challenge with rainwear is combining hydrophobic performance (to repel rain) with enough breathability for sweat vapor and air exchange. That’s where fabric engineering—especially membrane and lamination techniques—comes in.

Which Types of Fabrics Perform Best?

-

3-Layer Laminates with Microporous Membranes

- Example: Gore-Tex® Pro, eVent® DV

- Air permeability: ~0.1–1.0 CFM

- Best for mountaineering & pro outerwear

- Source: Gore Fabrics

-

DWR-Coated Softshell with Mechanical Stretch

- Example: Nylon/elastane blends

- Air permeability: ~5–12 CFM

- Ideal for active sports & milder rain

- Source: Polartec NeoShell

What’s the Trade-Off?

- Higher air permeability = better comfort, less rainproofing

- Lower permeability = more rain blocking, less sweat relief

Balance is achieved using perforated membranes, laser vents, or zonal fabric mapping. Learn from Outdoor Industry Association and REI’s rainwear breakdown.

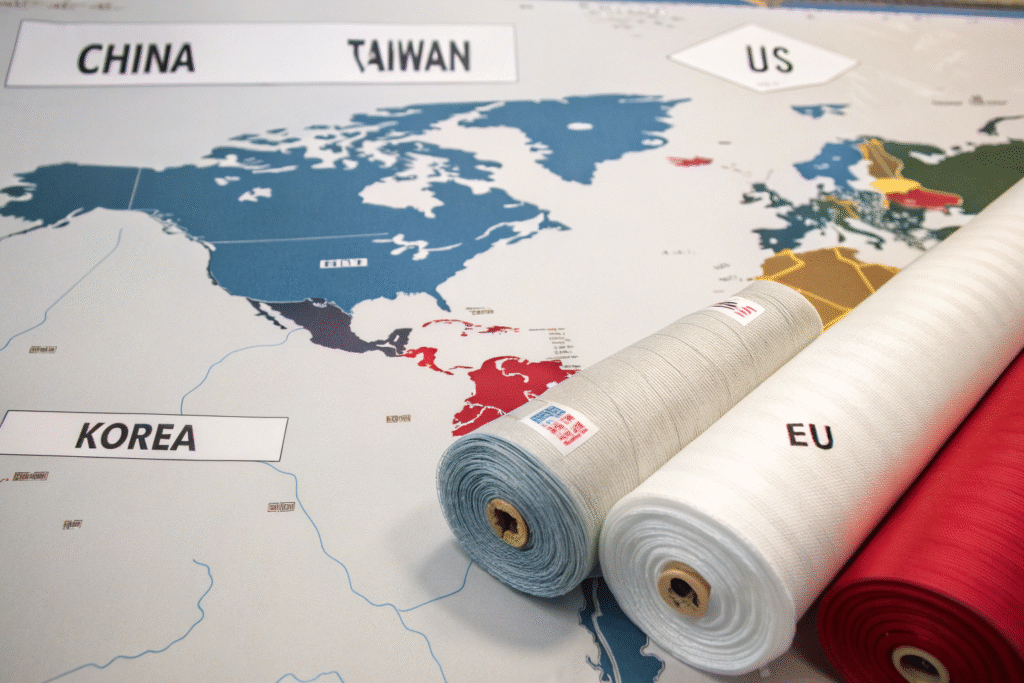

Where to Source Breathable Rainwear Fabric?

Brands and designers can find breathable waterproof fabrics from both premium and budget suppliers—depending on intended application (technical, consumer, corporate gear).

Top China & Asia-Based Sources

-

Fumao Textile (Shaoxing, China)

- Supplies PU-laminated polyester with 2–10 CFM range

- MOQ: 500m, DWR, seam-sealing coating available

- fumaofabric.com

-

Wujiang Sanyuan Textile

- Offers 3-layer nylon + TPU breathable membranes

- ISO + OEKO-TEX certified

- sanyuantex.en.alibaba.com

-

Taiwanese Coated Textile Mills (e.g., EverSmile, Singtex)

- Eco-certified breathable membranes

- Recycled PET rainwear fabrics

- singtex.com

US & EU Performance Textile Sources

-

Schoeller Textil (Switzerland) — Offers breathable rainwear tech with stretch

schoeller-textiles.com -

Toray International (Japan/US) — Known for Dermizax™ waterproof-breathables

toray.us -

Milliken Performance Fabrics (USA) — Workwear and public safety waterproof linings

milliken.com

All reputable suppliers can provide air permeability test data upon request or per contract spec.

Conclusion

For anyone designing or sourcing rainwear, air permeability testing isn’t optional—it’s essential. It determines how breathable your fabric is, how comfortable it feels in action, and ultimately whether your customer will wear it again.

From ASTM D737 to ISO 9237, breathable rainwear fabric must pass objective air flow standards without compromising water resistance. Whether you're prototyping an eco-conscious commuter shell or producing military-grade rain suits, start with air permeability data to get performance right from the beginning.

To request swatches or testing specs from a supplier offering breathable rainwear fabrics with verified permeability ratings, contact elaine@fumaoclothing.com.