Uniforms are expected to perform day in and day out—exposed to sweat, UV rays, industrial washing, and mechanical abrasion. But if the color fades quickly, it reflects poorly on the brand and costs businesses more in replacements.

Dope-dyed polyester is the go-to solution for colorfastness in professional and industrial uniforms. It resists fading from light, washing, and chemicals better than conventionally dyed fabric, making it ideal for durable workwear.

As a fabric manufacturer who works with global uniform brands and state procurement tenders, I’ve seen how switching to dope-dyed polyester drastically reduces color complaint rates while keeping long-term costs down.

Let me show you how this technology works—and why so many uniform producers are making the switch.

What Makes Dope-Dyed Polyester More Colorfast?

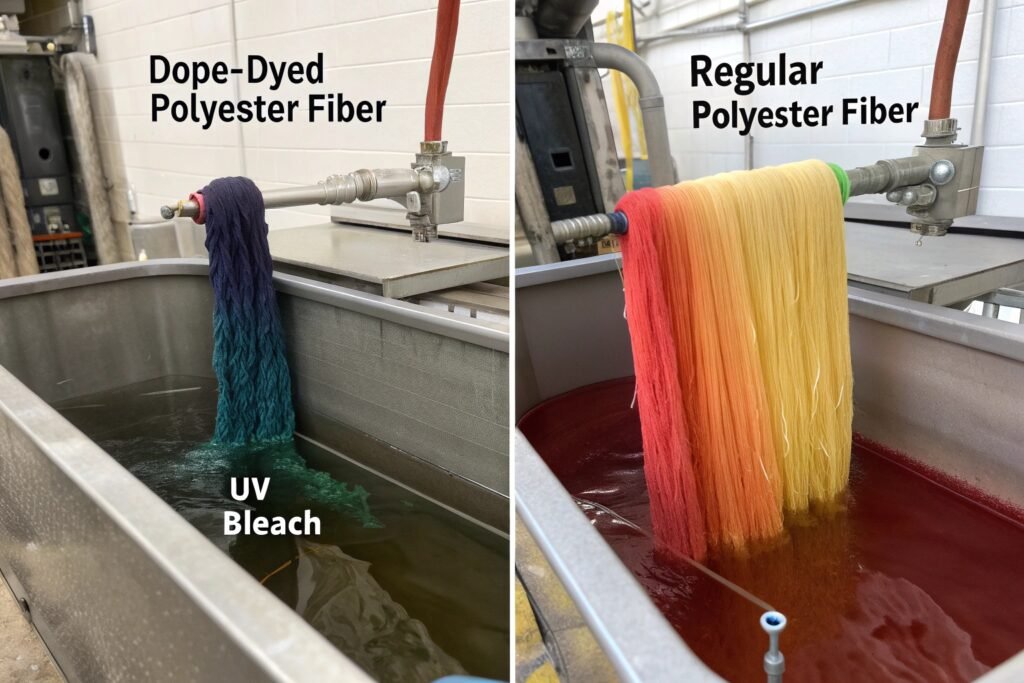

Conventional dyeing involves immersing finished fabric in dye baths. But dope-dyeing (also called solution dyeing) colors the fiber before it's extruded. This embeds pigment directly into the polymer.

This structural difference makes dope-dyed polyester inherently more colorfast—because the color isn’t just on the surface, it’s part of the fiber.

Colorfastness Benefits

| Test Type | Dope-Dyed Polyester | Regular Dyed Polyester |

|---|---|---|

| Light Fastness (ISO 105-B02) | 6–7 | 4–5 |

| Washing Fastness (ISO 105-C06) | 4–5 | 3–4 |

| Rubbing Fastness | 4–5 | 3–4 |

| Chlorine Resistance | Excellent | Moderate |

Brands like Cordura® and Polartec® use solution dyeing for military and tactical gear because of its fade resistance and performance.

How Does Dope-Dyeing Support Sustainability Goals?

Besides durability, dope-dyeing is also greener.

The process eliminates the need for water-heavy dye baths, reducing chemical use, wastewater, and CO₂ emissions. That makes it attractive to ESG-focused uniform buyers and B2B clients.

Environmental Savings

| Factor | Dope-Dyed Polyester | Traditional Dyeing |

|---|---|---|

| Water Usage | 90% less | High |

| Chemical Consumption | 60–80% less | High |

| CO₂ Emissions | Lower (no steam) | Higher |

| Wastewater Generation | Minimal | High |

Certifications like OEKO-TEX® STeP and bluesign® support mills implementing solution dyeing in sustainable textile workflows.

Where Is Dope-Dyed Polyester Most Useful in Uniforms?

From workwear to hospitality to military applications, uniform buyers want garments that look fresh even after months of wear.

Dope-dyed polyester is ideal for high-wear, high-wash applications because it holds color over time, reducing the frequency of replacements.

Best Use Cases

- Healthcare scrubs (hospital-grade chlorine wash cycles)

- Security uniforms (sun + movement + abrasion)

- Corporate uniforms (brand color integrity)

- Construction vests (UV + weather exposure)

- Military/Police (camouflage longevity)

Read case studies from TenCate Protective Fabrics or Milliken Military to see how global clients are switching.

What Should Buyers Ask Suppliers About Dope-Dyed Fabrics?

If you're planning a uniform collection using dope-dyed polyester, make sure you ask the right questions.

Not all solution-dye processes are equal. The quality of the pigment, fiber grade, and testing process impact final performance.

Key Questions for Your Supplier

- Is the pigment UV-stable and heavy-metal-free?

- Do you provide ISO 105-B02 or AATCC 16 test reports?

- What's your MOQ per color?

- Can you match Pantone shades in solution-dye?

- Do you hold GRS or OEKO-TEX® certification?

At Fumao Fabric, we offer CNAS-accredited testing, custom solution-dyeing, and MOQ as low as 800 meters per color, suitable for both bulk programs and DTC brands.

Conclusion

Dope-dyed polyester is the clear winner for colorfastness in uniforms. It outperforms traditional dyeing in light resistance, wash durability, and environmental impact.

For any brand or buyer concerned about uniform color fading, returns, or frequent replacements, choosing dope-dye from a certified supplier ensures lasting performance and consistency.

Reach out to Fumao Fabric today for color cards, lab reports, and cost comparisons for your next uniform development cycle.