Pilling—those annoying little fiber balls on your garments—can ruin the look and comfort of otherwise high-quality fabric. For global sourcing professionals, it’s more than just a nuisance. It’s a potential return rate trigger, a customer service headache, and a clear indicator of textile durability. So how do you trust a supplier’s pilling test results? And more importantly, what does ASTM D3512 really mean for your product?

ASTM D3512 is a standardized method to measure fabric pilling using a Random Tumble Pilling Tester. Evaluating results correctly requires understanding test parameters, interpretation of grade scales, supplier credibility, and relevance to your fabric's end-use.

In this guide, I’ll walk you through everything from how the test is conducted to what the numbers actually mean—and how to push your suppliers for transparent, reliable data.

What Is ASTM D3512 and How Does It Work?

Before you can evaluate a supplier’s test report, you need to understand how ASTM D3512 works in the real world. It’s one of the industry’s most widely accepted standards for synthetic and knit fabrics, especially for sportswear, fleece, and blends prone to pilling.

ASTM D3512 measures the resistance of textile fabrics to pilling by tumbling them randomly in a cork-lined chamber and then visually grading the surface change. Results are reported on a scale of 1 (severe pilling) to 5 (no pilling).

What Makes ASTM D3512 Unique?

Unlike Martindale or ICI methods, ASTM D3512 simulates random wear patterns through cork tumbling and pressurized air, which better mimics real-world usage. It is especially useful for:

- Synthetic knits (polyester, spandex, etc.)

- Performance fabrics used in leggings, tees, uniforms

- Double-brushed and fleece fabrics

You can explore the exact testing procedure on ASTM’s official D3512 documentation page.

How Is the Test Conducted?

The test typically involves:

- Preparing 4 specimens of fabric.

- Placing them inside a cork-lined drum.

- Tumbling at 1200 rpm for 30 minutes.

- Comparing the resulting surface to standardized pilling photo charts.

Labs such as Intertek and SGS offer this test globally, often with extra grading sessions for QC validation.

How to Read and Interpret Pilling Grades?

Seeing a test report with a number on it isn’t enough. You need to understand the grading scale and match it with your customer expectations. ASTM D3512 uses a visual comparison method for grading.

The pilling scale ranges from 1 to 5, with 5 meaning no visible pilling and 1 indicating heavy surface fuzzing and balling. Buyers typically accept grades of 3.5 or higher depending on fabric use.

What Does Each Grade Mean in Practical Terms?

| Grade | Description | Acceptable Use |

|---|---|---|

| 5 | No visible pilling | Premium wear, formalwear |

| 4 | Slight fuzzing | High-end sportswear, officewear |

| 3 | Moderate pilling | Casual knits, loungewear |

| 2 | Significant pilling | Reject in most applications |

| 1 | Severe pilling | Rejected for bulk |

For visual references, see the AATCC Photographic Pilling Standard, which is commonly used to cross-check grades.

What Affects Final Results?

Fabric structure, yarn twist, and finish significantly impact pilling scores. For instance:

- Air-jet spun yarns show less pilling than ring-spun.

- Tightly knit polyester outperforms loose brushed knits.

- Enzyme-washed cottons score better than untreated ones.

These factors must be considered alongside supplier reports. For more scientific background, ScienceDirect has peer-reviewed studies on textile pilling behavior.

What Supplier Behaviors Signal Reliable Test Data?

Many suppliers will claim “4.5 grade anti-pilling” in catalogs, but without proper documentation, that number is meaningless. Verification is crucial, especially when bulk quality may differ from lab-tested prototypes.

Reliable suppliers will present original third-party lab test reports (SGS, ITS, etc.), allow you to verify lab credentials, and clearly state the testing method, parameters, and sample batch origin.

What Questions Should You Ask the Supplier?

Use this checklist:

- Can you share the full ASTM D3512 report including lab name and sample reference?

- Was the test done on production batch or lab sample?

- How many cycles were tested? (Common: 30 mins, but can vary)

- Was the fabric pre-treated (washed, brushed, etc.)?

Cross-check data using platforms like Oeko-Tex Verified Suppliers or Alibaba Verified Supplier pages.

What Red Flags Should You Watch For?

- No lab name or report date.

- Results like “Grade: 5+” (ASTM scale only goes to 5).

- Discrepancies between test results and fabric hand feel.

- No matching batch info or yarn/fiber specifications.

At Fumao Fabric, we ensure all pilling reports come with QR-traceable lab ID and link each swatch to its dye lot and production window. This is essential for apparel brands doing mass rollouts.

How Do Pilling Results Impact Sourcing Decisions?

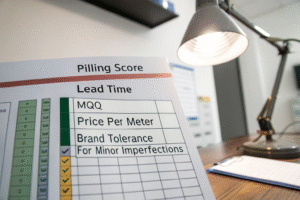

A strong pilling score should never be viewed in isolation. You must weigh it alongside lead time, MOQ, price per meter, and your brand’s tolerance for minor imperfections.

Buyers should set minimum acceptable pilling grades by end-use category and align them with product pricing. For high-contact apparel, a grade below 3.5 can trigger customer complaints and returns.

What’s the Threshold for Different Apparel Types?

| Category | Recommended Minimum Grade |

|---|---|

| Kidswear | 4.0–5.0 |

| Leggings / Activewear | 3.5–4.5 |

| Pajamas / Loungewear | 3.0–4.0 |

| Fashion Tops | 3.5–5.0 |

| Uniforms / Workwear | 4.0+ |

These are based on our export experience with brands in Germany, Russia, and the U.S., and buyer benchmarks listed on TÜV Rheinland audits.

How Do You Balance Price vs Performance?

Sometimes, a supplier with a Grade 3.8 result may still be a better fit due to:

- Faster lead times.

- Lower MOQ.

- Better price by 15–20%.

In these cases, adding enzyme wash, anti-pilling softeners, or even double-side brushing may offset lower scores. See Textile Today for practical methods to finish fabrics and boost pilling grades.

Conclusion

Understanding and evaluating ASTM D3512 test results isn’t just a technical chore—it’s a strategic decision. By asking the right questions, requesting original reports, and matching results to end-use expectations, buyers can protect product quality and brand reputation.

At Fumao Fabric, we integrate third-party lab testing, QR-coded quality reports, and end-use grading guidance into our sourcing process. This helps our global clients—from sportswear startups to uniform giants—make confident decisions even under tight timelines.

Need help analyzing a supplier’s pilling report or testing your new collection? Contact our Business Director Elaine at elaine@fumaoclothing.com and we’ll make sure your fabrics stand up to scrutiny—and your customers’ daily wear.