Corduroy, once a staple of ‘70s workwear and ‘90s streetwear, is now enjoying a well-earned comeback—especially in the vintage and retro-inspired fashion segment. Its distinctive ridged surface and rugged durability make it perfect for outerwear, trousers, accessories, and even home furnishings.

Sourcing heavy-duty corduroy fabric requires evaluating wale count, fiber blend, abrasion resistance, and dyeing stability—ideally from a supplier familiar with retro aesthetics and robust finishing techniques. Whether you're creating a capsule collection or outfitting a heritage menswear brand, quality sourcing is key.

As a fabric producer rooted in Keqiao, we’ve seen a sharp rise in inquiries for vintage-grade corduroy. Below, I’ll guide you through the sourcing process—from construction types to supplier selection and global logistics.

What Defines Heavy-Duty Corduroy in Vintage Fashion?

Corduroy isn’t just one fabric—it varies in weight, wale width, finish, and fiber content. When designers refer to "heavy-duty corduroy," they often mean a dense, structured version with wide wales and high GSM.

Heavy-duty corduroy typically features 6–8 wales per inch, 300–500 GSM weight, and cotton or cotton-poly blends—ideal for vintage coats, structured pants, or rugged accessories.

How Is Wale Count Related to Vintage Aesthetics?

Wale refers to the vertical ridges on corduroy. Wider wales (lower wale numbers) give the fabric a chunkier, retro look associated with 1970s tailoring or early hip-hop streetwear. For instance, 6-wale corduroy offers that bold ribbed texture favored in oversized blazers and utility jackets.

We recommend wide-wale corduroy for outerwear, and fine 14–16 wale for shirts or accessories. Our dyeing partners specialize in pigment washes that further evoke a "worn-in" vintage feel. Check this style guide for inspiration.

What Fabric Weight Is Ideal for Heavywear?

Look for 350–450 GSM for fall/winter garments or rugged pants. Below 300 GSM, corduroy loses the structure that defines vintage styles. We produce 100% cotton and cotton-spandex versions with brushed backs for added softness. All rolls are tested for Martindale abrasion resistance to ensure long-lasting performance.

Where Are the Best Regions to Source Corduroy Fabric?

Sourcing location matters—both for fabric quality and shipping efficiency. Several textile regions are globally known for their corduroy production due to established looms, dyeing expertise, and historical knowledge of pile weaves.

China, Turkey, and Pakistan remain the leading exporters of heavy-duty corduroy, each with different strengths in price, finish, and MOQ flexibility.

Why Is Keqiao, China Ideal for Corduroy Buyers?

As one of the world’s largest textile hubs, Keqiao offers unparalleled corduroy options across weights, blends, and finishes. At Fumao, we produce over 20 SKUs of corduroy—from solid pigment-washed 8-wale cotton to printed 14-wale poly-cotton blends.

We’ve helped vintage brands from the US and UK source rolls with precise GSM and wash targets. Our full-package services include lab dips, embossing, and custom digital printing on wide-width rolls.

What About Turkish or Pakistani Mills?

Turkey is known for its vertically integrated corduroy factories. Mills like Bossa offer organic-certified, garment-dyed options. Pakistani suppliers often provide good value for mid-weight corduroy and stock greige for buyers seeking custom dyeing.

However, challenges like longer lead times and political instability can complicate logistics. We frequently consolidate raw fabric from multiple regions into our China facility for inspection and export via Silk Road rail or ocean freight. See logistics comparisons here.

What Finishes or Treatments Matter for Retro Styles?

Corduroy’s aesthetic appeal is largely tied to how it’s finished. Retro-inspired fashion calls for faded tones, slightly uneven texture, and soft handling—traits that aren’t naturally present in raw corduroy off the loom.

Treatments like pigment dyeing, enzyme washing, and mechanical brushing add softness, aged color gradients, and the relaxed vibe crucial for vintage collections.

What Is Pigment Dyeing and Why Is It Popular?

Pigment dyeing deposits color on the surface of the fabric, creating a faded, “lived-in” effect over time. It’s especially effective on corduroy, where the pile reacts differently to dye, enhancing tonal variation. Check out this dyeing guide for basics.

At Fumao, we use eco-certified pigment systems with optional silicon softeners. We offer lab dips in vintage palettes like olive, rust, and mustard—popular among US and EU menswear brands.

Do Enzyme and Stone Washing Work on Corduroy?

Yes, but with caution. Enzyme washes reduce stiffness and enhance drape, while stone washing creates physical abrasion for a worn look. Both require controlled settings to avoid pile flattening or shrinkage. We’ve developed a low-impact stone-wash method that preserves wale depth and improves handfeel. Learn more on wash techniques.

How Do You Manage MOQ and QC in Vintage Corduroy Orders?

Sourcing specialty fabrics like heavy corduroy often involves smaller batch orders, custom dyes, and specific weave specs. That’s why managing MOQ (minimum order quantity) and QC (quality control) is critical—especially for small to mid-sized vintage brands.

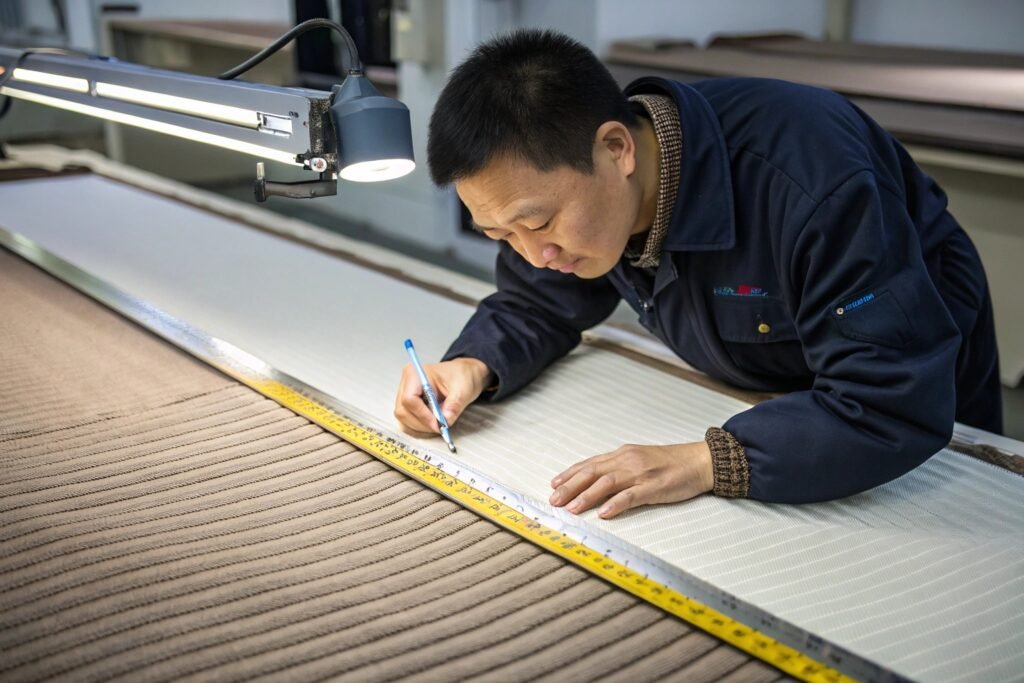

Work with suppliers who offer small-batch development, in-house QC, and visual tracking systems for dye lots, texture consistency, and inspection results.

Can You Order Small Quantities of Custom Corduroy?

Yes. At Fumao, our MOQ for custom-dyed 8-wale cotton corduroy starts at just 300 meters per color. We offer pre-dyed stock for as low as 100 meters. For clients running pop-ups or test runs, we recommend using our pre-finished rolls and adjusting trims locally. Read about low MOQ sourcing strategies here.

We also support sample yardage runs (10–20m) for fit testing and trial garments. These come with optional swatch cards and Pantone-based dye approvals.

What QC Metrics Should Be Verified?

Key specs include GSM, wale count, shrinkage after washing, and colorfastness. We issue CNAS-accredited lab reports and QR code-based spec tracking. All lots are bulk-inspected against customer-approved standards. For one New York brand, we delivered corduroy with ±3% shade variance across three repeat orders thanks to our dye house’s lab-to-bulk monitoring system.

Conclusion

Heavy-duty corduroy isn't just another textile—it's a statement piece for any vintage-inspired brand. From construction to finishing, sourcing the right corduroy means balancing durability, retro appeal, and supply chain reliability. At Fumao, we help brands of all sizes access small-MOQ corduroy with custom treatments, rigorous QC, and global shipping. Whether you’re reviving 70s tailoring or launching a retro streetwear line, we’ll help you source corduroy that truly stands the test of time.